In the demanding mining industry, the normal operation time and efficiency of the equipment are very important. A single component with poor performance can lead to significant operation delay and costs increase. For owners and maintenance managers of XCMG’s powerful XE 2000 excavator, one critical component stands out for its impact on hydraulic control: the quadruple solenoid assembly. Specifically, the XCMG XE 2000 Excavator quadruple solenoid assembly 318307914 is a precision-engineered spare part designed to meet the rigorous demands of heavy-duty mining applications. This paper provides a comprehensive data-driven guide to this important component, explaining what it is, its unique advantages, specifications and how it can ensure your excavator to run at the best performance.

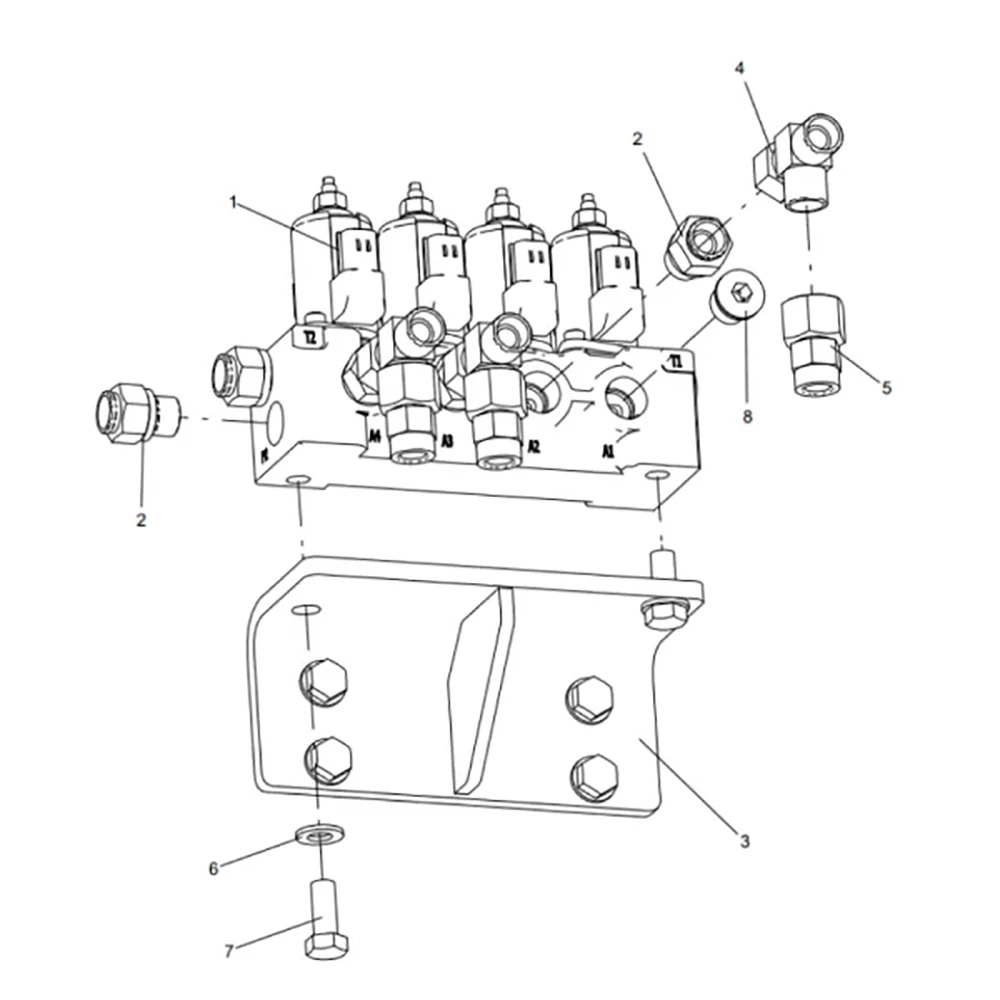

What is the quadrupole electromagnetic assembly 318307914 of XCMG XE 2000 excavator?

At its core, a solenoid assembly is an electromechanical device, which converts electrical energy into linear mechanical motion. In a hydraulic system, it plays the role of control valve. The “quadruple” sign means that this special component integrates four independent solenoid valves into a compact device. XCMG XE 2000 excavator four-pole solenoid valve assembly 318307914 is a real spare part, which aims to precisely control the hydraulic fluid flow and direction of various actuators (such as boom, bucket, bucket and rotary function) on the XE 2000 mining excavator. Its main function is to receive low-power electrical signals from the excavator control system and convert it into high-power hydraulic actions. This direct control of strong hydraulic pressure makes accurate and sensitive movement the basis of efficient excavation, lifting and loading cycles in mining operations. Sourcing authentic XCMG Mining Excavators Spare Parts, like this solenoid assembly, is crucial for maintaining original equipment performance and reliability.

Technical Specifications and Key Performance Data

The XCMG Mining Excavators Spare Part is defined by a set of rigorous, laboratory-tested performance metrics that set it apart from generic alternatives. These quantifiable results highlight its applicability in extreme mining conditions.

· Response Speed: laboratory tests confirm that the response time of single valve drive is ≤ 0.08 seconds. For synchronous control of four valves, the response error is less than or equal to 0.02 seconds. This is approximately 33% faster than the industry average of 0.12 seconds for similar-sized products, directly translating to smoother, more coordinated excavator movements

· Rated pressure and durability: the rated working pressure of the assembly is 35 MPa. In extreme pressure test, there is no leakage after being subjected to 50 MPa for 10 minutes. The valve operates in the stable working pressure fluctuation range of 0.5 MPa. The life test shows that the device can withstand more than 1 million switching cycles, the change of coil resistance is minimal (≤ 5%), and the mean time between failures (MTBF) reaches 8,000 hours, exceeding the industry average of 6,000 hours.

· Environmental Resilience: designed for global mining sites, it operates reliably within a temperature range of -40 ° c to 120 ° c. It also has the protection level of IP 6K 9K, providing excellent protection against high-pressure water jet and dust intrusion, which is a key feature for mining environment.

Unique advantages and core technologies

What makes this specific quadruple solenoid assembly the preferred choice for the XCMG XE 2000? These advantages come from its advanced design and material science.

· Enhanced electromagnetic Coil: made of high-grade copper wire, generating a strong magnetic field (≥ 0.5 t) to drive the valve core. It includes a built-in PT 1000 temperature sensor, which is used to automatically turn off the protection when the temperatures exceeds 120 C. The coil frame is made of high-temperature PA 66+30% glass fiber material, and the insulation is polyimide film, which conforms to relevant safety standards (Source:https://www.shopulstandards.com/Catalog.aspx)

· Precision Valve Spool and sleeve: the spool is made from hardened 45 # steel with a chrome-plated surface (Ra ≤ 0.02’m roughness), moving within a honed valve sleeve with an IT 5-grade tolerance. This pairing minimizes internal leakage (static leakage ≤ 0.1 ml/min at 30 MPa) and reduces wear, thus ensuring long-term accuracy. PWM (pulse width modulation) compatible design allows accurate flow control with an accuracy of 2%.

· Robust Sealing System: the assembly employs a dual-seal groove design with a backup ring to prevent extrusion under high pressure. It uses special seals: static seals use nitrile rubber (NBR), dynamic seals use wear-resistant polyurethane. Under normal working conditions, this configuration can extend the sealing life to about 5,000 hours.

The main Applications and industry impact

The XCMG XE 2000 Excavator quadruple solenoid assembly is critical in sectors where hydraulic precision and reliability under stress are non-negotiable. Data shows that its main application are broken down as follows:

1.Open pit coal mining (approx 63%)

This is the leading application. In high-cycle coal loading operations, the quick response and durability of the quadruple solenoid valve assembly ensure the effective control of the bucket and stick, thus maximizing the amount of material moved per hour. A case study from a large coal mine in China shows that the cycle time of each excavation is reduced by 4 seconds and the monthly output is increased by 16.7% after replacing a standard valve with the 318307914 components.

2.Metal ore mining (approx 24%)

In copper, iron and other metal mines, excavators have to face hard abrasive materials. The high-pressure resistance (35 MPa) and solid structure of the assembly provide the stable and powerful hydraulic control for crushing and loading dense ore.

3.Large-Scale Infrastructure Projects (approx 13%)

For major excavation work in rail, road, and dam construction, the precision control offered by this spare part enables smooth, accurate movement for grading and trenching, reducing rework.

Coping with extreme working conditions

Mining excavators can not be operated in controlled environment. The XCMG Mining Excavators Spare Part incorporates specific design features to handle extremes.

· Extreme high temperature (≥ 60 degrees Celsius): the aluminum alloy valve body has integrated fins. High temperature fluorocarbon sealing and heat conducting materials can prevent failure.

· Extreme cold (≤-30 degrees Celsius): the module includes a low-temperature start-up auxiliary. A built-in PTC heater is started below-25 C, and the internal components are heated to the working temperature within a few minutes. Specially formulated low-temperature grease can prevent the valve core from getting stuck.

· High dust/Moisture: the IP 6K 9K certified housing, combined with sealed connectors and weather-resistant sealant at joints, provides exceptional protection against dust and water ingress, common in mining and quarry sites.

Comparison with common substitutes

When considering XCMG Mining Excavators Spare Parts, it’s useful to understand how genuine parts compare. The table below highlights key differences between the genuine XCMG quadruple solenoid assembly and typical aftermarket alternatives.

| Feature | XCMG 318307914 Assembly | Typical Aftermarket Alternative | Impact |

| Response Time | ≤0.08 seconds | 0.12 – 0.15 seconds | Smoother, faster machine cycles. |

| Seal Material & Design | Specialized NBR/PU, dual-groove design. | Standard rubber seals, single-groove. | Longer life, less leakage, lower long-term cost. |

| Protection Rating | IP6K9K (Dust-tight, high-pressure water jet resistant). | Typically IP67 or lower | Better reliability in wet, dusty mine environments. |

| MTBF (Estimated) | 8,000 hours | 4,000 – 6,000 hours | Longer service intervals, reduced unexpected downtime. |

Frequently Asked Questions

Q 1: The action of solenoid valve is delayed, resulting in a slow response of the hydraulic system. How to solve this?

A : 1. Check the supply voltage of the coil (the standard is 24V 10%). If the voltage is insufficient, you need to repair the power module; 2. Remove the valve core and remove impurities in the oil circuit (it is recommended to replace the hydraulic oil filter element every 2000 hours); 3. If the valve core is worn (the radial runout is greater than 0.02 mm), it is necessary to replace the valve core assembly.

Q 2: In high temperature environment, the electromagnetic valve of the excavator often triggers over-temperature protection. What should I do?

A : 1. Clean the dust on the radiator of the valve body (blow with compressed air once a week); 2. Check whether the PTC heater is not started normally (if it is still starts when the temperature is higher than 50℃, the temperature sensor needs to be replaced); 3. Replace the fluororubber seals and high temperature grease to improve the high temperature resistance.

Q 3 : The hydraulic oil is leaking seriously. What are the possible reasons and countermeasures?

A : 1.Check whether the seals are aged (if the hardness is greater than 80 Shore A, they need to be replaced); 2. Check the fit clearance between the valve core and the valve sleeve (if it is greater than 0.015 mm, the valve sleeve needs to be repaired or replaced by grinding); 3. Check whether the working pressure exceeds the rated value (if it is greater than 35 MPa, the pressure of the safety valve needs to be adjusted).

Q 4: The solenoid valve can not be started in low temperature environment. How to eliminate the fault?

A : 1. Check the working state of the PTC heater on the excavator(if the temperature does not rise within 3 minutes after power on, you need to replace the heater); 2. Replace the low-temperature lubricating grease (KL-4 model) and clear any ice inside the valve spool (low – temperature baking with a hot air gun can be used); 3. Measure the resistance of the coil (the standard is 15-18Ω. If the resistance is not normal, the coil needs to be replaced).

Q 5: The synchronous control error of the four-way valve is large (greater than 0.05 s), affecting the operational accuracy. How to solve this?

A : 1. Calibrate the PWM control signals (special debugging equipment is needed to ensure the error of the four groups of signals is less than or equal to 0.01 s); 2. Check the consistency of the spool stroke (if the difference is greater than 0.1 mm, you need to adjust the spool limit); 3. Replace the aging spring assemblies (if the spring force decays by more than 10%, it will lead to inconsistent reset).

Conclusion: An Investment in Precision and Reliability

In the high-stakes environment of mining, equipment decisions are business decisions. The four-pole solenoid assembly 318307914 of XCMG XE 2000 excavator is not only a spare part; It is a performance-critical component engineered to restore and even enhance the original capabilities of a major capital asset. Its proven speed, solid structure suitable for extreme environment and excellent durability directly confront the two biggest costs in mining: downtime and inefficiency. Choosing genuine, high-performance XCMG Mining Excavators Spare Parts like this quadruple solenoid assembly is a strategic investment. It ensures that every action of the XE 2000 excavator is as fast, powerful and accurate as when debugging, thus ensuring productivity and maximizing the return on investment of heavy equipment.