Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307873 spring washer XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Spring Washer (Part No. 318307873): The Guardian Against Loosening in Connections

In the global heavy-duty construction field of mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and large bucket capacity of 10-14m³, has become a “core piece of equipment” in mining operations. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, it consistently conquers extreme working conditions with its stable and efficient performance. Among its millions of precision connection points, the spring washer (part no. 318307873), as the “anti-loosening barrier” of the fastener system, is a core small component that ensures the reliability of connections for critical components.

I. Bearing the critical mission of preventing loosening in connections

Security assurance under extreme vibration: During heavy-duty excavation operations, the various components of the XE2000 machine body will experience continuous and severe vibrations. Traditional flat washers are insufficient to resist the risk of bolt loosening caused by long-term vibration. The spring washer (318307873) utilizes a unique elastic deformation design to generate a continuous elastic preload after the bolt is tightened, firmly locking the bolt and nut connection surface and effectively counteracting the loosening torque caused by vibration. In hard rock blasting operations, where equipment vibration amplitude can reach more than three times that of conventional conditions, this spring washer maintains a stable anti-loosening effect, preventing component displacement or functional failure due to bolt loosening.

Multi-scenario sealing assistance: In addition to its core anti-loosening function, this spring washer can also fill microscopic gaps in the connection surfaces of hydraulic pipeline flanges, engine accessories, and other joints through elastic deformation, further enhancing sealing performance. In high-dust, high-humidity environments such as mines, it reduces the risk of dust and moisture intruding into components through connection gaps, providing additional protection for core components such as hydraulic and transmission systems.

II. Superior Performance Designed for Heavy-Duty Applications

High-Strength Materials and Precision Machining: To meet the heavy-duty connection requirements of the XE2000, the spring washer (318307873) is made of high-strength spring steel with a Rockwell hardness of 45-50 HRC, and its elastic limit far exceeds that of ordinary industrial washers. The washer edges are precisely chamfered to prevent scratching bolts or connection surfaces during installation; after anodizing and blackening for corrosion protection, the surface can withstand salt spray testing for over 500 hours, providing long-term resistance to rust in high-humidity mining environments and ensuring no degradation in elastic performance. Precisely Fitting Structural Parameters: XCMG engineers precisely designed the thickness, unfolded length, and elastic coefficient of the spring washer based on the bolt specifications and stress characteristics of each key connection point in the XE2000. Its open angle in its free state is controlled between 15° and 20°, ensuring optimal elastic preload after bolt tightening. This prevents loosening failure due to insufficient elasticity or bolt fatigue damage due to excessive elasticity. This precise fit creates a perfect fastening system between the washer, bolt, and nut.

III. Quality and Service Guarantee Under Rigorous Testing

Comprehensive Performance Limit Testing: Every batch of spring washers (318307873) undergoes multiple rigorous tests before leaving the factory: 1000 elastic deformation cycle test (no permanent deformation), 200-hour salt spray corrosion test (no rust spread), elasticity retention test at extreme temperatures (elastic decay rate <5% from -40℃ to 120℃), and vibration anti-loosening performance test (simulating level 8 vibration intensity without loosening). This series of strict tests ensures the long-term reliability of the product under extreme operating conditions. In mining construction, where “details determine safety,” the XCMG XE2000 excavator spring washers (part number 318307873) provide reliable protection for thousands of connection points with their small yet crucial anti-loosening function. Choosing these original factory-customized spring washers not only reduces the risk of failure due to loose bolts but also improves the overall stability of equipment operation, continuously creating value for your mining production. Let XCMG’s original factory quality be your reliable support for heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

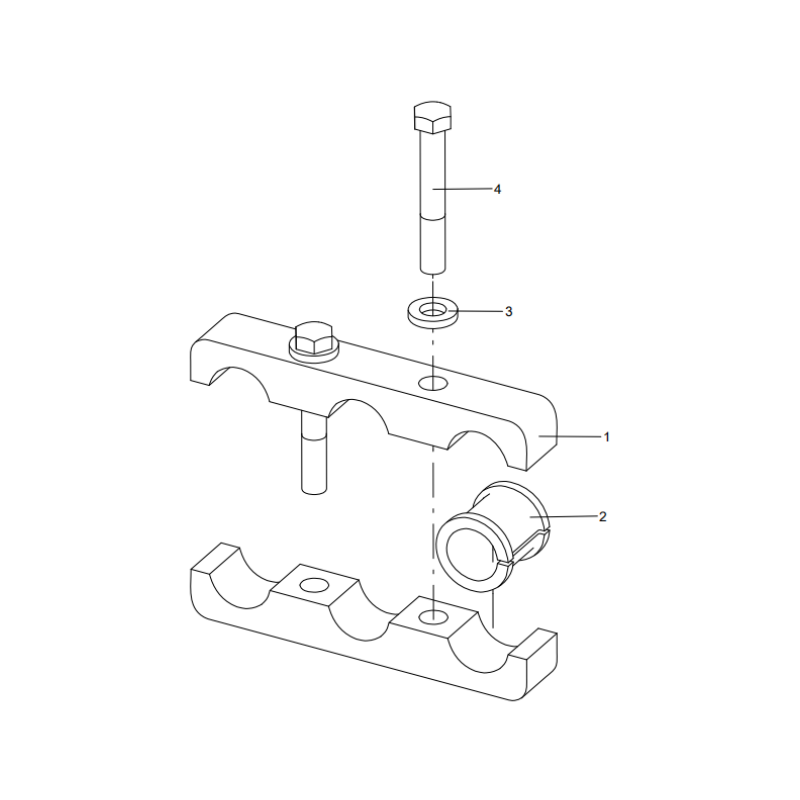

318307972 pipe clamp assembly XCMG XE2000 excavator spare parts

1 318307869 2 PIPE CLIP

2 318307873 1 SPRING WASHER

3 329900303 2 THICKENED FLAT WASHER

4 805046645 2 BOLT M12×80