Key Takeaways

· The XCMG XE 2000 excavator pipe clamp assembly 319001886 is a crucial mining excavator parts, ensuring the stability of hydraulic pipelines.

· It is made of military-grade materials, with intelligent shock-proof design, rapid installation and durable corrosion resistance.

· This product is suitable for harsh working environment such as open pit mines and large earthwork projects.

· Choosing the original manufacturer’s pipe clamp assembly is very important to avoid hydraulic failures caused by pipeline problems.

What is the clamp assembly 319001886 of XCMG XE 2000 excavator?

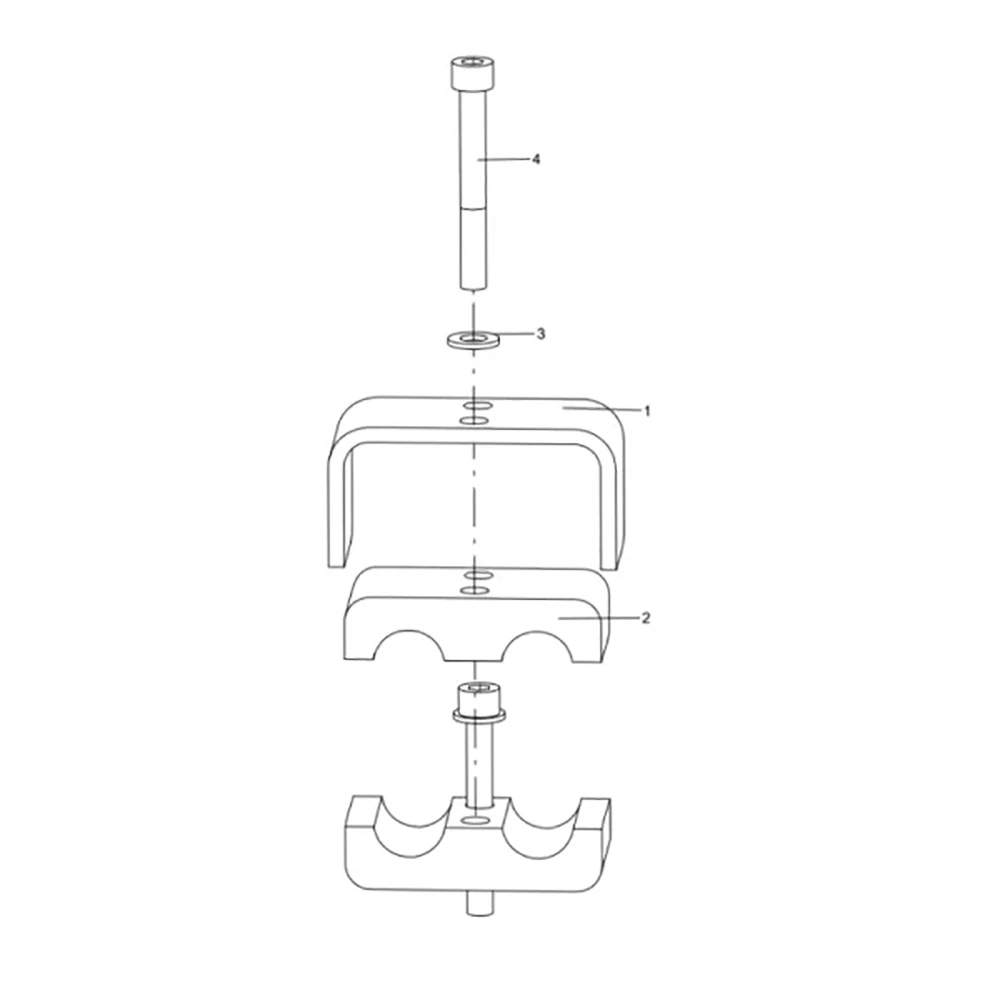

The XCMG XE 2000 excavator pipe clamp assembly 319001886 is a crucial component designed to secure hydraulic pipelines in mining excavators. It is made of high strength engineering materials, which can provide professional protection for your hydraulic system. This kind of component is specially designed to solve the pain points of pipeline looseness and accelerated wear of B 2B in harsh mining environment.

Unique advantage of the 319001886 pipe clamp assembly

The XCMG XE 2000 excavator pipe clamp assembly 319001886 is a crucial component designed to secure hydraulic pipelines in mining excavators.

In the mining environment, the subsequent shutdown and maintenance will lead to huge production losses. Industry analysis consistently lists hydraulic system failures as the main reason for unexpected shutdown of excavator. This is confirmed by a wider range of industry data, which emphasize the importance of maintenance in asset-intensive businesses. (Source:https://www.reliableplant.com/Read/30196/true-cost-downtime)

In addition, metal chips in the worn pipeline can enter the hydraulic system, which will cause catastrophic damage to sensitive and expensive components, such as pumps, valves and the planetary gearboxes. Planetary gearboxes rely on clean pressurized oil to lubricate and operate their planetary gear reduction system.

1. Enhanced Safety: Shielding Against Disaster

Hydraulic pipelines are the excavator’s power veins, carrying high – pressure fluid for boom, arm, and bucket movements. If they are not clamped correctly, they will be very fragile. Vibrations and shocks during operation can cause them to swing, rub or entangle. Over time, this will lead to wear and tear, weakening the pipeline. A small crack can turn into a big crack, releasing high-temperature and high-pressure liquid, which can burn operators and lead to sudden failure of the machine, such as uncontrolled movements or tipping over.

The pipe clamp assembly firmly holds the pipe in place. It can prevent them from moving and minimize wear and damage. This can ensure that the liquid remains inside, reducing the risk of pipeline rupture and hydraulic failures, and create a safer working environment.

2. Improving Efficiency: the smooth sailing of productivity

A stable hydraulic system is very important to the working efficiency of excavators. If the pipe is not well clamped and vibrated, it will lead to a surge in pressure. This makes the boom move unsteadily, too fast or too slow, making it difficult to dig or lift accurately.

With the pipe clamp assembly fixing the pipelines, the hydraulic system can run smoothly. Fluid flow is consistent, and pressure keeps the best. The actuator gets a stable power supply, so the boom, stick and bucket can move accurately and respond quickly. Operators can better control the excavator, complete the tasks more quickly and accurately, and improve the overall productivity.

3. Reduced Maintenance Costs: Long – Term Savings

The mining excavators spare parts is durable and corrosion resistant. It can handle the harsh environment, resisting wear, impact, and rust. This extends its service life, reducing the need for replacements. Less replacements means less downtime and lower maintenance costs, allowing excavator to run more continuously and providing better returns on investment.

Key component technology

· Metal Clamping Structure: Utilizes an “arc-shaped hoop+double-end bolt” symmetric design. The 8.8-grade high-strength bolts apply a pre-torque of 18-22n m, and the clamping force is amplified by leverage. A buffer gap of 1.5 mm was designed into the hoop to adapt to the thermal expansion of the pipeline.

· Composite rubber bushing (patent number: CN 202420401789.3): Double-layer structure of “external wear resistance and internal cushioning” is adopted. The outer layer is reinforced with 15% carbon fiber, and the inner layer is designed with honeycomb cushioning pad, achieving 85% shock absorption efficiency. The NBR compound is infused with 20% PTFE micro-powder, improving oil resistance by 40%.

· Quick-Install Mechanism (Patent: CN 202420467890.7): Features a “snap-fit positioning+bolt fastening” combo. The snap-fit allows quick alignment on the machine support, while a spring steel locking washer on the bolt prevents loosening under vibration.

Key Specifications

| Specification | Detail |

| Material | Special nylon composite, Q235B carbon steel |

| Temperature Range | -40℃ to 120℃ |

| Impact Resistance | Increased by 60% |

| Vibration Reduction | Up to 70% |

| Installation Time | ≤60 seconds (tool-free) |

| Corrosion Resistance | Special acid and alkali-resistant coating |

| Clamping Force | Rated ≥8kN,Ultimate: 12 kN |

| Vibration Test | 200 hours with ≤5% clamping force decay |

| Durability | 10000 hours (industry average: 6000 hours) |

| Environmental Adaptability | IP66 waterproof, Oil Resistance(ISO VG46, 168 hours no swelling) |

| Certifications | ISO 6405:2018, REACH, CE, ISO 9227:2017, JB/T 10391-2021 |

Common application

Industry 1: Open pit mining

In open pit mines, excavators are used for excavation and loading operations. The high-intensity vibrations and harsh environmental conditions make it very important to use reliable pipe clamp components to fix hydraulic pipes. The XCMG XE 2000 mining excavators spare parts 319001886 is well-suited for this application, providing stable and long-lasting protection for the hydraulic system.

Industry 2: Mining of metals

Metal mining usually involves the excavation of hard rock, which brings great pressure to the hydraulic system of excavators. The 85% vibration absorption of the clamp is very important to protect the lines that provide power for the digging function of the excavator and the rotary planetary gearbox, thus ensuring consistent strength and control.

Industry 3: Large-Scale Earthwork Projects

The clamp assembly 319001886 of XCMG XE 2000 excavator ensures the stability of the hydraulic pipelines, reducing the risk of shutdown, and improving the overall efficiency. The 85% vibration absorption of the clamp is very important to protect the lines that provide power for the digging function of the excavator and the rotary planetary gearbox, thus ensuring consistent strength and control.

How to Choose the Right XCMG XE 2000 Excavator Pipe Clamp Assembly 319001886?

Step 1: Identify your needs

Determine the specific requirements of your excavator, including the type of hydraulic pipelines, the working environment, and the expected vibration and impact. This will help you to choose the pipe clamp assembly that is suitable for your application.

Step 2: Confirm Specifications

Check the specifications of the XCMG XE 2000 excavator pipe clamp assembly 319001886, such as the material, clamping force, temperature range and corrosion resistance. Make sure these specifications meet or exceed the requirements of your excavator and working environment.

Step 3: Match the criteria

Verify whether the pipe clamp assembly meets the relevant industry standards and certifications, such as ISO 9001, CE and ISO 6405: 2018. This can ensure that the product meet the quality and safety requirements.

Step 4: Verify the Supplier

Choose a reputable supplier who provides the original manufacturer’s mining excavators spare parts. Check their customer comments, after-sales service and warranty policies to ensure the purchase is reliable.

Frequently Asked Questions

Q 1: The pipe clamp becomes loose after being used for a period of time, which causes the pipeline vibration to increase. How to solve the problem?

A: 1. Check the pre-tightening torque of bolts (it should reach 18-22n m; If it is not enough, tighten it with a torque wrench); 2. Check if the anti-loosening washer is deformed (if deformed, replace with an original spring steel washer); 3. If the rubber bushing is seriously worn (thickness is reduced by ≥ 2mm), the bushing assembly must be replaced at the same time.

Q 2: The rubber bushing will soften and fall off at high temperature. What can I do with this?

A: 1. Replace the high temperature resistant fluororubber bushing (original part model 319001886-01), which is suitable for the high temperature condition of 130℃; 2. Clean the inside of the pipe clamp of oil and dust, ensuring a tight fit between the bushing and the pipeline; 3. Enlarge the heat dissipation space of the pipe clamp to avoid direct contact with high-temperature parts.

Q 3: In high-humidity environments, the metal parts of the pipe clamp rust, affecting their appearance and tightness. How to prevent this from happening?

A: 1. Clean rust with rust remover, let it dry, and then spray with anti-rust paint (it is recommended to maintain this every 6 months); 2. Replace the aged pipe clamps with peeling powder coating to prevent further rust; 3. In coastal environments, apply anti-rust grease to the pipe clamp surface to enhance corrosion resistance.

Q 4: Will the expansion and cracking of the rubber bushing affect the use? How should I change it?

A: 1. The expanding and cracking bushing will reduce the buffering and fastening performance and must be replaced immediately; 2. Remove the bolt of the pipe clamp, take out the old bushing and remove the residual oil in the pipe clamp; 3. When installing the new bushing, make sure the direction is correct (the side with the buffer hole should face the pipeline) and tighten the bolts to the specified torque.

Q 5: After installation, the pipe clamp is not tightly attached to the pipeline, leaving gaps. How do you adjust this?

A: 1. Check the flatness of the pipe support (if the error is more than 0.3 mm, it needs to be leveled); 2. Replace it with a pipe clamp model matching the pipe diameter (ensure that the opening size matches the pipe diameter); 3. If the pipe clamp is deformed, please replace it with a new one so as to avoid insufficient clamping force caused by forced installation.

Conclusion

The XCMG XE 2000 excavator pipe clamp assembly 319001886 is a high-quality, durable, and efficient solution for securing hydraulic pipelines in mining and large-scale earthmoving projects. Its unique advantages, including military-grade materials, intelligent earthquake-proof design and rapid installation system, make it an ideal choice for operators seeking to improve safety, efficiency and durability. By choosing the original manufacturer’s mining excavators spare parts, you can avoid hydraulic failures caused by pipeline problems and ensure that your excavator runs continuously and safely.