Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803499798 hose assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hose Assembly (Part No. 803499798): Reliable Transmission, Facilitating Efficient Construction

In high-intensity operations such as large-scale mining and heavy infrastructure projects, the XCMG XE2000 excavator has become a mainstay in construction due to its powerful operational capabilities. The hose assembly (part no. 803499798), as a key flexible connection component in the machine’s fluid transmission system, bears the heavy responsibility of safely and efficiently transmitting media such as hydraulic oil and lubricating oil, laying a solid foundation for the stable operation of the XE2000 under complex working conditions.

Dedicated Fit, Perfect for the Entire Machine System Requirements

The XCMG XE2000 excavator has a precise structure, and each system has extremely high standards for the pressure, flow rate, and sealing of fluid transmission. The hose assembly (part no. 803499798) is specifically tailored to the XE2000’s system parameters and installation layout, precisely matching the high-pressure working conditions of the hydraulic system (maximum working pressure up to 35MPa) and the media transmission requirements of lubrication, cooling, and other systems. Whether connecting hydraulic pumps and cylinders or delivering lubricating oil in lubrication lines, this hose assembly perfectly adapts to all components of the machine, ensuring unobstructed fluid flow in complex pipelines. It provides reliable flexible connection support for the XE2000’s powerful output and the flexible operation of its various mechanisms.

Reinforced Structure for Harsh Operating Environments

Mining environments are challenging; severe vibrations, extreme temperature variations, and dust corrosion can all affect the performance of hose assemblies. The XCMG XE2000 hose assembly (part number 803499798) adopts a multi-layer reinforced composite structure design. The inner layer uses high-pressure and oil-resistant high-quality rubber material, effectively resisting corrosion from hydraulic oil, lubricating oil, and other media, eliminating leakage problems during transmission. The middle reinforcing layer uses a high-strength steel wire braiding process, significantly improving the hose’s pressure resistance and burst resistance, maintaining structural stability even under high-frequency vibration environments. The outer layer uses wear-resistant and aging-resistant special rubber, effectively resisting external friction, ultraviolet radiation, and chemical damage. This reinforced structure allows the hose assembly to operate stably within a temperature range of -40℃ to 120℃, easily withstanding the challenges of various harsh operating environments.

Flexibility Enhances Equipment Stability

Compared to rigid piping, the hose assembly (part number 803499798) possesses excellent flexibility and vibration resistance. During operation of the XCMG XE2000 excavator, the boom, stick, bucket, and other working devices undergo frequent and significant movements, causing the connecting piping to experience substantial displacement and vibration. This hose assembly, with its excellent flexibility, can deform flexibly with the equipment’s movements, effectively absorbing vibration energy, reducing stress concentration caused by rigid connections, and lowering the probability of pipe joint loosening and breakage. Simultaneously, its precise length and bending radius design ensures that excessive stretching or twisting does not occur throughout the entire range of equipment movement, guaranteeing the continuity and stability of fluid transmission, thereby improving the overall reliability of the machine.

Strict Quality Control for Long-Term Durability

XCMG maintains strict quality control over its components. The hose assembly (part number 803499798) undergoes meticulous testing at every step, from raw material selection to production. Key indicators such as the oil resistance of the inner rubber layer, the strength of the reinforcing steel wire, and the wear resistance of the outer rubber layer are all verified through professional laboratory testing. Finished hose assemblies also undergo rigorous tests including pressure resistance, burst testing, and bending fatigue testing to ensure that every product meets XCMG’s high-quality standards. This stringent quality control process gives the hose assembly an exceptionally long service life, significantly reducing equipment maintenance and replacement frequency, minimizing downtime, and saving users overall operating costs.

Choosing the XCMG XE2000 excavator hose assembly (part number 803499798) means choosing safe and reliable fluid transmission and long-lasting stable operational support. As an important component of XCMG’s high-quality parts system, it will provide your XE2000 excavator with continuous flexible power transmission during high-intensity operations, facilitating efficient project execution. For more information on product specifications, sourcing channels, or technical support, please feel free to contact us. Let our professional accessories safeguard your equipment.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

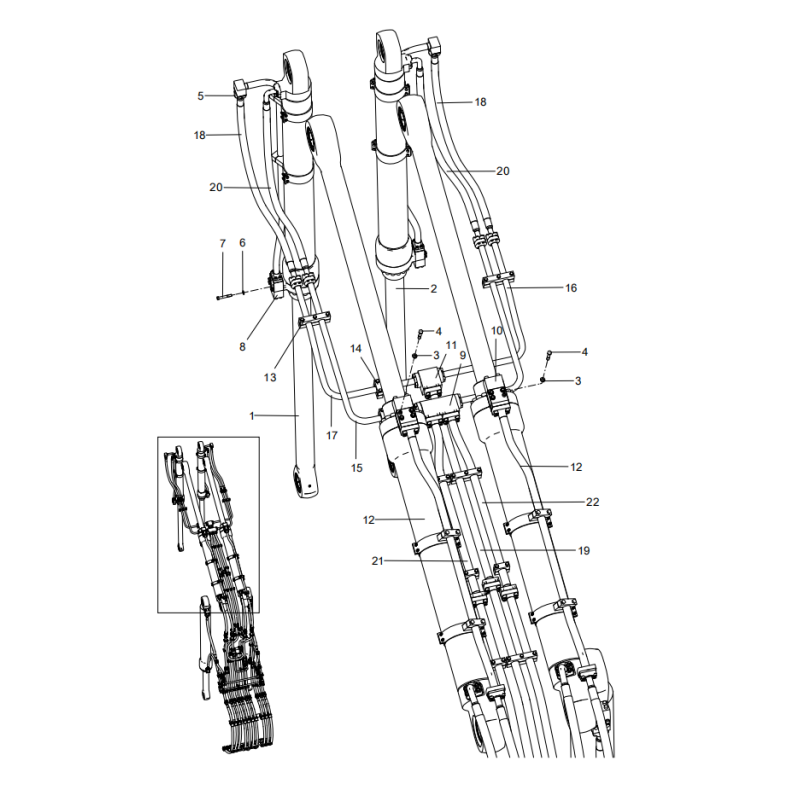

318307969 working device piping

1 804009182 1 LEFT BUCKET CYLINDER

2 804009180 1 RIGHT BUCKET CYLINDER

3 329900385 16 THICKENED FLAT WASHER

4 805046676 8 BOLT M20×140 GB/T5782-2000

5 803164322 12 FLANGE ASSEMBLY

6 329900304 12 THICKENED FLAT WASHER

7 805006392 8 BOLT M16×110 GB/T5782-2000

8 804009187 2 ONE-WAY THROTTLE VALVE

9 318301048 1 BLOCK

10 804023795 2 ONE-WAY THROTTLE VALVE

11 318301047 1 BLOCK

12 804009181 2 BUCKET ARM CYLINDER

13 318300984 2 PIPE CLAMP ASSEMBLY

14 318300988 7 PIPE CLAMP ASSEMBLY

15 318300987 2 STEEL PIPE ASSEMBLY

16 318300986 1 STEEL PIPE ASSEMBLY

17 318300990 1 STEEL PIPE ASSEMBLY

18 803432824 2 HOSE ASS’Y

19 318300999 1 STEEL PIPE ASSEMBLY

20 803499798 2 HOSE ASS’Y

21 318301024 1 STEEL PIPE ASSEMBLY

22 318301000 1 STEEL PIPE ASSEMBLY

##