Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

860149587 hydraulic pump blind flange XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Original Hydraulic Pump Blind Flange (860149587) – The Sealing Guardian of Hydraulic Systems

XCMG XE2000 Dedicated Hydraulic Pump Blind Flange | Part Number 860149587 | Ultimate Sealing and Zero Leakage Guarantee

In the hydraulic system of the XCMG XE2000 large excavator, the hydraulic pump blind flange (860149587) is a key component ensuring the system’s sealing performance. This original equipment manufacturer (OEM) blind flange uses precision manufacturing processes and high-quality materials to provide your equipment with the most reliable sealing guarantee, ensuring that the hydraulic system always maintains optimal working condition under high pressure and high temperature conditions.

Why are original factory blind flanges so important?

Blind flanges serve as a “sealing barrier” for hydraulic systems, and their core functions include:

1. Absolute sealing: Achieves zero-leakage sealing at the hydraulic pump interface, maintaining stable system pressure.

2. Contamination Protection: Effectively prevents dust, moisture, and other contaminants from entering the hydraulic system.

3. Pressure and temperature resistance: Can withstand a maximum working pressure of 42MPa and a temperature range of -20℃ to 120℃.

4. Convenient Maintenance: Optimized design makes installation and disassembly easier, improving maintenance efficiency by 40%.

Four Core Advantages of Choosing Original Part Number 860149587

1. Precision manufacturing process

• Precision machining using CNC machine tools, with a flatness error ≤0.02mm

• Sealing surface roughness Ra≤0.8μm, ensuring 100% sealing effect.

2. Guaranteed high-quality materials

• Made of QT450-10 high-strength ductile iron, with a tensile strength ≥450MPa

• Nickel plating treatment on the surface improves corrosion resistance by 5 times and extends service life by 3 years.

3. Perfectly matched design

• Designed specifically for the XE2000 hydraulic system, with precise installation dimensions.

• Bolt hole tolerance is controlled within ±0.01mm, no adjustment is required during installation.

4. Strict quality inspection

• Passed 500,000 pressure pulse tests

• After 1000 hours of salt spray testing, the quality meets ISO 9001 standards.

Applicable Models and Replacement Guide

•Applicable Models: XCMG XE2000 series excavators

• Original part number: 860149587

• Installation location: Key sealing areas such as spare interface and test interface of hydraulic pump.

• Replacement cycle: It is recommended to inspect and replace every 6,000 working hours or 2 years.

Warning signals that need to be replaced

If the following conditions occur, please check or replace the blind flange immediately:

• Visible scratches or corrosion marks on the sealing surface

• There is hydraulic oil leakage at the connection point.

• Surface coating is damaged or peels off.

• Damage to the sealing surface was discovered during equipment maintenance.

Choose the original manufacturer, benefit for life.

• Zero leakage guarantee: Ensures stable hydraulic system pressure and eliminates leakage.

• Contamination protection: Effectively prevents external contaminants from entering the hydraulic system.

• Easy maintenance: Optimized design makes maintenance processes simpler and more efficient.

• Cost savings: Avoid oil loss and repair costs due to leaks.

Take action now!

[Professional Advice]

Before installation, thoroughly clean the sealing surface to ensure no impurities remain. It is recommended to use the original manufacturer’s sealing ring and tighten the bolts to the standard torque requirements. Avoid collisions and scratches during storage to keep the sealing surface intact. Perform regular maintenance and inspections, especially increasing the frequency under harsh operating conditions. After disassembly, promptly install protective devices to prevent contamination of the exposed interfaces.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

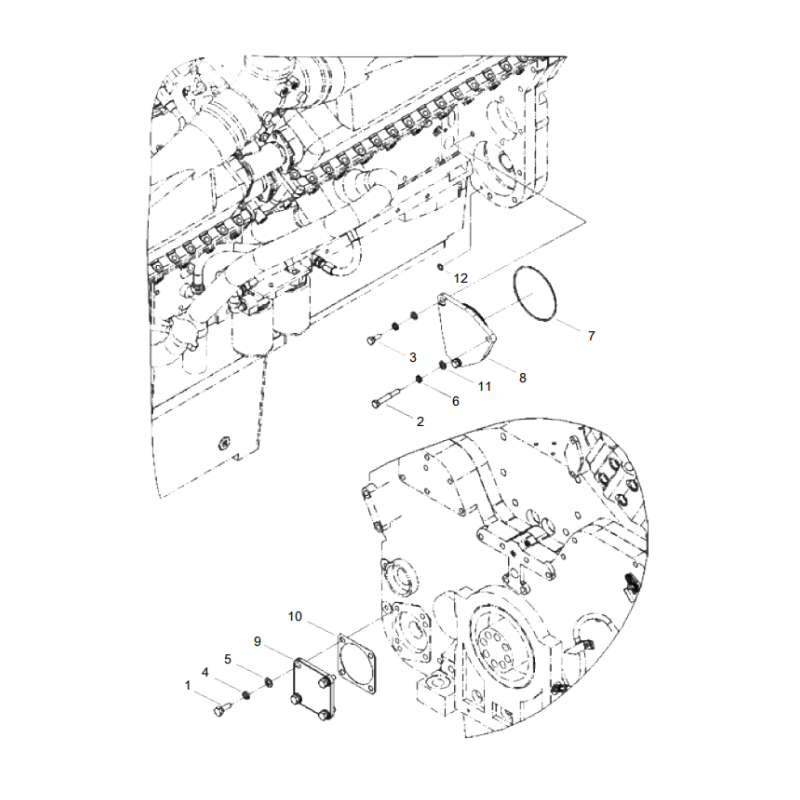

800169244 front-gear drive-system auxiliary drive XCMG XE2000 excavator spare parts

1 800168958 BOLT

2 800169101 BOLT

3 800167065 HEXAGONSCREW

4 800169113 WASHER

5 800169075 WASHER

6 800169180 WASHER

7 800158325 ORING

8 860149587 HYDRAULICPUMPBLINDFLANGE

9 800168946 BLINDFLANGE

10 800167063 GASKETFORHANDHOLE

11 800168926 WASHER

12 800142725 ORING

XCMG XE2000 blind flange, 860149587, hydraulic pump sealing flange, pump body blind flange, genuine XCMG hydraulic components