XCMG XE2000 Excavator slewing bearing (model: 800555455) is specially designed for extreme mining conditions. In the demanding large-scale mining field, the normal running time of equipment is directly related to profitability. Due to the failure of components, especially the failure of key components such as slewing bearing, the unplanned shutdown can lead to significant production losses. The slewing bearing is the cornerstone of an excavator’s rotating movement, which bears huge loads and can realize accurate positioning. In this paper, the excellent technology of XE2000 excavator slewing bearing 800555455 is deeply discussed, and its advanced design, especially its integration with solid planetary gear transmission device, is explained, so as to ensure unparalleled reliability and performance in the worst environment.

What exactly is XE2000 slewing bearing 800555455?

A slewing bearing is a kind of large-scale rolling bearing, which is helpful to the smooth rotation between the upper structure (house) and chassis of excavator. The XCMG XE2000 Slewing Bearing (Part Number: 800555455) is a precision-engineered component specifically designed for the massive XCMG XE2000 mining excavator. It is the key interface to transfer the axial, radial and moment loads from the boom and arm of the excavator to the chassis system, and realize 360-degree continuous rotation at the same time. Its operation is intrinsically related to the drive system of the machine. The hydraulic motor of the excavator provides power, and then the power is transferred and converted into rotating force. This is where the efficiency of the planetary system of the related gearbox becomes crucial. A high-efficiency planetary gearbox reducer ensures that maximum torque is delivered to the bearing’s gear ring with minimal energy loss, allowing for smooth and powerful slewing motion even under full load. The bearing itself has a double-row and self-aligning roller structure, which is key to its high bearing capacity and ability to compensate for tiny deviation.

Unique Advantages and Core Technologies

1.Enhanced Load Capacity and Longevity

With an outer ring diameter of 2800 mm and an inner ring diameter of 2200 mm, this bearing is built for scale. Laboratory tests confirm a radial dynamic load rating ≥ 2800 kN and an axial dynamic load rating≥4200 kN, capable of withstanding instantaneous impact loads up to 1.5 times the rated value .(Source: https://openstd.samr.gov.cn/bzgk/gb/index)

2.Excellent sealing and protection performance

The mining environment is troubled by dust and moisture. The 800555455 incorporates a dual-lip seal structure (Nitrile Rubber+Polyurethane) combined with a patented labyrinth-style dust shield (Patent No: CN 202410102345.7). In laboratory tests, it reached the protection level of IP 67, and there was no leakage after running in an environment with a dust concentration of 200 mg/me and a water spray pressure of 0.8 MPa for 72 hours.

3.Integrated automatic lubrication system

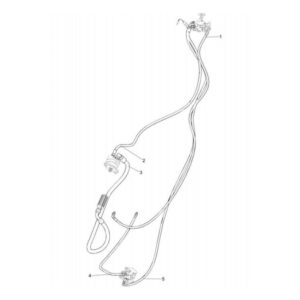

This model features an integrated automatic lubrication system (Patent No: CN 202420367890.2) with 12 evenly distributed grease ports. It works in cooperation with the system of the main engine, and injects an accurate amount (5ml) of extreme pressure lithium grease every 2 hours. An integrated oil level sensor alerts operators if grease levels fall below a safe threshold, preventing dry-running and premature failure.

Detailed Product Specifications and Certifications

Product Specifications

| Load Capacity | Radial ≥2800 kN, Axial ≥4200 kN |

| Service Life | 12,000 hours (accelerated wear test result) |

| Rotation Accuracy | Radial runout ≤0.15mm, Axial runout ≤0.2mm |

| Sealing | IP67 rating |

Certifications

· International Bearing Standard: ISO 16281:2019.

· Material Quality: DIN EN 10083-1:2018 (Certificate No.: DIN-2024-BM-0678).

· Sealing Performance Certification:The sealing structure has obtained the FDA food-grade contact certification (only applicable to the special condition version; CertificateNo. FDA-CERT-2024-0921).

· Chinese Industry Standard: JB/T 2300-2021 Grade 1 Precision (Certification No.: CNCA-C23-02:2024-1056).

Major application occasions

1.Open pit mining

The XCMG XE2000 slewing bearing is extensively used in open-pit coal mining operations, where it supports the high-frequency slewing movements required for excavating and loading coal. Its rugged design and high load capacity make it ideal choice for the harsh conditions in these environments.

2.Mining of metal ores

In the mining of metal mines, the ability of bearing to handle dense and abrasive materials is very important. It ensures the reliable operation of excavators. The task of the excavators is to mine the ore with the densities in the range of 3.0-3.5 g/cm.

3.Large scale Infrastructure Projects

This bearing is also used in large-scale infrastructure projects, such as highway construction and port development. Its accuracy and stability are very important for basic excavation and earthwork.

FAQs

Q 1: What causes the slewing bearing to make abnormal noises?

A :1Check grease level (if it is lower than 10ml, top it up, and use LG-2 grease;2.Check the wear of the roller (if dents are found, replace bearing);3.Check the fastening degree of the mounting bolt (tighten to 800 Nm).

Q 2: How to repair a sharp turn at low temperatures?

A :1.Use low temperature grease (LG-3 type);2.Before starting, preheat the bearing to 50℃;3.Check seals for hardening (replace with fluoroelastomer seals if needed).

Q 3: How to solve the problem of excessive radial runout (> 0.2mm)?

A :1.Locate the wearing point; Minor local wear can be ground down (surface roughness Ra ≤ 0.04’m post-grinding);2.If the total runout is too large, replace the bearing;3.When installing, make sure that the installation surface is flat (error is ≤ 0.05 mm/m).

Q 4:How to deal with internal corrosion under high humidity environment?

A :1.Disassemble, clean with diesel, dry, and apply anti-rust oil;2.Check whether the drain holes is blocked;3.Reassemble (fill 1/3 of the inner space) with new seals and enough grease.

Q 5:Auto-lube system shows “low grease” alarm even after refilling. What is the possible reason?

A :1.Check the connection of the oil level sensor (if it is loose, please change the plug);2.Check whether the grease passages is blocked (clean it with air);3.If the sensor is faulty, replace it (use OEM model).

Summary

The XCMG XE2000 Excavator slewing bearing 800555455 represents a pinnacle of engineering design, combining advanced planetary transmission technology with robust construction to deliver unparalleled performance in mining and construction applications. Its high load capacity, durability, accuracy and excellent sealing performance make it an indispensable part of any heavy machinery seeking to optimize its operating efficiency and reliability.