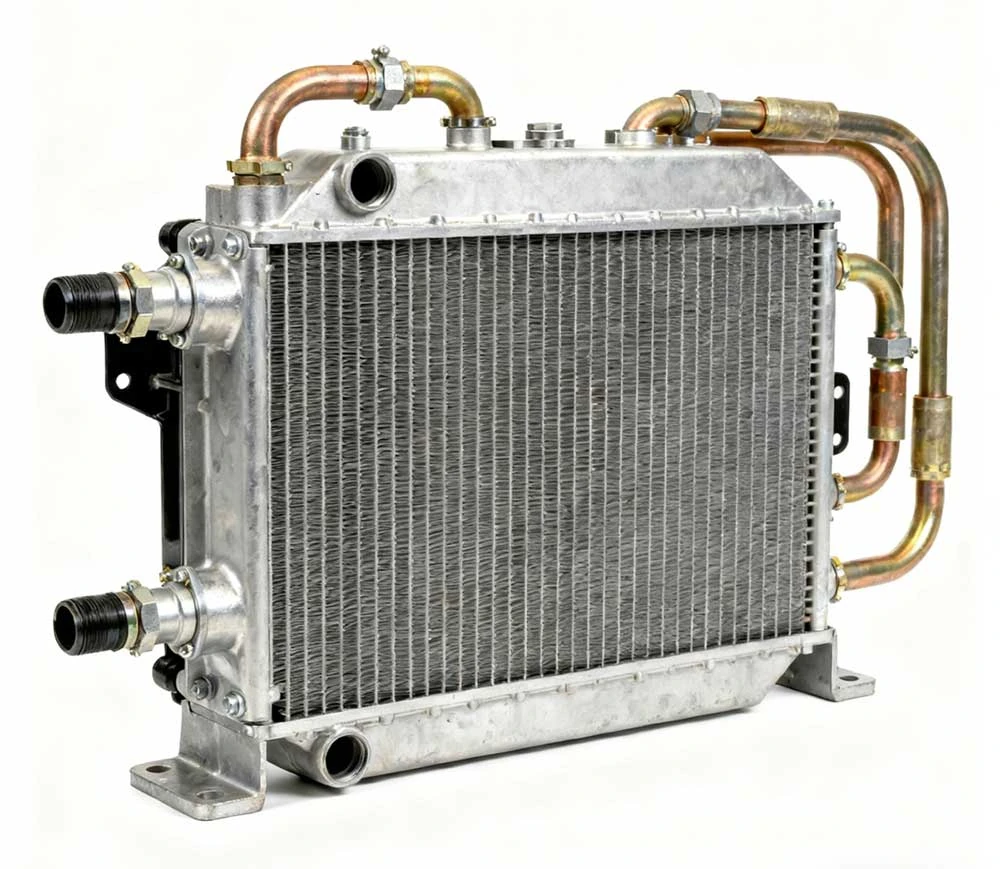

In the world of automotive and heavy – duty machinery, the performance and reliability of the gearbox planetary system are of utmost importance. The planetary gearbox and planetary gear transmission device are key components to realize stable power transmission and efficient operation. 29564138 Allison gearbox oil cooler assembly plays an important role in maintaining the best performance of these systems.

What is the 29564138 Allison transmission oil cooler assembly?

The 29564138 Allison transmission oil cooler assembly is a special component, which is used to regulate the transmission oil temperature of Allison equipped vehicles.

Unique superiority

1.High Temperature performance

One of the greatest advantages of the 29564138 Allison transmission oil cooler assembly is its excellent high temperature resistance. It can operate in a temperature range of – 40℃ to 120℃. In laboratory tests, when placed in a – 40℃ environment for 48 hours, the component showed no signs of cracking.

2.High efficient heat dissipation

The oil temperature of the transmission can be reduced from 110℃ to below 85℃, and the cooling rate is at least 2℃ per minute (third-party testing organization: SGS testing reportNo. SGST-2024-at 0876). This efficient heat dissipation ensures that the planetary gear transmission device operates in a safe temperature range, thus prolonging its service life and performance.

3.High Pressure Resistance performance

29564138 Allison transmission oil cooler assembly has a maximum working pressure of 1.8 MPa, and its rupture pressure is greater than or equal to 4.5 MPa. This high – pressure resistance makes it capable of handling the high – pressure conditions that often occur in heavy – duty vehicles and machinery.

4.The flow resistance is low

When the oil flow rate is 20 l/min, the flow resistance of the oil cooler assembly is less than or equal to 0.25 MPa, which is 30% lower than the industry average level.

5.Superior corrosion resistance

After 1000 hours of neutral salt spray test (GB/t 10125-2021), the corrosion area on the surface of the parts is less than or equal to 5%, and the sealing rubber hoses shows no signs of aging or cracking. This excellent corrosion resistance ensures its long-term reliability, especially in the environment with high humidity or high salt content, such as coastal areas.

Specification of product

| Parameter | Details |

| Temperature Resistance Range | – 40℃~ 120℃ |

| Heat Dissipation Power (Under Standard Conditions) | ≥ 8.5 kW (Ambient temperature: 25℃, Oil flow rate: 15 liters/minute) |

| Maximum Working Pressure | 1.8 MPa |

| Rupture Pressure | ≥ 4.5 MPa |

| Flow Resistance (at 20 liters/minute) | ≤ 0.25 MPa |

| Corrosion Resistance | Surface corrosion area ≤ 5% after 1000-hour neutral salt spray test (GB/t 10125 – 2021) |

| Certification Standards | CE 2014/35/EU (LVD Directive), DOT FMVSS 108, ISO 9001:2015 (Quality Management System), IATF 16949:2016, CCC C2401 – 2023 |

Major application scenarios

1.Commercial vehicle

The main customers in this industry are heavy – duty truck fleets (such as SF Express Logistics and Deppon Logistics) and urban bus groups. The average daily mileage of this kind of vehicles exceeds 300 km, and the gearbox is in a state of high load for a long time, which requires high thermal stability.

2.Construction machinery

The core customers are mining enterprises (such as China Shenhua) and infrastructure construction companies.The dustproof design and high temperature heat dissipation performance of this product can meet the requirements of heavy load operation for 12 hours continuously.

3.Special purpose vehicle

It mainly includes fire engines (such as fire rescue in China), ambulances and garbage trucks. In a fire fighting operation, a fire truck equipped with this oil cooler can maintain stable performance throughout the five-hour operation without any overheating-related problems.(Source: https://www.119.gov.cn/)

FAQ’s

Q 1: What are the possible causes of oil leakage in the oil cooler, and how to solve them?

A 1: Common causes:①Aging of interface gaskets (used for more than 5000 hours);②core deformation caused by external force;③the bolt is loose (due to vibration). Solutions:①Replace the original gasket (model number: 29564139);②check the appearance of iron core. If it is deformed, replace the whole assembly;③retighten the interface bolts according to the torque standard (25 Nm).

Q 2: How to eliminate the failure of cooling efficiency decline and high oil temperature?

A 2: Troubleshooting steps:①Clean the core heat sink (blow off dust with compressed air, and avoid direct flushing with a high-pressure water gun);②check the oil level (if it is insufficient, please replenish Allison original transmission oil);③test the temperature control valve (replace the valve assembly if it doesn’t open when the oil temperature ≥ 90 ° c);④check whether the oil circuit is blocked (judged by oil pressure test). If flow resistance exceeds 0.3 MPa, remove and clean it).

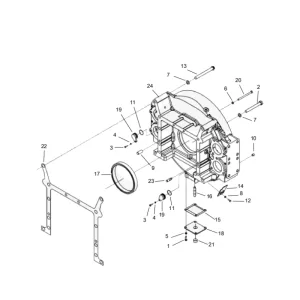

Q 3: What preparations should be made before installing the oil cooler?

A 3:①Confirm the accessory model (29564138) and the gearbox model (e.g. G. Alison 3000/4000 Series);②clean the oil port and pipeline of transmission (use a special cleaning agent to remove oil stains and impurities);③check the appearance of oil cooler (no deformation, no damage to the interface);④prepare the original sealant (model: Allison 1068127) and apply it to both sides of the interface gasket.

Q 4: Do I need to adjust the use of the oil cooler in different seasons?

A 4:①Winter (ambient temperature ≤ 0℃): If there is no temperature control valve, idle for 5-10 minutes after starting, and then run normally when the oil temperature rises above 40℃ to avoid excessive cold start flow resistance;②summer (ambient temperature ≥ 35 C): Clean the radiator dust regularly (once every 2 weeks). If the operation intensity is strong, install an auxiliary fan to improve heat dissipation efficiency.

Q 5:29564138 Oil cooler can replace other Allison oil coolers (for example. G. 29564137)?

A 5: It can not be replaced directly. The 29564138 and 29564137 have different cooling powers, interface sizes and suitable gearbox models (29564137 is used for Allison 2000 series and 29564138 is used for 3000/4000 series) Replacement may lead to insufficient heat dissipation or installation failure, so choose the appropriate accessories according to the gearbox model.

Q 6: What is the warranty period of the product and what does it cover?

A 6: The original factory warranty period is 12 months or 2000 working hours, whichever comes first. The warranty covers manufacturing defects, such as core breakage, seal leakage and temperature control valve failure, but does not include man-made damage (e.g. Impact, installation does not meet the specifications) or normal wear and tear (such as. Radiator dust jam).

Conclusion

In a word, the 29564138 Allison gearbox oil cooler assembly is a high-quality and reliable component, which provides many advantages for the planetary gearbox and planetary gear transmission gearbox planetary system. Its excellent performance in various aspects makes it an ideal choice for a wide range of applications in the commercial vehicle, construction machinery, and special vehicle industries.