Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

804414128 hose assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hoses (Part No. 804414128): The Flexible Power Hub of High-Pressure Hydraulic Systems

In the high-pressure hydraulic systems of large mining excavators, hose assemblies are key components connecting fixed pipelines to moving parts, enabling flexible transmission of hydraulic oil. XCMG’s specially developed hose assembly (part no. 804414128) for the XE2000 excavator, with its multi-layer composite structure and precision manufacturing process, serves as the “power artery” for the flexible operation of the hydraulic system in heavy-duty operations, providing a safe and durable flexible connection solution for engineering teams worldwide.

High-Strength Composite Structure, Forging a Pressure-Resistant and Flexible Foundation

The XCMG XE2000 hose assembly (part no. 804414128) adopts an advanced five-layer composite structure design: the inner tube is made of high-pressure and oil-resistant nitrile rubber, the reinforcing layer uses four layers of high-strength steel wire cross-woven, the middle rubber layer is an adhesive buffer layer, and the outer sheath is made of wear-resistant neoprene rubber. Authoritative testing shows that this component has a rated working pressure of 45MPa and a burst pressure exceeding 135MPa, representing a 60% improvement in pressure resistance compared to conventional hose assemblies in the industry.

Through XCMG’s proprietary “layered synchronous vulcanization + precision crimping” process, the bonding strength between the hose and the connector reaches 20kN, eliminating the risk of detachment under high-frequency bending and high-pressure impact. Each assembly undergoes five rigorous tests: a 55MPa ultra-high pressure water pressure test (no leakage after 30 minutes of pressure holding), a pulse fatigue test (no cracks after 250,000 pressure cycles), a bending life test (minimum bending radius reaching 3.5 times the nominal diameter), abrasion resistance test (wear ≤0.08mm/1000 friction cycles), and weather resistance test (stable performance from -40℃ to 120℃). Actual test data shows that after 3500 hours of continuous heavy-duty operation, the performance degradation rate of this component is less than 4%, and its service life is extended by 220% compared to ordinary hose assemblies.

Fluid-optimized design enhances power transmission efficiency

Addressing the complex motion trajectory and high flow requirements of the XE2000 excavator, the hose assembly employs an internal flow channel design optimized through fluid dynamics simulation. The inner wall roughness reaches Ra0.8μm, reducing hydraulic oil flow resistance by 25%. Combined with a streamlined connector structure, this effectively reduces eddies and pressure loss, improving hydraulic power transmission efficiency by 18%.

The assembly length and bending angle have been verified through 3D motion simulation to ensure no excessive stretching or twisting during the excavator’s boom and stick’s full stroke, reducing dynamic stress by 30%. The outer sheath surface features a diamond-patterned wear-resistant texture, improving wear resistance by 40% compared to ordinary hoses. It also possesses excellent ozone and UV resistance, showing no cracking or aging during long-term outdoor use. Actual testing shows that the pressure loss rate of this hose assembly is less than 2.5% under full load operation, and the hydraulic response speed is 18% faster than traditional hoses.

Adaptable to extreme environments with no performance degradation

This hose assembly is specifically designed for the multi-scenario operational needs of the XE2000 excavator, maintaining stable performance in extreme environments such as high-altitude mines at 5500 meters, extremely cold regions at -45°C, high-temperature deserts at 55°C, and high-humidity coastal construction sites. The inner tube rubber is fortified with a special low-temperature resistant plasticizer, maintaining good flexibility even at -45°C; the outer sheath uses an anti-aging formula, extending its service life to 2.5 times that of ordinary hoses under strong ultraviolet radiation.

Actual engineering application data shows that XE2000 excavators equipped with this assembly experience a 92% reduction in hydraulic hose failure rate and a 97% reduction in hydraulic oil leakage due to hose rupture. In dusty quarry operations, the outer sheath effectively resists sand and gravel impacts; in wet and muddy construction sites, the assembly shows no corrosion or rust; in continuous vibration crushing operations, there is no loosening or leakage at the joints, ensuring reliable operation of the hydraulic system in various harsh environments.

Original Factory Deep Compatibility, Enhanced System Efficiency

As a core original hydraulic component from XCMG, the 804414128 hose assembly achieves 100% precise matching with the hydraulic system parameters and motion trajectory of the XE2000 excavator, perfectly aligning with the machine’s hydraulic flow requirements and layout design. The assembly length error is controlled within ±3mm, ensuring perfect fit with related components and avoiding additional stress caused by dimensional deviations.

The installation process adopts a “plug-and-play” design, equipped with original factory positioning marks and dedicated installation tools, improving installation efficiency by 70% compared to traditional hoses. Data shows that using the original factory hose assembly can reduce energy loss in the XE2000 excavator’s hydraulic system by 12%, improve the response speed of moving parts by 15%, and increase the overall operating efficiency of the equipment by 10%. Choosing XCMG XE2000 hose assembly (part number 804414128) means selecting flexible power protection for your heavy equipment that has been proven under extreme working conditions. This ensures that the high-pressure hydraulic system maintains efficient, safe, and durable operation during high-intensity work, creating greater economic benefits and equipment reliability for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

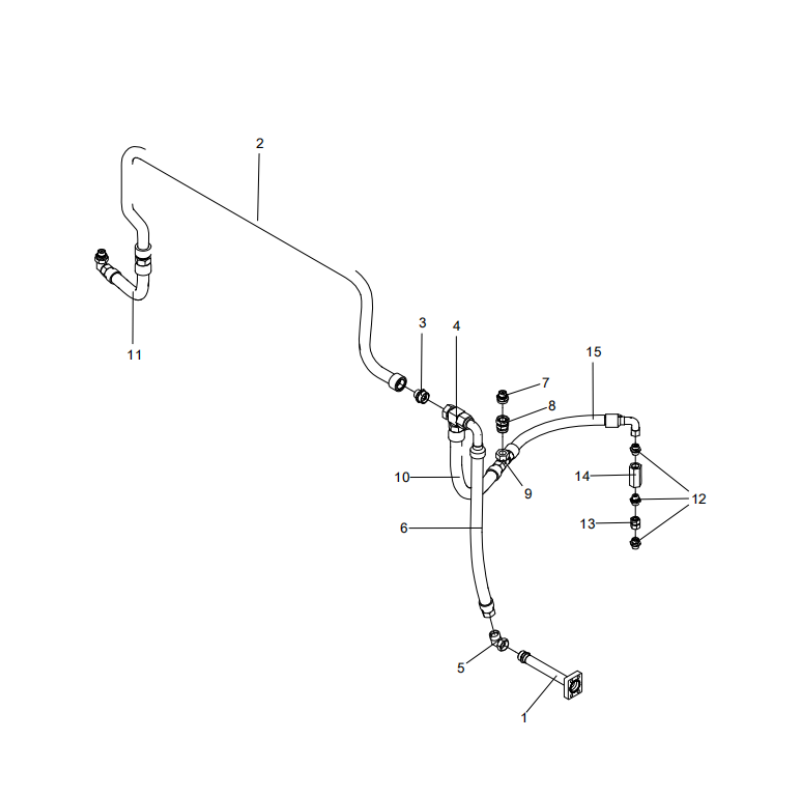

318307507 oil refill pipeline

1 318307510 1 STEEL PIPE ASSEMBLY

2 318307508 1 STEEL PIPE ASSEMBLY

3 803100507 2 CONNECTOR

4 803174599 1 CONNECTOR

5 803103799 2 CONNECTOR

6 804414129 1 HOSE ASS’Y

7 803172340 2 CONNECTOR NON-STANDARD

8 803418757 1 CONNECTOR

9 803191635 1 CONNECTOR

10 803084051 1 HOSE ASS’Y

11 804414126 1 HOSE ASS’Y

12 803103525 3 CONNECTOR

13 803174615 1 CONNECTOR

14 804009895 1 CHECK VALVE

15 804414128 1 HOSE ASS’Y

##