Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307972 pipe clamp assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

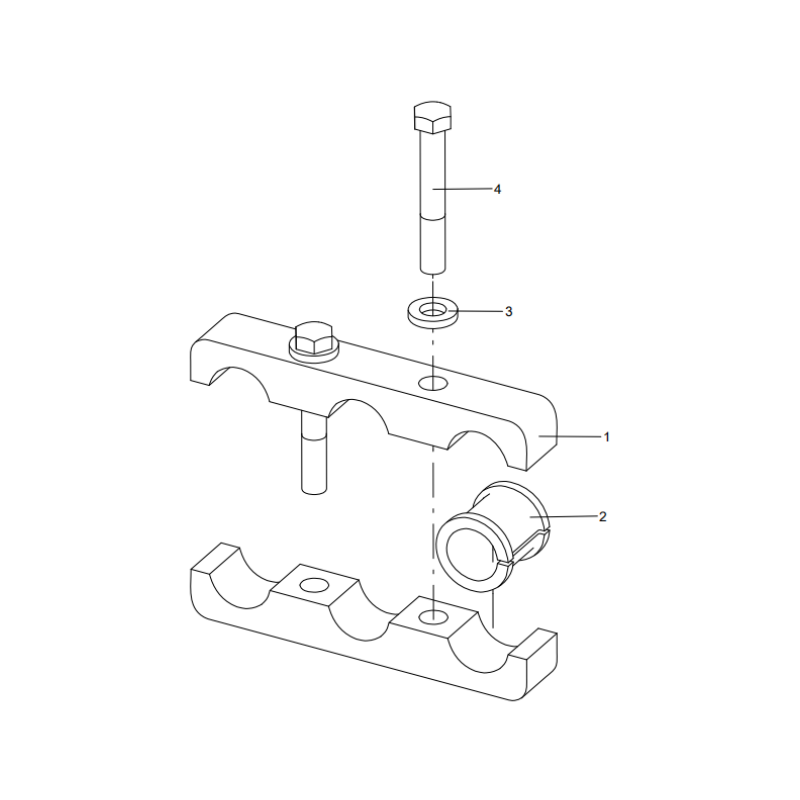

XCMG XE2000 Excavator Pipe Clamp Assembly (Part No. 318307972): The Stable Core of the Piping System

In the global heavy-duty construction field of mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and ultra-large bucket capacity of 10-14m³, has become the “efficiency benchmark” in mining. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, it consistently conquers extreme working conditions with its stable and efficient performance. Within its complex and precise piping system, the pipe clamp assembly (part no. 318307972), as a “system-level solution” for pipe fixing, is a core component ensuring the safe and stable operation of critical pipelines such as hydraulic and fuel lines.

I. Bearing the Heavy Responsibility of Overall Piping System Stability

Cluster Fixing of High-Pressure Pipelines: The XE2000’s hydraulic system operates at pressures up to 35MPa, with multiple high-pressure pipelines simultaneously generating vibrations and pressure shocks during equipment operation. The pipe clamp assembly (318307972) utilizes a modular design to secure multiple pipeline clusters. It can be flexibly combined according to different pipe diameters and layout requirements, orderly fixing high-pressure hydraulic lines, return oil lines, etc., in preset positions on the machine body, preventing pipeline displacement or mutual friction due to resonance. In heavy-duty crushing operations following hard rock blasting, the equipment vibration amplitude increases significantly. This assembly absorbs vibration energy through its overall buffer structure, preventing leakage at pipe interfaces due to continuous impact. Adaptable fixing for complex working conditions: Mining environments present complex factors such as large amounts of dust, slag, and alternating high and low temperatures. The pipe clamp assembly (318307972) features differentiated fixing schemes designed for different pipeline functions—hydraulic lines use high-strength rigid clamps, fuel lines have added insulating buffer layers, and cooling lines are equipped with reserved space for heat dissipation. This precise and adaptable fixing method ensures that in extreme temperature environments ranging from -30℃ to 50℃, the pipelines of each system maintain a stable connection without affecting media transmission efficiency.

II. Superior Performance Designed for Heavy-Duty Systems

High-Strength Materials and Modular Structure: To adapt to the heavy-duty piping system of the XE2000, the main body of the pipe clamp assembly (318307972) is forged from high-strength alloy steel with a tensile strength exceeding 580MPa. Key connectors utilize a combination of anti-loosening nuts and elastic washers. The clamping arms are precision stamped, with the fit error to the pipe’s outer diameter controlled within 0.5mm, ensuring both clamping strength and preventing damage to the pipe surface. After multi-layer composite anti-corrosion treatment, the surface can withstand over 900 hours of salt spray testing, providing long-term resistance to rust in high-humidity, high-dust mining environments.

Optimized Vibration and Noise Reduction Design: XCMG engineers designed a multi-stage vibration damping structure for this pipe clamp assembly through dynamic simulation analysis. The clamping area features an internal oil-resistant rubber buffer pad, and the connection point between the bracket and the machine body utilizes an elastic damping device. This effectively reduces the transmission efficiency of pipeline vibration, lowering the overall pipeline system’s operating noise by more than 15%. Compared to traditional single-pipe clamps, its vibration fatigue life is increased by 40%, maintaining stable fixing performance throughout the equipment’s entire lifespan.

III. Quality and Service Assurance Under Stringent Testing

System-Level Performance Limit Testing: Each batch of pipe clamp components (318307972) undergoes rigorous system-level testing before leaving the factory: a static load test at 1.5 times the rated clamping force (no deformation for 60 minutes), a random vibration test of 1 million cycles (simulating 8 years of operating conditions), a high and low temperature cycle test from -40℃ to 120℃ (no functional failure after 500 cycles), and an oil corrosion resistance test (no aging after immersion in hydraulic oil for 1000 hours). This series of stringent tests ensures the long-term reliability of the product under extreme operating conditions. In mining construction, where “details determine efficiency,” the XCMG XE2000 excavator pipe clamp assembly (part number 318307972) provides a systematic fixing solution to safeguard the safe operation of pipeline systems. Choosing this original equipment manufacturer (OEM) pipe clamp assembly not only reduces the risk of pipeline failures but also improves the overall stability of equipment operation, continuously creating value for your mining production. Let XCMG’s original quality be your reliable guarantee for heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307972 pipe clamp assembly XCMG XE2000 excavator spare parts

1 318307869 2 PIPE CLIP

2 318307873 1 SPRING WASHER

3 329900303 2 THICKENED FLAT WASHER

4 805046645 2 BOLT M12×80