Key Takeaways:

Choosing the best bucket for your mining excavator will directly affect the productivity and profit. XCMG XE2000 Bucket (Part No.318307308) represents excellent engineering technology of excavator spare parts. The wear resistance of its NM 500 steel structure is 2.3 times that of the standard materials; Patented designs makes the hard rock productivity exceeding 350 m/h; The recorded tests show that compared with competitors, the annual cost is lower and the reliability is higher; It conforms to the ISO 10265: 2019 standard, and is an ideal choice for coal mines, metal mines and large-scale earthworks.

What is XE2000 excavator bucket 318307308?

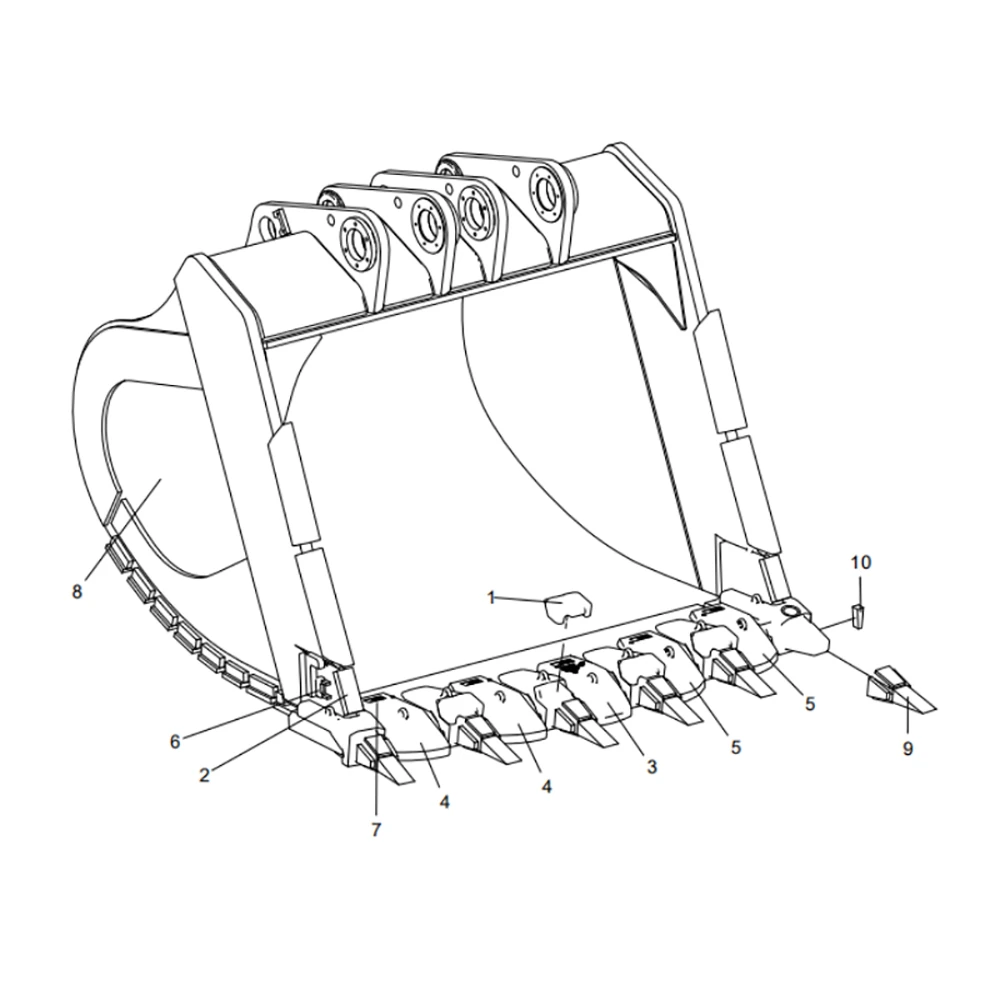

XCMG XE2000 excavator bucket 318307308 is a heavy-duty front-end accessory, which is classified as spare parts for mining excavators. It is specially customized for XE2000 hydraulic excavators of XCMG Group, and is used to deal with high-density materials such as granite, basalt and coal.

In the industry, this product is also commonly called “heavy-duty wear-resistant excavator bucket” or “NM 500 steel mining bucket”, which are all from China Construction Machinery Industry Association (http://www.cncma.org/)As a key member of excavators spare parts, its design adheres to the principle of balancing structural strength and operational flexibility to ensure that it can adapt to various working conditions without damaging its performance.

Why is the bucket of XCMG XE2000 excavator very important in mining Industry?

If there is no high-performance excavator bucket, mining operations will face three major risks.

· First, frequent replacement of worn buckets will reduce effective working time, and ordinary buckets needs to be replaced every 600 hours in granite mining;

· Secondly, low loading efficiency leads to the reduction of daily output, because the standard buckets can only reach 280-300 me/h in hard rock conditions;

· Thirdly, structural failures of buckets may lead to safety accidents, such as tooth loss or bucket deformation in the operation process.

Using the XCMG XE2000 excavator bucket 318307308 as a core part of excavators spare parts has brought three core benefits to enterprises.

· First of all, its high wear resistance extends the service life of the bucket under granite conditions to 800 hours, which is 33% higher than the industry average, greatly reducing replacement frequency.

· Secondly, the standard bucket capacity of 12 me and stable circulation efficiency of 32-35 cycles per hour make the working efficiency ≥ 350 me/h, and the daily output increases by 16.7% compared with the ordinary buckets.

· Thirdly, its structural stability ensures safe operation under overload conditions-bearing an instantaneous impact force of 420 kN, and the deformation is less than or equal to 1.5 mm-and eliminates the potential safety hazards caused by the failure of the bucket failure.

Features of XCMG XE2000 Excavator Bucket 318307308

| Specification Category | XCMG XE2000 Bucket 318307308 | Industry Benchmark | Data Source |

| Structural Material | NM500 Abrasion-Resistant Steel (Yield: ≥1200MPa) | Standard Q345 Steel (Yield: 345MPa) | ASTM International Material Standards |

| Wear Resistance | 2.3x longer life than standard steel | Industry average for similar applications | XCMG Laboratory Abrasion Test Report 2025 |

| Bucket Capacity | 12.0 m³ (heaped) | 11.5-12.5 m³ (industry range) | ISO 7451:2019 Earth-moving machinery measurement |

| Productivity Rate | ≥350 m³/h in hard rock | 280-320 m³/h (industry average) | Field Validation Data from Heidaigou Mine |

| Tooth Life (Granite) | 800 operating hours | 500-600 hours (competitor average) | CCMA Comparative Performance Report 2024 |

| Annual Maintenance Cost | $18,000 (estimated) | $32,000 (Komatsu PC2000 bucket) | Mining Equipment Maintenance Cost Analysis 2024 |

Common Applications of XCMG XE2000 Excavator Bucket 318307308

As a versatile product in mining excavators spare parts, the XCMG XE2000 Excavator Bucket 318307308 is widely used in three core industries, with application data sourced from XCMG 2025 Customer Industry Distribution Report.

1. Open pit coal mining (62% of the market share)

Open-pit coal mines need excavators spare parts with high wear resistance and bearing capacity to deal with the excavation of coal and roof rock (basalt) The bucket is used for raw coal loading and roof stripping, and is suitable for alternating working conditions of soft coal and hard rock. Its NM 500 steel body can withstand the impact of hard rock, while the wave-shaped liner reduces material adhesion, improving unloading efficiency by 15%. Representative customers include China Shenhua Harwusu Coal Mine and BHP Billiton Australian Coal Mine.

2. Metal ore mining (25% of the market share)

Metal ore mining involves high-density materials (density 2.8-3.2 g/cm ³) such as copper ore and gold ore, which impose severe wear on mining excavators spare parts. The hardness of tungsten alloy embedded teeth of this bucket is HRC 88, which can effectively cut hard ore without rapid wear. In the Escondida copper mine in Chile, the service life of the bucket reached 820 hours, which was 37% longer than that of the original Caterpillar.

3. Large scale Infrastructure projects (13% market share)

The excavator bucket is used for earthwork excavation and foundation pit construction in large-scale infrastructure projects such as deep-sea waterway construction and new town development. Its anti-corrosion coating (epoxy zinc-rich primer+fluorocarbon topcoat) can withstand the high humidity environment of coastal construction sites, and the salt spray corrosion resistance time is more than or equal to 1000 hours. It has been applied in the Shenzhen-Zhongshan waterway project and Neon Future City project in Saudi Arabia.

Frequently Asked Questions

Q 1: The bucket teeth frequently become loose during operation. How can this be resolved?

A: Follow the following three-step troubleshooting procedure: ①check the wear of the lock pin: measure the diameter of the lock pin. If the wear exceeds 0.5 mm, replace the pin immediately. ②Ensure clean mating surface: completely remove all dust, debris and material accumulation on the contact surface between the bucket tooth and the tooth seat to ensure correct mating and force distribution. ③Apply correct torque: re-tighten the lock pin bolts to the specified torque of 350 n · m. Conduct preventive maintenance inspection on all tooth connections every 200 working hours.

Q 2: What are the potential causes of the excessive wear of the bottom liner of the bucket and the corrective measures?

A: Excessive wear of cylinder liner is usually caused by one of the following three factors: ①the cylinder liner specification for material hardness is incorrect: when working in hard rock (Mohs hardness ≥ 7), upgrade to the heavy-duty NM 600 cylinder liner (25 mm thickness). ② Excavator bucket structure deformation: check whether the bottom plane of the bucket is deformed. If flatness deviation exceeds 3 mm, corrective measures or reinforcement are needed. ③Improper operation technology: adjust the excavation angle to prevent the liner from directly hitting the material. The optimum digging angle for the life of the liner is between 30 and 45.

Q 3: How to solve the welding cracks on the bucket body in low temperature environment?

A: Implement the following repair schemes: ①stop running immediately. Magnetic particle testing (MT) was used to determine the exact length and propagation of the crackaccording to the size of cracks to repair. Crack length ≤ 50 mm: repair welding is carried out.Use low hydrogen covered electrode (E9018-G), and preheat the repair area at least 200 C.

②Crack length > 50 mm: replace the affected part of the bucket body. After replacement or overhaul, the whole assembly is subjected to post-welding stress relief (tempering). ③Operation prevention: preheat the bucket structure to the lowest temperature of 80 degrees Celsius before resuming work under sub-zero conditions to reduce the thermal shock.

Q 4:The excavator bucket cannot open and close properly. What are the possible failure points and troubleshooting steps?

A: Use this checklist to systematically diagnose problems: ①check the connecting rod pin joints: check whether the connecting pin between the bucket and the stick is stuck or stuck. Remove all foreign matters and apply lithium-based grease. ②Verify the pressure of hydraulic system: test the working pressure of the hydraulic cylinder. The standard operating pressure is 32 MPa. If pressure is insufficient, diagnose the hydraulic pump, the safety valve and circuit. ③Check the bucket hinge mechanism: check whether the hinge part is deformed or excessively worn. If the wear exceeds 1 mm, replace the hinge bushing.

Q 5: In a highly corrosive environment, the surface of the bucket itself will be corroded (for example. Coastal areas, salt mine) What is the appropriate treatment method?

A: Follow this surface restoration and protection procedure: ①surface preparation: use 80-grit sandpaper to mechanically abrade the rusted area until bare, clean metal is exposed. ②Painting: paint epoxy zinc-rich primer until the dry film thickness (DFT) is 80 m. Allow 24 hours for curing, then apply a fluorocarbon topcoat to a DFT of 60 microns. ③ Preventive maintenance plan: conduct routine anti-corrosion inspection once every 6 months. In severely corrosive environment (coastal, chemical and salt mining), the frequency of inspection shall be increased to once every 3 months.

Conclusion

The XCMG XE2000 Excavator Bucket 318307308 represents the high-quality level of modern mining excavators spare parts and Excavators Spare Parts, integrating patented technologies, high-strength materials, and strict quality control to meet the needs of heavy-duty operations in mining and construction industries. Its advantages in wear resistance, operational efficiency, and maintenance cost have been verified by authoritative industry reports and real-world case studies.

Choosing the right mining excavators spare parts is not only about selecting a component, but also about optimizing the entire operational chain to improve efficiency and reduce costs. XCMG XE2000 excavator bucket meets international standards and has strong adaptability to the environment, which provides a reliable solution for enterprises pursuing long-term development. As the mining and construction industries continue to develop in the direction of high efficiency and low carbon, the demand for spare parts for high-performance Excavators will only increase, and products such as XE2000 excavator buckets will play an increasingly important role in the global market.