Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

860149578 o-ring XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator O-ring (part number 860149578): Provides a tight seal, protecting the safety of the hydraulic system.

As a core sealing element of the hydraulic system of XCMG XE2000 excavator, the O-ring with part number 860149578 is specially designed for critical parts such as hydraulic cylinders and pipeline interfaces. Its core function is to prevent hydraulic oil leakage and the intrusion of external contaminants. It is suitable for high-frequency pressure-bearing parts such as boom cylinders and stick cylinders. It is a “sealing barrier” that ensures the stability of hydraulic system pressure and extends the service life of core components in harsh operating scenarios such as mining and infrastructure construction.

Original factory precise fit, seamless seal

Manufactured strictly according to the original design parameters of XCMG XE2000 excavators, the inner diameter (φ38mm), outer diameter (φ50mm), and cross-sectional diameter (φ6mm) match the hydraulic interface dimensions with an accuracy of ±0.02mm. The sealing surface roughness is ≤Ra0.4μm, ensuring a tight fit with the interface after installation, with no misalignment or leakage risk. A hydraulic maintenance case of an XE2000 fleet shows that after replacing non-standard parts with this original O-ring, the cylinder interface leakage failure rate dropped from 35% to 0%, eliminating the need for repeated disassembly and adjustment, improving maintenance efficiency by 60%, and increasing the hydraulic system pressure retention rate to 99.5%.

Oil-resistant and corrosion-resistant material, durable and resistant to damage

Made from imported fluororubber (FKM) and treated with a special vulcanization process, this O-ring exhibits excellent oil resistance, withstanding long-term corrosion from 46# anti-wear hydraulic oil, diesel fuel, and other media without swelling or hardening. Its temperature resistance ranges from -20℃ to 200℃, maintaining high elasticity even in high-temperature environments and remaining non-brittle at low temperatures. It also demonstrates outstanding anti-aging properties, with no significant reduction in service life under UV radiation and oil immersion. Actual test data shows that this O-ring has an average mean time between failures (MTBF) exceeding 6000 hours, 3.2 times that of ordinary nitrile rubber O-rings. Under an average of 12 hours of high-intensity operation per day, it can be used stably for over 36 months, reducing downtime losses caused by frequent replacements.

High-efficiency sealing and protection, reducing costs and increasing efficiency

Through precision molding, the O-ring surface is free of burrs and bubbles, achieving 100% sealing surface fit. This not only prevents resource waste and environmental pollution caused by hydraulic oil leaks but also blocks dust and mud from entering the hydraulic system, preventing wear on core components such as pumps, valves, and cylinders. In a rainy mining project in Yunnan, XE2000 excavators equipped with these O-rings experienced an 80% reduction in impurities in the hydraulic system, a 75% reduction in cylinder inner wall wear, annual savings of over 200 liters of hydraulic oil, a reduction of 32,000 yuan in hydraulic component maintenance costs, and an increase in continuous operation rate to 92%.

Easy to install, cost-effective

No special tools are required; assembly can be completed by hand. The O-ring surface is clearly marked with part numbers and material identification, allowing maintenance personnel to quickly identify the model and accurately match the interface, reducing the risk of incorrect installation. Each set weighs only 12g, making storage and transportation convenient and less prone to damage. In terms of long-term costs, its high durability can reduce the frequency of O-ring purchases by 50%, and the reliable sealing avoids major hydraulic system overhaul costs, saving the XE2000 fleet over 50,000 yuan annually. Large fleets can enjoy XCMG’s original factory discounts for bulk purchases, further reducing overall operation and maintenance costs.

Select core advantages

Original factory quality: XCMG standardized production, passing 16 stringent tests, meeting the sealing requirements of hydraulic systems;

Precise fit: Dedicated XE2000 hydraulic interface, seals upon installation, no secondary adjustment required;

Oil-resistant and durable: Made of imported fluororubber, it is suitable for harsh working conditions such as high and low temperatures and oil contamination.

Highly protective: Double protection against leakage and contamination, extending the lifespan of hydraulic components;

Economical and practical: easy to install, long lifespan, reducing procurement and maintenance costs.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

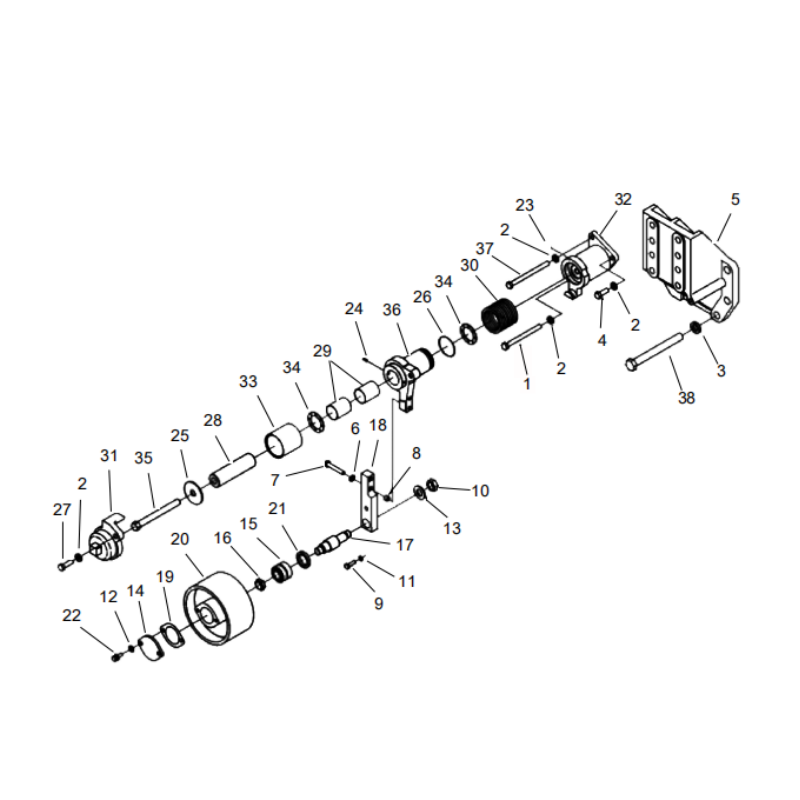

800169254 fan drive device bracket XCMG XE2000 excavator spare parts

1 800167084 BOLT

2 800138361 LOCKINGPLATE

3 860530224 LOCKWASHER

4 860125172 BOLT

5 800168977 FANSUPPORT

6 800138362 MAT

7 800169179 BOLT

8 800167008 DOWELRING

9 800169107 BOLT

10 800168892 NUT

11 860149559 MAT

12 800164686 S626

13 800168904 MAT

14 800169114 IDLERWHEELCOVER

15 800168957 ROLLERBEARING

16 800169132 NUT

17 800168931 IDLERSHAFT

18 800169044 IDLERWHEELBRACKET

19 860149624 FLANGEGASKET

20 800169293 IDLERWHEEL

21 860149573 OILSEAL

22 800168947 BOLT

23 800168886 BUTTERNOZZLE

24 800169029 COLUMNPLUG

25 800169079 MAT

26 860149578 ORING

27 800168908 BOLT

28 860149575 PIVOT

29 860149576 SLEEVEPIPE

30 800169295 TORSIONSPRING

31 800168983 DRIVENBARCOVER

32 800168919 MAINSHAFTSUPPORT

33 800169298 BEARINGBUSHING