Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803432820 hose assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hose Assembly (Part No. 803432820): Flexible Transmission Core, Safeguarding Efficient Operation

In high-intensity operation scenarios such as large-scale mining and heavy engineering construction, the XCMG XE2000 excavator, with its powerful performance, has become a core piece of construction equipment. The hose assembly (part no. 803432820), as the flexible connection core of the machine’s fluid transmission system, bears the heavy responsibility of safely and efficiently transmitting key media such as hydraulic oil and lubricating oil, providing indispensable flexible support for the stable operation of the XE2000 under complex working conditions.

Precise Adaptation, Meeting the Needs of the Entire Machine System

The XCMG XE2000 excavator has a precise and complex structure, and its various hydraulic and lubrication systems have stringent requirements for the pressure, flow rate, and sealing of the media transmitted. The hose assembly (part number 803432820) is custom-designed for the XE2000’s overall parameters and piping layout, precisely matching the high-pressure working environment of the hydraulic system (maximum working pressure up to 35MPa) and the media transmission standards of different systems. Whether connecting hydraulic actuators and control valves or creating flexible delivery channels in lubrication lines, this hose assembly perfectly adapts to all components of the machine. Its optimized length and bend design ensures unobstructed connections within the equipment’s compact structural space, providing reliable flexible transmission for the XE2000’s powerful output and flexible operation of its various mechanisms.

Multi-layer reinforced structure withstands extreme working conditions

The mining environment is challenging; high-frequency vibration, alternating high and low temperatures, and dust erosion can all affect the performance of the hose assembly. The XCMG XE2000 hose assembly (part number 803432820) features a multi-layer composite reinforced structure. The inner layer uses a special synthetic rubber that is resistant to high pressure and oil, effectively resisting long-term corrosion from media such as hydraulic oil and lubricating oil, ensuring no leakage during transmission. The middle reinforcing layer uses a high-strength steel wire braiding process with precise braiding density control, giving the hose excellent pressure resistance and burst resistance, maintaining structural stability even under high-frequency vibration. The outer layer uses wear-resistant and aging-resistant protective rubber, effectively resisting external friction, ultraviolet radiation, and chemical damage, extending the hose’s service life.

Flexibility Enhances Operational Stability

Compared to rigid pipelines, the hose assembly (part number 803432820) possesses excellent flexibility and vibration resistance. When operating an XCMG XE2000 excavator, the frequent and large-amplitude movements of the boom, stick, bucket, and other working devices can cause significant displacement and vibration in the piping. This hose assembly, with its excellent flexibility, can adapt to the equipment’s movements, effectively absorbing vibration energy and reducing stress concentration caused by rigid connections in the piping, thus lowering the risk of loose joints and pipe rupture. Simultaneously, its precise elastic deformation control ensures that excessive stretching or twisting does not occur throughout the entire range of the equipment’s movement, guaranteeing the continuity and stability of fluid transmission, thereby improving the overall reliability of the machine.

Strict Quality Control Ensures Durability

XCMG maintains strict quality control over core components throughout the entire production process. The hose assembly (part number 803432820) undergoes rigorous testing from raw material procurement to finished product delivery. Key indicators such as the oil resistance of the inner rubber layer, the strength of the reinforcing steel wire, and the wear resistance of the outer rubber layer have all been verified through professional laboratory testing. During production, each process is equipped with online quality monitoring to ensure secure joint pressing and reliable sealing. The finished hose assembly also undergoes rigorous testing, including pressure resistance testing, burst testing, and bending fatigue testing, to ensure no leakage or damage under extreme operating conditions. This comprehensive quality control system gives the hose assembly an exceptionally long service life, significantly reducing equipment maintenance and replacement frequency, minimizing downtime, and lowering overall operating costs for users.

Choosing the XCMG XE2000 excavator hose assembly (part number 803432820) means choosing safe and reliable flexible power transmission and long-lasting stable operational support. As an important component of XCMG’s high-quality parts system, it will provide continuous flexible power transmission for your XE2000 excavator during high-intensity operations, facilitating efficient project progress. For more product parameters, procurement channels, or technical support, please feel free to contact us. Let professional parts safeguard your equipment.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

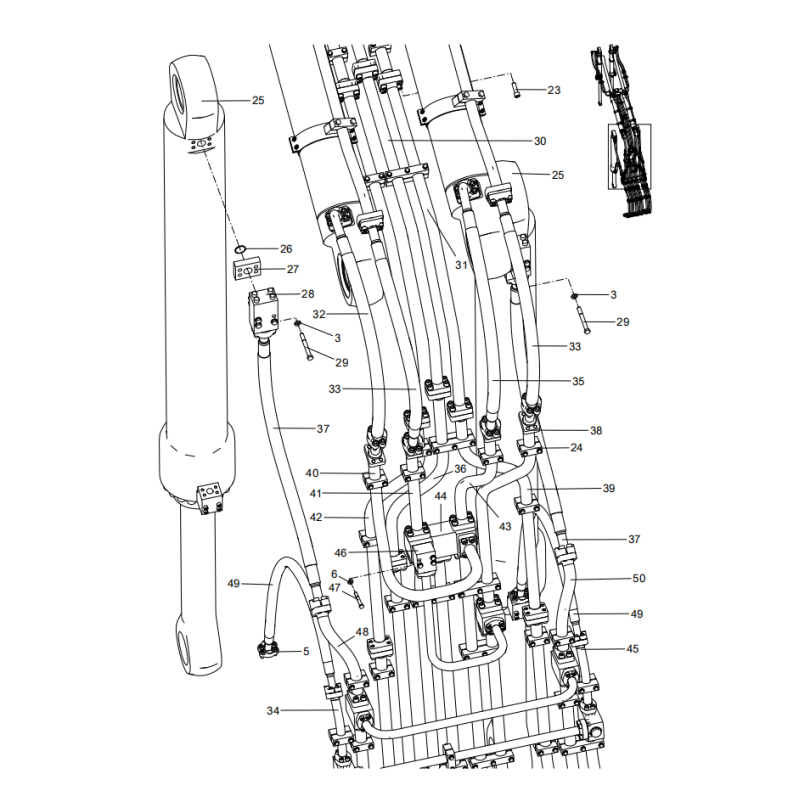

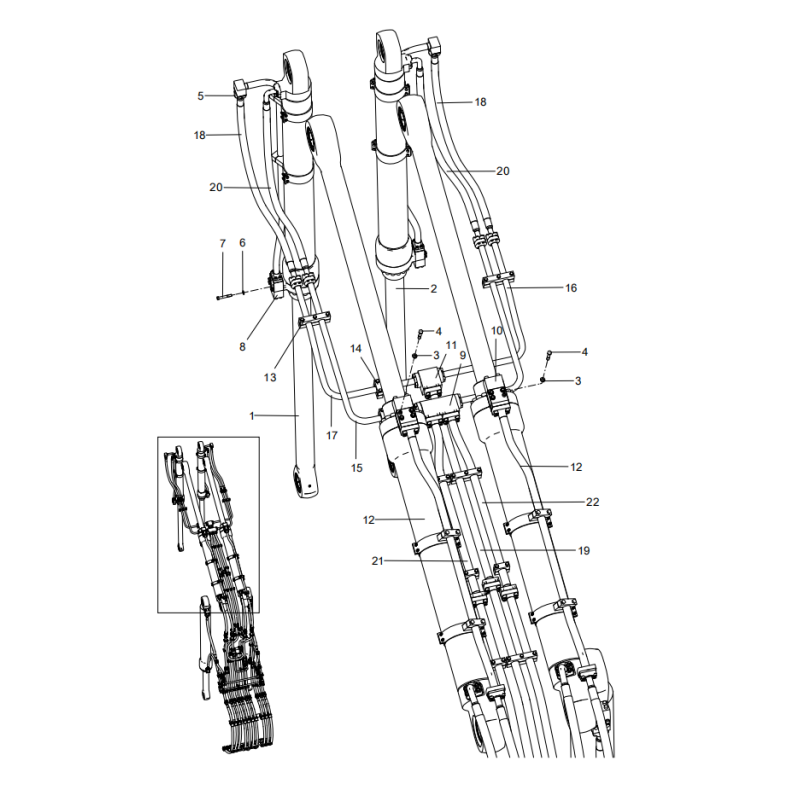

318307969 working device piping

23 805139903 100 SCREW M20×65 GB/T70.1-2008

24 318300994 20 PIPE CLAMP ASSEMBLY

25 804009179 2 BOOM CYLINDER

26 803303446 27 ORING 56.74×3.53-S AS568

27 318305764 2 BLOCK

28 804009189 2 ONE-WAY THROTTLE VALVE

29 805046679 8 BOLT M20×180 GB/T5782-2000

30 318301025 1 STEEL PIPE ASSEMBLY

31 318300998 2 STEEL PIPE ASSEMBLY

32 804421022 1 HOSE ASS’Y

33 813406865 2 HOSE ASS’Y

34 318300983 1 STEEL PIPE ASSEMBLY

35 804421017 1 HOSE ASS’Y

36 318301026 1 STEEL PIPE ASSEMBLY

37 804421024 2 HOSE ASS’Y

38 318300992 1 STEEL PIPE ASSEMBLY

39 318300991 1 STEEL PIPE ASSEMBLY

40 318301028 1 STEEL PIPE ASSEMBLY

41 318301027 1 STEEL PIPE ASSEMBLY

42 318301040 1 STEEL PIPE ASSEMBLY

43 318300993 1 STEEL PIPE ASSEMBLY

44 318301049 1 BLOCK

45 318301041 1 STEEL PIPE ASSEMBLY

46 318301051 1 BLOCK

47 805046670 4 BOLT M16×130 GB/T5782-2000

48 318300982 1 STEEL PIPE ASSEMBLY

49 803432820 2 HOSE ASS’Y

50 318301042 1 STEEL PIPE ASSEMBLY

##