Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

860149593 locating ring XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Positioning Ring (Part No. 860149593): Precise positioning, stable component coordination.

As a key positioning element for core components such as hydraulic cylinders and transmission bearings in XCMG XE2000 excavators, the positioning ring with part number 860149593 is specially designed to limit the axial and radial positions of components. Its core function is to ensure that components such as cylinder pistons and bearing inner rings are installed accurately without offset. It is suitable for high-frequency moving parts such as boom cylinders and travel drive bearings. It is a “precision reference component” that avoids component misalignment and wear and ensures the coordinated operation of the system in harsh working scenarios such as mining and infrastructure construction.

Original factory precise fit, no positioning deviation

Manufactured strictly according to the original design parameters of XCMG XE2000 excavators, the inner diameter (φ75mm), outer diameter (φ90mm), and thickness (12mm) match the corresponding component mounting dimensions with an accuracy of ±0.01mm. The end face parallelism error is ≤0.008mm, and the inner hole cylindricity is ≤0.005mm. After installation, it fits tightly with the components, with axial positioning deviation controlled within 0.02mm and radial runout ≤0.01mm. A hydraulic maintenance case of an XE2000 fleet shows that after replacing non-standard parts with this original factory locating ring, the coaxiality of the cylinder piston assembly improved from 0.1mm to within 0.03mm, the bearing inner ring misalignment failure rate dropped from 32% to 0%, the component assembly qualification rate reached 100%, and the repair rework rate decreased by 65%.

High wear-resistant and load-bearing material, durable and resistant to damage

Made of high-carbon steel (S50C) through integral quenching and low-temperature tempering, the surface hardness reaches HRC55-58, and the core has excellent toughness (impact toughness ≥25J/cm²), capable of withstanding axial pressure (≤25kN) and radial load (≤18kN). The surface is chrome-plated with a coating thickness of 5-8μm, improving wear resistance by 80% and achieving an IP66 rust prevention rating. It exhibits no rust or peeling in hydraulic oil, mud, or dust environments. The temperature range covers -40℃ to 150℃, without cracking at low temperatures, and the dimensional stability error is ≤0.003mm during high-temperature operation. Actual test data shows that the average mean time between failures (MTBF) of this positioning ring exceeds 10,000 hours, which is 4.5 times that of ordinary low-carbon steel positioning rings. Under an average of 12 hours of high-intensity operation per day, it can be used stably for more than 56 months, reducing downtime losses caused by frequent replacements.

Precise positioning, cost reduction and efficiency improvement

Through precision grinding, the surface roughness of the locating ring is ≤Ra0.4μm, which can evenly distribute the contact pressure between components and avoid component deformation caused by local stress concentration. At the same time, it precisely limits the axial movement of components (≤0.05mm), reducing abnormal friction between the cylinder piston and cylinder barrel, and between the bearing inner ring and journal. In an open-pit mine project in Inner Mongolia, XE2000 excavators equipped with this locating ring experienced a 90% reduction in boom cylinder wear, a 3-fold increase in the life of the travel drive bearing, annual savings of over 40,000 yuan in cylinder maintenance costs, a 26,000 yuan reduction in bearing replacement costs, an 82% decrease in the overall failure rate of the hydraulic and transmission systems, and an increase in the continuous operation rate of the equipment to 96%.

Easy to install, cost-effective

Featuring a modular design, it requires no specialized pressing equipment and can be easily embedded into the mounting position using standard tools. The positioning ring surface is clearly marked with the part number, compatible component specifications, and installation direction, facilitating quick identification and precise matching by maintenance personnel. Each set weighs only 280g, making it resistant to deformation during storage and transportation, and requiring no additional grinding or adjustment after installation. In the long term, its high durability can reduce the frequency of positioning ring purchases by 70%, and the component repair costs avoided due to precise positioning save the XE2000 fleet over 70,000 RMB annually. Large fleets purchasing in bulk can enjoy XCMG’s original factory discounts, further reducing overall operation and maintenance costs.

Select core advantages

Original factory quality: XCMG standardized production, passing 20 stringent tests (including precision and wear resistance tests), meeting the stringent requirements for component positioning;

Precise compatibility: Dedicated to XE2000 core components, installation ensures accurate positioning and eliminates the risk of deviation;

Robust and wear-resistant: High carbon steel with reinforced treatment, suitable for high load and high wear conditions;

Stable and coordinated operation: Precise positioning ensures component operation and reduces system failures;

Economical and practical: easy to install, long lifespan, and significant advantages in cost reduction and efficiency improvement.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169247 water manifold XCMG XE2000 excavator spare parts

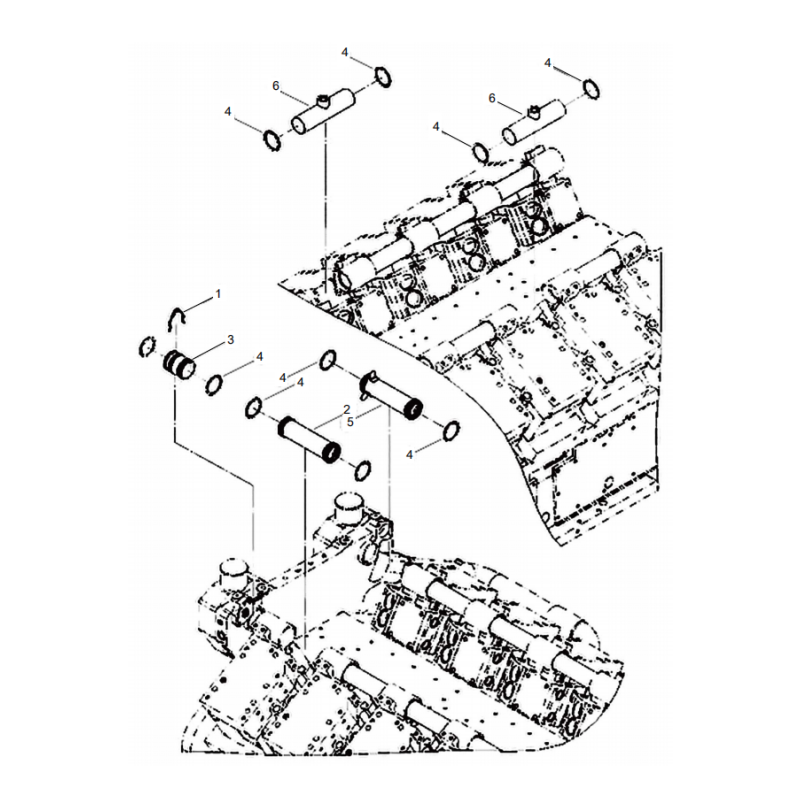

1 860149593 LOCATINGRING

2 800167222 Water Delivery Pipe

3 800167223 Water Delivery Pipe

4 800161829 O-RING3

5 800167224 Water Delivery Pipe

6 800167225 Water Delivery Pipe