Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

804414143 hose assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hose Assembly (804414143): The Flexible Core Hub of Power Transmission in Mining

In core mining regions worldwide, such as Indonesia, the Democratic Republic of Congo, and Brazil, the XCMG XE2000 mining excavator, with its 12-cubic-meter super-large bucket capacity and over 93% mobility, has become a core piece of equipment for efficient mining operations. In the power transmission system of this “mining giant,” the hose assembly with part number 804414143 acts as a “flexible power artery,” undertaking the precise delivery of critical media such as hydraulic oil and coolant, and is a crucial core spare part ensuring the continuous and stable operation of the entire machine.

Original Factory Direct Adaptation, Precisely Connecting to the Machine’s Piping System

The XCMG XE2000 hose assembly (804414143) was specifically developed by the XCMG R&D team for the overall piping layout of the XE2000 machine, and optimized through 3D modeling simulation and extensive real-machine testing. Its length error is strictly controlled within ±1mm, and the connector specifications and angles are perfectly matched with the interface parameters of core components such as the hydraulic pump, main valve, and bucket cylinder. Whether in the dynamic scenario of high-frequency bucket operation or the static installation environment of complex internal piping, it can achieve seamless, zero-gap installation, effectively avoiding problems such as pipe twisting, friction, and stress concentration, creating a highly efficient “seamless” power transmission channel for the entire machine.

Multi-layer reinforced materials, a durable choice for extreme working conditions

Crafted with five layers of composite reinforced materials: the inner layer is imported high-pressure resistant hydrogenated nitrile rubber, capable of withstanding instantaneous pressure impacts of 340MPa, with excellent resistance to hydraulic oil corrosion; the middle layer is embedded with 6 layers of high-tensile steel wire braided mesh, with a tensile strength of up to 1700N/mm², ensuring that the hose does not expand or deform under high pressure; the outer layer is covered with wear-resistant EPDM rubber, possessing excellent ozone resistance, UV resistance, and high and low temperature resistance. After rigorous testing, this hose assembly maintains stable performance in extreme temperature ranges from -40℃ to 120℃ and in high-dust mining environments, extending its service life by more than three times compared to ordinary hoses. This significantly reduces downtime and maintenance costs caused by hose failures.

Low-resistance, high-efficiency transmission enhances overall machine performance

The hose’s inner wall undergoes precision honing, achieving a surface roughness Ra≤0.5μm, reducing media flow resistance by more than 15% compared to traditional hoses. When the XE2000 excavator is operating at full load, it ensures hydraulic oil reaches all actuators with a transmission efficiency of over 98%, providing continuous power support for the powerful digging action of the 12 cubic meter bucket. Simultaneously, its excellent flow stability reduces action delays caused by media transmission lag, shortening the overall machine cycle time by 7%, significantly improving operational efficiency and productivity in mining projects. For mining companies committed to efficient operations, the XCMG XE2000 hose assembly (804414143) is not only a high-quality spare part, but also a fundamental guarantee for continuous equipment output. Choosing original equipment manufacturer (OEM) spare parts means choosing reliability that perfectly matches the performance of the XE2000 excavator, providing a solid guarantee for the efficient advancement of mining operations.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

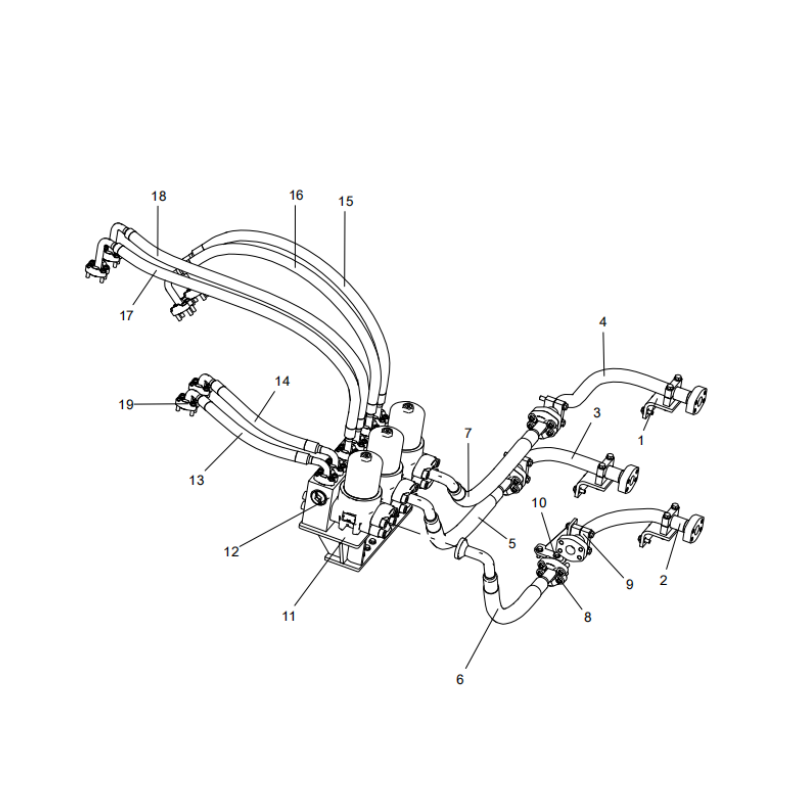

318307797 main pump system pipe

1 318307828 3 PIPE CLAMP ASSEMBLY

2 318307829 1 STEEL PIPE ASSEMBLY

3 318307826 1 STEEL PIPE ASSEMBLY

4 318307827 1 STEEL PIPE ASSEMBLY

5 804414162 1 HOSE ASS’Y

6 804414142 1 HOSE ASS’Y

7 804414414 1 HOSE ASS’Y

8 803164322 3 FLANGE ASSEMBLY

9 318006991 3 PIPE CLAMP ASSEMBLY

10 318307824 1 PIPE CLAMP ASSEMBLY

11 318307835 1 FILTER SUPPORT ASSEMBLY

12 318307832 3 HIGH-PRESSURE FILTER ASSEMBLY

13 804414135 1 HOSE ASS’Y

14 804414163 1 HOSE ASS’Y

15 804414164 1 HOSE ASS’Y

16 804414166 1 HOSE ASS’Y

17 804414143 1 HOSE ASS’Y

18 804414144 1 HOSE ASS’Y

19 803201542 6 FLANGE ASSEMBLY