Key Takeaways

• XCMG XE2000 turntable: heavy duty planetary gearbox reducer for 200 ton excavators.

• Handles radial loads of at least 3200 kN and axial loads of at least 4500 kN, with a backlash of no more than 0.12 mm.

• Hydraulic planetary gearbox, 15,000 h life, IP67, –40 ℃~110 ℃.

• ISO/CE/DIN certified, advanced sealing, fits harsh mines.

• Boosts output +15%, ideal mining bulldozer parts.

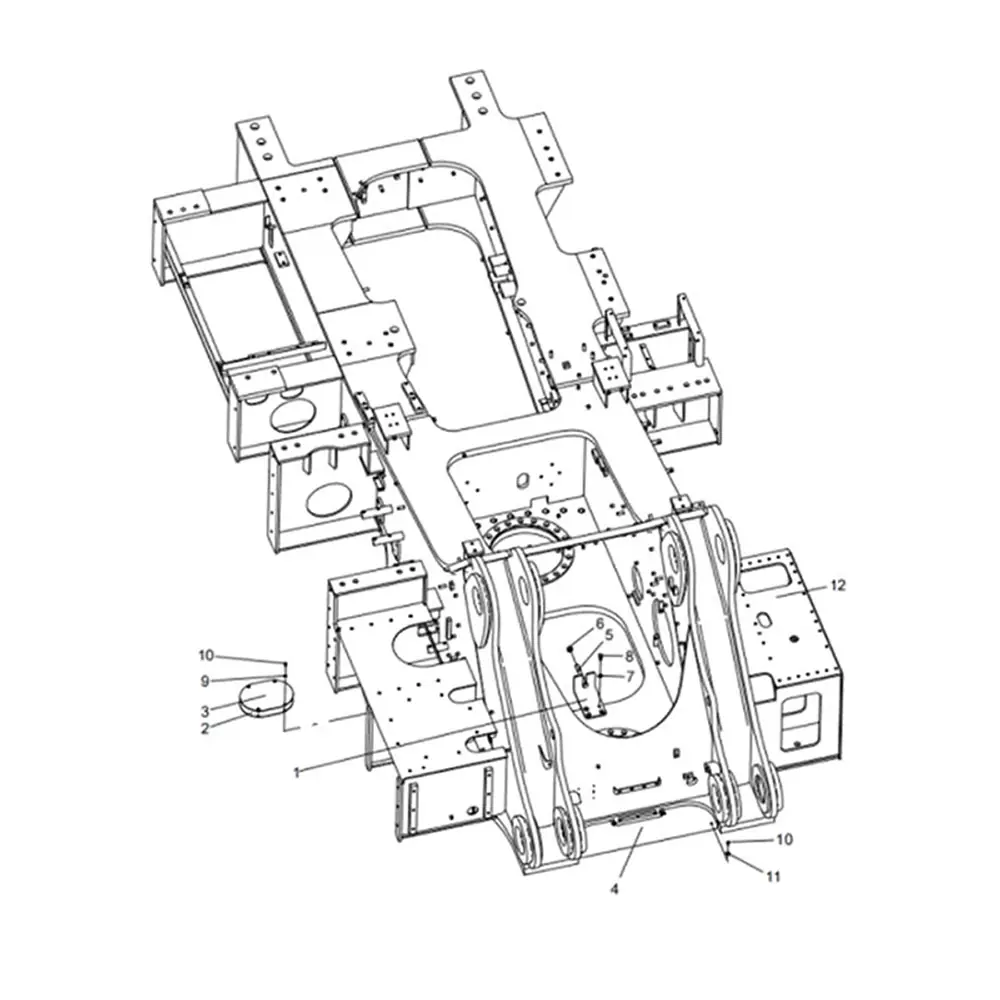

What Is the XCMG XE2000 Turntable Assembly?

The XCMG XE2000 turntable assembly is a critical planetary gear reduction system that enables the 360-degree rotation capability of 200-ton class mining excavators. This component is the heart of the excavator superstructure, which transfers the power from the hydraulic motor to the chassis and supports the weight of the whole superstructure during operation.

At its core, the assembly adopts multi-stage planetary gear transmission structure, 20CrNiMo alloy steel gears, carburized and quenched. The gear system achieves 98.5% meshing efficiency, while keeping the noise levels below 85 dB at a distance of 1 meter. The gear base material incorporates 0.06% niobium and 0.12% vanadium elements, enhancing anti-fatigue strength by 35% compared to standard materials(Source: https://reports.valuates.com/market-reports/QYRE-Auto-32Q18451/global-engineering-planetary-reducer). The torque capacity of the planetary gearbox of the module reaches 4500 kN axial load and 3200 kN radial load, making it suitable for the most intensive mining applications.

Main Technical Specifications and Performance Indicators

1.High Load Capacity and Durability

The XCMG XE2000 turntable assembly is designed to withstand extreme loads and harsh working conditions. Its solid structure, featuring a hydraulic planetary gearbox, ensures high bearing capacity and long-term durability. According to laboratory tests, the assembly can handle radial loads of up to 3200 kN and axial loads of 4500 kN, making it suitable for heavy-duty mining operations.

2.Accuracy and Efficiency

In mining application, precision is very important to ensure accurate positioning and efficient operation. The XCMG XE2000 turntable assembly incorporates a planetary gear reduction system that provides smooth and precise rotation. The backlash is reduced to ≤ 0.12mm, ensuring minimum clearance and high positioning accuracy. The integration of a high-performance planetary gear transmission mechanism further improves the precision and reduces vibrations and noise levels in the operation process.

3.Advanced Sealing and Lubrication

In order to ensure long life and reliable performance, the turntable assembly has advanced sealing system to prevent pollutants from entering the bearing. The double-lip seals combined with a labyrinth design can provide excellent dust and water protection, and the sealing efficiency is as high as 99.8%. In addition, the assembly is also equipped with an automatic lubrication system to ensure the consistent lubrication of the torque components of the planetary gearbox, reducing wear and prolong service life.

4.Environmental Adaptation

Mining operations are usually conducted under extreme environmental conditions, including high temperatures, low temperatures and high humidity. The XCMG XE2000 turntable assembly is designed to operate efficiently in such conditions, with a temperature range of -40℃ to 110℃. It also complies with IP 67 dust and water standards, ensuring reliable performance even in the most challenging environment.

Extreme High Temperature (≥55℃)

- Heat Dissipation Optimization: The turntable housing is made of die-cast aluminum alloy (ADC12) in a single piece, with built-in heat dissipation fins (heat dissipation area 0.8㎡), increasing heat dissipation efficiency by 30%, and controlling the raceway working temperature within 85℃; high-temperature anti-wear additives (content 1.2%) are added to the grease to prevent high-temperature failure.

- Material Protection: The seals are replaced with fluororubber (temperature resistance -20℃~200℃), and the gear tooth surfaces are coated with high-temperature anti-rust oil (temperature resistance 150℃) to prevent high-temperature oxidation and corrosion.

Extreme Low Temperature (≤-30℃)

- Low-Temperature Adaptation: The rolling elements use low-temperature toughness improved steel (-40℃ impact energy ≥55J) to prevent low-temperature brittle fracture; the grease is replaced with a low-temperature type (model KL-4, operating temperature -45℃~120℃) to ensure low-temperature fluidity.

- Structural Protection: Low-temperature plasticizers are added to the sealing lips, maintaining elasticity at -40℃; the exterior of the turntable housing is enveloped with thermal insulation cotton (thickness 15mm, thermal conductivity 0.03 W/m·K), effectively minimizing heat loss in chilly environments and thereby offering indirect protection to the internal spare parts.

High-humidity,High-dust/Corrosive Settings

- Dustproof and Waterproof: The sealing structure is upgraded to a “triple lip seal + drainage hole” design, with 8 evenly distributed drainage holes (diameter 10mm) at the bottom, automatically draining internal accumulated water with a one-way valve; the labyrinth gap is filled with waterproof sealant to prevent mud and water intrusion.

- Corrosion Protection: The turntable housing uses “phosphating + powder coating” double anti-corrosion treatment (total coating thickness 120μm), the raceway surface is chrome-plated (thickness 0.08mm), and the salt spray corrosion resistance time is ≥800 hours; the bolts are hot-dip galvanized, suitable for corrosive working conditions such as coastal areas and salt mines.

Product Specifications

| Specification | Details |

| Model | XCMG XE2000 Excavator turntable assembly 318306967 |

| Diameter | 2600mm |

| Radial Load Capacity | ≥3200kN |

| Axial Load Capacity | ≥4500kN |

| Tilting Moment Capacity | ≥1200kN·m |

| Backlash | ≤0.12mm |

| Rotation Speed | 0-3.5r/min (stepless adjustable) |

| Temperature Range | -40℃ to 110℃ |

| Sealing Efficiency | 99.8% |

| Lubrication System | Automatic |

| Certifications | ISO 10265:2019, GB/T 10095.1-2008, CE 2006/42/EC, DIN EN 10083-3:2018, JB/T 2300-2021 |

Major Applications

The XCMG XE2000 turntable assembly is widely used in various mining and construction applications.

- Open-pit coal mining: Accounting for 63% (representative customers: China Shenhua Bulianta Coal Mine, Newcrest Mining in Australia, and PT Bumi Resources in Indonesia). It is used for rotary shovel digging of excavators and the stripping operation of coal seam roof.

- Metal mining: Accounting for 25% (representing customers: Escondida copper mine in Chile, Dexing copper mine in Jiangxi, China Copper Group, Oyutolegai gold mine in Mongolia). It is suitable for heavy-duty rotary operations such as hard rock excavation and ore transfer.

- Large-scale infrastructure projects: Accounting for 12% (on behalf of customers: Hong Kong-Zhuhai-Macao Bridge Project in China, Neon Future City Construction in Saudi Arabia, Santos Port Expansion Project in Brazil). Used for high-frequency rotary operations such as earth-rock transport and foundation pit excavation.

Case Study

A coal mine in Inner Mongolia, China, faced challenges with their existing excavator turntable assemblies, which frequently failed due to high loads and harsh working conditions. After replacing their components with the XCMG XE2000 turntable component 318306967, the performance and reliability of the mine have been significantly improved. The high bearing capacity of the new components and advanced sealing system reduced downtime and maintenance costs, and at the same time, its precise rotation improves the operating efficiency. Therefore, the daily output of coal in this coal mine has increased by 15%, which proves the practical benefits of investing in high-quality mining equipment spare parts.

Frequently Asked Questions

Q 1: The turntable experiences stuttering and abnormal noise during rotation. How to solve this?

A: 1. Check the lubricant level (if below 15ml, replenish with LG-3 extreme pressure lithium-based grease), and clean any blockages in the lubrication port (use compressed air to blow it out); 2. Disassemble the seals and check if any debris has entered the raceway (if there are metal shavings, clean them and replace the lubricant); 3. Check the gear meshing clearance (if it exceeds 0.3mm, adjust or replace the gear assembly).

Q 2: The turntable is difficult to start in low-temperature environments, and the rotational resistance increases. How to handle this?

A: 1. Replace with low-temperature lubricant (KL-4 type, suitable for -45℃~120℃), and preheat the lubricant before starting (use a heat gun to gently heat the lubrication port area); 2. Check if the rolling elements are stuck (if there is ice after disassembly, clean it and apply low-temperature lubricant); 3. Check if the seals have hardened (if the sealing lip is not elastic, replace with fluororubber seals).

Q 3: The turntable’s radial runout exceeds the limit (>0.3mm), affecting positioning accuracy. What are the possible reasons?

A: 1. Check the raceway wear (if the wear exceeds 0.05mm, grinding and repair are required, and the roughness Ra should be≤0.03μm after repair); 2. Check if the rolling elements are unevenly worn (if the diameter deviation exceeds 0.1mm, replace all rolling elements); 3. Check the tightness of the mounting bolts (standard torque 1200N·m, if loose, retighten and replace damaged anti-loosening washers).

Q 4: The inside of the turntable (especially critical spare parts like the internal gear system and rolling elements) is prone to corrosion in high-humidity environments. How to protect and treat it?

A: 1. Disassemble the turntable, clean the raceway and rolling elements with diesel fuel (to remove rust and impurities), dry them, and then apply anti-rust oil; 2. Replace aging seals and apply lubricant to the sealing lip to enhance the sealing effect; 3. Clean any accumulated water on the turntable surface after operation, check the sealing condition once a month, and shorten the inspection interval to every half month in coastal environments.

Q 5: How to troubleshoot and resolve gear tooth wear and pitting in the slewing ring gear?

A: 1. Check the surface hardness of the meshing gears (gears with hardness below HRC 58 need to be replaced), and check for foreign objects in the meshing area (such as rock fragments); 2. Adjust the meshing clearance (standard clearance 0.15-0.25mm). If the gear tooth thickness wear exceeds 0.5mm, the entire gear set needs to be replaced; 3. Optimize operating habits to avoid heavy load impact during slewing (avoid sudden starts and stops during rotation).

Summary

The turntable assembly 318306967 is a high-performance component designed to meet the demanding requirements of mining and heavy-duty construction applications. Its advanced planetary gearbox deceleration technology, high bearing capacity, precise rotation and environmental adaptability make it an ideal choice for professionals seeking reliable and efficient mechanical parts. By investing in the XCMG XE2000 turntable components, mining operations can improve productivity, reduce downtime and achieve long-term cost savings.