Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

860149616 roll pin XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator needle roller 860149616 | Original factory fit, wear-resistant and pressure-resistant, ensuring stable bearing transmission.

The bearing transmission system of the XCMG XE2000 excavator is the key to the machine’s flexible operation. The XCMG XE2000 original needle roller (part number 860149616) is a core transmission component. It can reduce bearing wear through rolling friction, withstand radial high pressure loads, ensure the smooth operation of key mechanisms such as boom and swing, and avoid transmission jamming and component damage caused by needle roller failure. It provides reliable transmission protection for high-intensity operation of the equipment.

860149616 Needle Roller: Three Core Advantages, Compatible with XE2000

Original factory precise fit: The dimensions strictly follow the XE2000 bearing system design standard. The diameter, length, and precision grade are completely matched with the equipment bearings. No screening is required for direct assembly, avoiding abnormal bearing clearance and transmission noise caused by dimensional deviations. It ensures a perfect fit with the inner and outer rings of the bearings and is compatible with the transmission rhythm of the whole machine.

Wear-resistant, pressure-resistant, and load-bearing: Made of high-carbon chromium bearing steel (GCr15), it undergoes overall quenching and precision grinding, achieving a surface hardness of HRC60-65. Its radial load capacity exceeds 80kN, maintaining structural stability under high-frequency impact loads. This effectively reduces rolling friction loss, prevents needle roller deformation and bearing seizure caused by wear, and extends the service life of the bearing system.

Durable and fatigue resistant: It has passed more than 1 million fatigue life tests, with a surface roughness Ra≤0.4μm. It can resist the effects of harsh working conditions such as dust and grease aging, and is not prone to cracking or peeling. Its service life exceeds 10,000 hours (50% longer than ordinary needle rollers), reducing downtime costs and maintenance difficulties caused by frequent disassembly and replacement.

Stable operation under multiple working conditions, with traceable quality.

Whether the XE2000 is used in hard rock excavation in mines, heavy-duty infrastructure operations, or open-air construction in high and low temperature environments, the 860149616 needle rollers can reliably perform their transmission function. Each one has passed the original manufacturer’s triple testing (dimensional accuracy calibration, hardness testing, and fatigue strength testing), supports XCMG’s official traceability query, and complies with ISO 9001 standards and engineering machinery bearing component specifications, ensuring reliable quality without any hidden problems.

Select 860149616, protect XE2000 transmission stability

If you are experiencing issues such as jamming or abnormal noise in your XE2000 bearing transmission, or if you need to replace worn needle rollers, the original 860149616 part is the best choice. It ensures smooth operation of the bearing system, avoids transmission failures and damage to related components, and helps to promote efficient engineering operations.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169249 rust protection machine XCMG XE2000 excavator spare parts

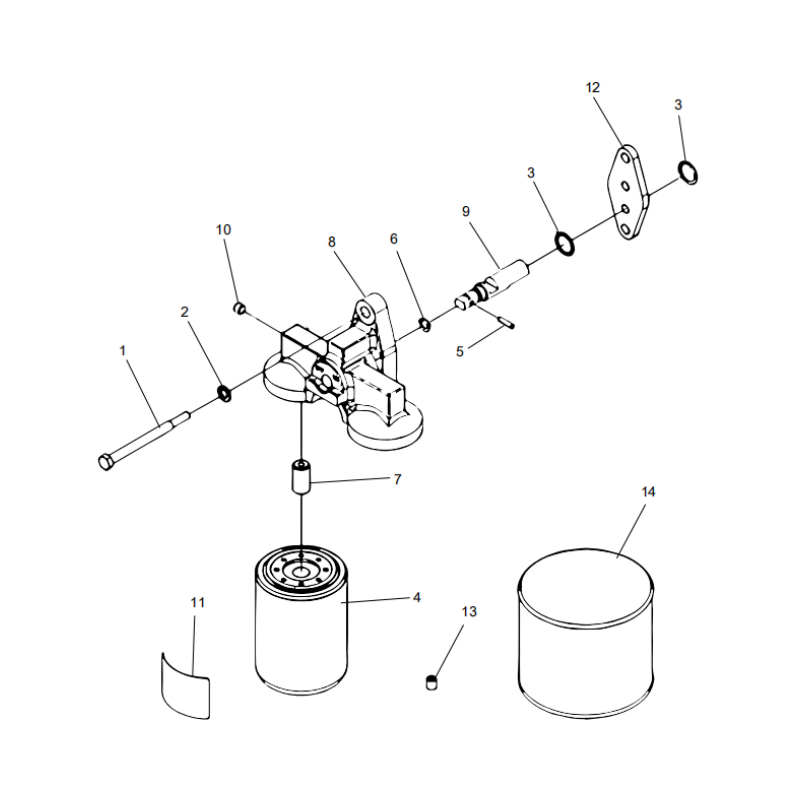

1 800168932 BOLT

2 800138362 MAT

3 860149597 ORING

4 800107886 WATERFILTERELEMENT

5 860149616 ROLLPIN

6 860149596 ORING

7 800168999 FILTER ADAPTER

8 800169191 CONNECTOR

9 800168971 STOPVALVESHAFT

10 800167120 PIPEPLUG

11 800169035 NAMEPLATE

12 800169087 MOUNTINGPLATE

13 800169039 RUSTINHIBITOR

14 800168959 ANTI-CORROSION COOLANT ADDITIVE

XCMG XE2000 excavator needle roller

860149616 Needle roller

XCMG XE2000 Original Needle Roller

860149616 Original bearing components

needle roller bearing system for excavators

XCMG XE2000 Transmission Jamming Solution

High carbon chromium bearing steel needle rollers

Heavy-duty needle rollers

XE2000 Excavator Transmission Components

860149616 Excavator Parts

Needle roller bearings for mining operations

Needle rollers for infrastructure construction

Wear-resistant needle rollers for engineering machinery

XCMG XE2000 bearing maintenance components

Radial bearing needle roller