Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318301034 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Steel Pipe Assembly (Part No. 318301034): Rigid Transmission Framework Supporting Efficient Operation

In high-intensity operation scenarios such as large-scale mining and heavy engineering construction, the XCMG XE2000 excavator, with its powerful performance, has become a core piece of construction equipment. The steel pipe assembly (part no. 318301034), as the rigid framework of the machine’s fluid transmission system, bears the heavy responsibility of directional delivery of key media such as hydraulic oil and coolant, providing solid support for the XE2000’s continuous and stable operation under complex working conditions.

Precise Adaptation, Fitting the Overall System Layout

The XCMG XE2000 excavator has a precise and complex structure, and each system has extremely high requirements for the pressure, flow rate, and pipeline routing of fluid transmission. The steel pipe assembly (part number 318301034) is specifically designed for the XE2000’s overall parameters and piping layout, precisely matching the high-pressure working environment of the hydraulic system (maximum working pressure up to 35MPa) and the media transmission standards of cooling and lubrication systems. Whether connecting core components such as the hydraulic pump and main valve, or building coolant delivery channels in the cooling circuit, this steel pipe assembly perfectly fits all components of the machine. Through optimized piping design, it ensures efficient fluid flow within the dense equipment structure, providing reliable rigid connections for the XE2000’s powerful output and the coordinated operation of its various mechanisms.

High-strength material withstands harsh working conditions

The mining environment is harsh, and the steel pipe assembly must withstand multiple tests over a long period, including high-frequency vibration, heavy object impacts, and dust erosion. The XCMG XE2000 steel pipe assembly (part number 318301034) is manufactured using high-strength seamless steel pipes. Through precision forging and heat treatment, it possesses extremely high tensile and compressive strength, with a yield strength exceeding 450MPa, effectively resisting external impacts and system pressure fluctuations during operation. The steel pipe surface undergoes multiple anti-corrosion treatments, including phosphating, galvanizing, and high-temperature painting, forming a tight protective layer that effectively resists rust and chemical corrosion in humid and dusty environments. Even under extreme working conditions, it maintains structural stability for a long time, preventing media leakage caused by pipeline damage.

Rigid support ensures stable and efficient transmission

Unlike flexible hoses, the steel pipe assembly (part number 318301034) possesses excellent rigidity and structural stability. During operation of the XCMG XE2000 excavator, vibrations from the machine body and working devices continuously affect the piping system. This steel pipe assembly, with its robust rigid structure, maintains the fixed direction and connection precision of the piping, preventing blockages or loosening of joints due to deformation. Simultaneously, its precise pipe diameter design and inner wall polishing treatment (roughness Ra≤0.8μm) effectively reduce frictional resistance during fluid transmission, minimizing pressure loss and ensuring a stable flow and pressure of hydraulic oil, coolant, and other media to all required components, thus improving the overall system’s operating efficiency.

Precision machining ensures reliable and durable connections

XCMG maintains strict control over the manufacturing process of core components. The steel pipe assembly (part number 318301034) undergoes multiple precision machining processes during production. The cutting, bending, and welding of steel pipes are all carried out using automated CNC equipment, ensuring dimensional accuracy and geometric tolerances are controlled within ±0.1mm. The flatness and sealing of pipe interfaces are tested by professional helium testing equipment, and the mating clearance with joints is controlled within 0.05mm. Finished steel pipe assemblies also undergo rigorous testing, including a pressure resistance test at 1.5 times the working pressure and a 24-hour airtightness test, to ensure no leakage or deformation under high-pressure conditions. This precise processing technology and strict quality control process give the steel pipe assembly an exceptionally long service life, significantly reducing equipment maintenance and replacement frequency, minimizing downtime, and lowering overall operating costs for users.

Choosing the XCMG XE2000 excavator steel pipe assembly (part number 318301034) means choosing stable and reliable fluid transmission and durable operational support. As an important component of XCMG’s high-quality parts system, it will provide your XE2000 excavator with continuous rigid power transmission during high-intensity operations, facilitating efficient project progress. For more information on product specifications, sourcing channels, or technical support, please feel free to contact us. Let our professional accessories safeguard your equipment.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

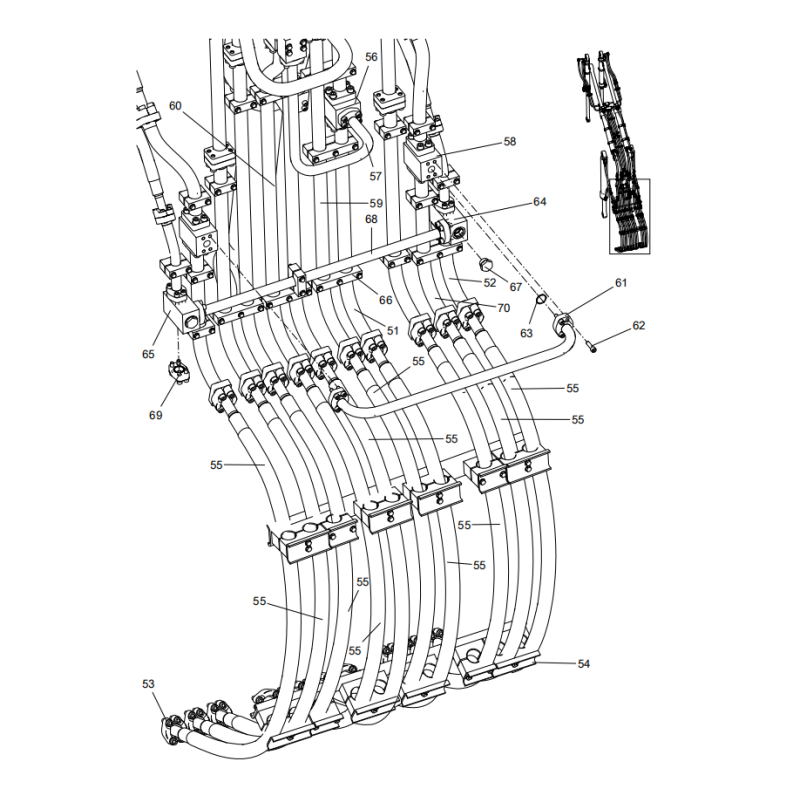

318307969 working device piping

51 318301035 3 STEEL PIPE ASSEMBLY

52 318306772 1 STEEL PIPE ASSEMBLY

53 803418697 32 FLANGE ASSEMBLY

54 318301038 2 PIPE CLAMP ASSEMBLY

55 804414280 10 HOSE ASS’Y

56 318301050 2 BLOCK

57 318301029 1 STEEL PIPE ASSEMBLY

58 318301043 2 BLOCK

59 318301036 3 STEEL PIPE ASSEMBLY

60 318301037 1 STEEL PIPE ASSEMBLY

61 318301039 1 STEEL PIPE ASSEMBLY

62 805139922 48 SCREW M16×55 GB/T70.1-2008

63 803130024 13 ORING 47.22×3.53 AS568

64 318306771 1 BLOCK

65 318301044 1 BLOCK

66 318300996 10 PIPE CLAMP ASSEMBLY

67 803438356 3 PLUG

68 318301030 1 STEEL PIPE ASSEMBLY

69 318503808 1 BLIND FLANGE ASSEMBLY

70 318301034 2 STEEL PIPE ASSEMBLY

##