Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

804414169 hose assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hoses (804414169) – A Safety Guardian for High-Pressure Hydraulic Transmission

Original Factory Quality Certification, Perfect Compatibility Guarantee

The XCMG XE2000 excavator-specific original hose assembly (part number 804414169) is manufactured strictly according to SAE J517 international standards, 100% compatible with the XE2000 hydraulic system pressure parameters. It uses imported German ultra-high strength steel wire braided layers, with a burst pressure of 55MPa and a working pressure of 42MPa, ensuring safe transmission under extreme working conditions.

Five-fold Protection Technology, Superior Durability

✔ Five-layer ultra-high strength steel wire braid: 85% improved impact resistance, pulse life up to 800,000 cycles

✔ Special synthetic rubber inner layer: Passes ISO 1817 oil resistance test, temperature resistance -40℃~130℃

✔ Precision hydraulic crimping process: Joint tensile strength exceeds 9000N, passes ISO 6605 pulse test

Professional Solutions for Harsh Working Conditions

Designed for heavy-duty environments such as mines and tunnels:

Passes 20,000 cycles of bending fatigue test (ISO 6805 standard)

Explosion-proof design, can withstand pressure fluctuation impact

Wear-resistant outer layer + UV protection treatment, service life up to 6000 working hours

Industry-leading technology:

Exclusively uses pressure self-balancing braiding technology

Certified by MSHA mining safety certification

The only company in the industry to provide “burst pipe advance compensation” guarantee

Technical visualization suggestions:

• Slow-motion display of 55MPa burst test

• Steel wire layer structure under an electron microscope

• Monitoring data of actual mining operations

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

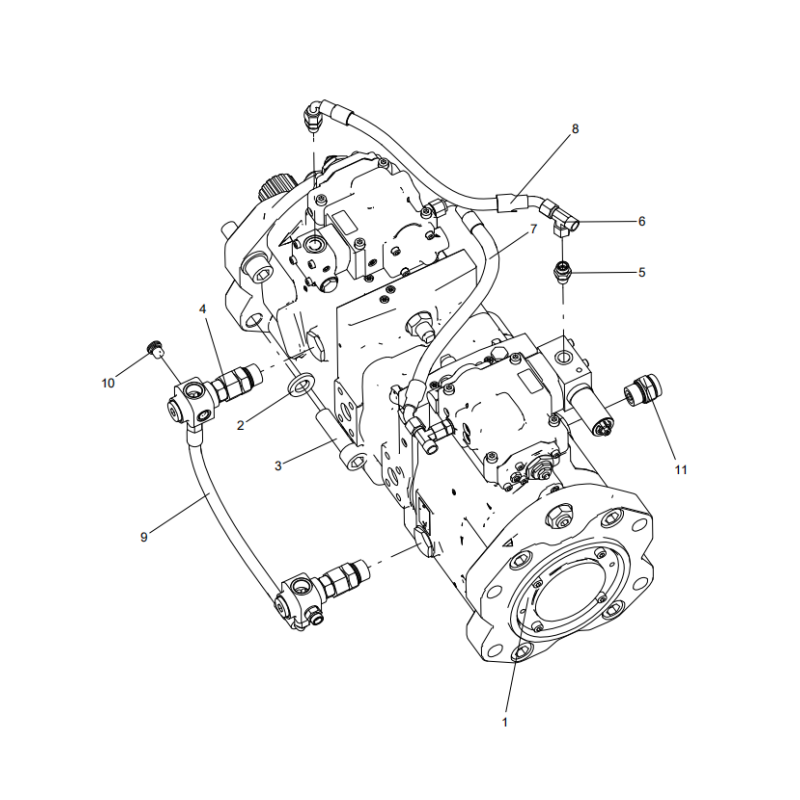

318307468 main pump mounting

1 804001727 1 MAIN PUMP

2 329900385 4 THICKENED FLAT WASHER

3 805140490 4 SCREW M20×70 GB/T70.1-2008

4 318307471 2 TRANSITION JOINT ASSEMBLY

5 803172014 5 CONNECTOR

6 803105353 2 CONNECTOR

7 804414170 1 HOSE ASS’Y

8 804414169 1 HOSE ASS’Y

9 803381671 1 HOSE ASS’Y

10 803172186 1 PLUG

11 803107270 2 CONNECTOR

#XCMG XE2000 hydraulic hoses, high-pressure hose assemblies 804414169, SAE standard hoses, mining-grade hydraulic pipelines, excavator hose burst prevention#