Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803438356 plug XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Plug (Part No. 803438356): Precision Sealing Guarantee for Efficient Operation

In high-intensity operation scenarios such as large-scale mining and heavy engineering construction, the XCMG XE2000 excavator, with its powerful performance, has become a core piece of construction equipment. The plug (part no. 803438356), as a precision sealing component of the machine’s fluid system, bears the heavy responsibility of sealing pipeline ports and cavity interfaces. It provides a solid guarantee against media leakage in key components such as the XE2000’s hydraulic and lubrication systems, making it a “small but crucial” core component ensuring stable equipment operation.

Precise Fit, Meeting System Sealing Requirements

The XCMG XE2000 excavator’s hydraulic and lubrication systems have complex pipeline layouts, placing extremely high demands on the dimensional accuracy and matching degree of sealing components. The plug (part number 803438356) is specifically designed and manufactured to meet the piping interface parameters and sealing standards of the XE2000, precisely matching the thread specifications, dimensional tolerances, and sealing pressure requirements of the corresponding interfaces. Whether sealing pre-reserved interfaces in hydraulic pipelines or process holes in sealing cavities, this plug perfectly fits the interface, achieving a seamless connection through precise dimensional control. This ensures no loosening or leakage under high-pressure conditions (maximum pressure up to 35MPa), providing reliable sealing support for the closed-loop circulation of media in various systems.

Superior Material, Resistant to Harsh Working Conditions

In mining environments, the plug must withstand multiple challenges, including long-term exposure to high-pressure media, alternating high and low temperatures, and corrosion from dust and oil. The XCMG XE2000 plug (part number 803438356) is made of high-strength alloy steel or special engineering plastics. The metal material undergoes precision forging and surface hardening treatment, possessing excellent compressive strength and wear resistance, effectively resisting deformation caused by media pressure. The non-metallic material uses oil-resistant and aging-resistant special materials, maintaining stable physical properties within a temperature range of -30℃ to 120℃. Simultaneously, the sealing surface is finely machined or equipped with high-quality sealing gaskets, further enhancing sealing performance, resisting long-term corrosion from hydraulic oil, lubricating oil, and other media, and extending service life.

Precision structure ensures reliable sealing performance

The sealing effect of the plug directly depends on the precision of its structural design. The XCMG XE2000 plug (part number 803438356) features an optimized sealing structure design. The threaded portion achieves a precision of 6g or higher, with complete tooth profiles and a smooth surface, ensuring a tight fit with the interface thread and forming the first line of defense for sealing. The end sealing surface undergoes high-precision grinding, with a flatness error controlled within 0.01mm/m, ensuring a tight fit with the interface sealing surface and forming a second line of defense with the sealing gasket. For plugs in high-pressure areas, a conical or spherical sealing structure is used, achieving a self-tightening seal through pre-tightening force. This maintains a stable sealing effect even under vibration conditions, eliminating the risk of media leakage.

Strict quality control ensures long-term stable operation

XCMG maintains strict quality control over core components throughout the entire production process. The plug (part number 803438356) undergoes rigorous testing from raw material selection to finished product delivery. Raw materials undergo multiple inspections, including component analysis and mechanical performance testing, to ensure material quality. During production, key indicators such as thread precision and sealing surface smoothness are 100% inspected using precision measuring tools. Finished plugs also undergo rigorous testing, including pressure resistance, sealing performance, and vibration testing, to ensure no leakage or loosening under simulated operating conditions. This comprehensive quality control system gives the plug extremely high reliability, effectively preventing media leakage and system pressure drops caused by seal failure, reducing equipment downtime and maintenance time, and lowering overall user costs.

Choosing the XCMG XE2000 excavator plug (part number 803438356) means choosing precise and reliable sealing and continuous, efficient equipment operation. As an important component of XCMG’s high-quality parts system, it is small in size but plays a crucial role, providing a solid sealing defense for your XE2000 excavator during high-intensity operations and facilitating efficient project progress. For more product parameters, procurement channels, or technical support, please feel free to contact us. Let professional parts safeguard your equipment.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

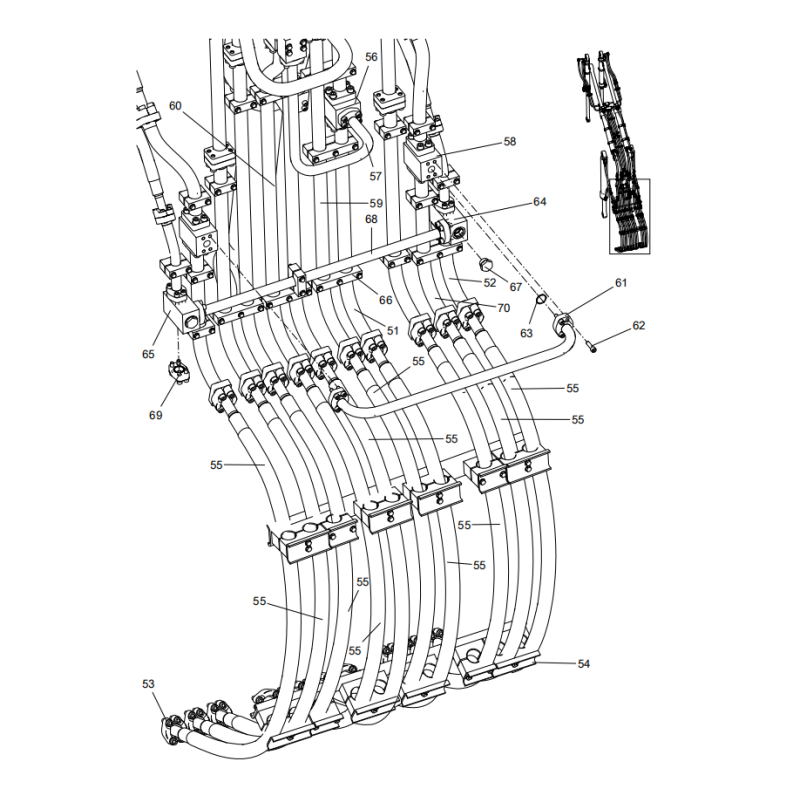

318307969 working device piping

51 318301035 3 STEEL PIPE ASSEMBLY

52 318306772 1 STEEL PIPE ASSEMBLY

53 803418697 32 FLANGE ASSEMBLY

54 318301038 2 PIPE CLAMP ASSEMBLY

55 804414280 10 HOSE ASS’Y

56 318301050 2 BLOCK

57 318301029 1 STEEL PIPE ASSEMBLY

58 318301043 2 BLOCK

59 318301036 3 STEEL PIPE ASSEMBLY

60 318301037 1 STEEL PIPE ASSEMBLY

61 318301039 1 STEEL PIPE ASSEMBLY

62 805139922 48 SCREW M16×55 GB/T70.1-2008

63 803130024 13 ORING 47.22×3.53 AS568

64 318306771 1 BLOCK

65 318301044 1 BLOCK

66 318300996 10 PIPE CLAMP ASSEMBLY

67 803438356 3 PLUG

68 318301030 1 STEEL PIPE ASSEMBLY

69 318503808 1 BLIND FLANGE ASSEMBLY

70 318301034 2 STEEL PIPE ASSEMBLY

##