Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803103777 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector (803103777): The Precise Connection Hub of the Circuit System

In the intelligent circuit network of the XE2000 large mining excavator, the connector is the core node for data interaction and power transmission between various electrical modules. Its performance directly affects the overall machine’s control precision and operational safety. XCMG’s original connector (part number: 803103777) is specifically developed for the complex working conditions of this model. With its micro-precision contact technology, military-grade protection capabilities, and deep original factory compatibility, it provides a reliable guarantee for the stable operation of the circuit system under high-intensity mining operations.

Micro-precision contact technology, zero-delay signal transmission

The intelligent control system of the XE2000 excavator relies on real-time communication between multiple sensors and control units, requiring stringent precision in signal transmission. This connector features a pinhole-type micro-precision contact design. The pins are made of high-purity beryllium copper alloy, with a surface roughness ≤0.02μm after nano-gold plating. Contact resistance is stably controlled within 2mΩ, achieving ultra-low loss transmission of electrical signals. The elastic contact structure has been optimized through 20,000 insertion/removal fatigue tests, and with a tolerance of 0.03mm, it maintains continuous and stable contact even under high-frequency vibration conditions, effectively preventing signal interruption and data distortion. Whether it’s hydraulic valve group control commands, engine operating condition feedback, or control panel signal transmission, it achieves millisecond-level response, ensuring an overall improvement in control precision of over 15%.

Comprehensive sealed protection ensures worry-free operation in extreme environments

Dust intrusion, oil immersion, and alternating high and low temperatures in mining operations are major causes of failure in electrical connection components. The 803103777 connector features an integrated metal insert reinforcement structure and a shell made of impact-resistant modified PBT engineering plastic with an impact strength of 22kJ/m², achieving UL94 V0 flame retardant certification. The interface innovatively employs a triple-seal design, incorporating a fluororubber main sealing ring, a silicone rubber dust plug, and a metal locking ring, achieving an IP6K9K protection rating. This fully withstands high-pressure water jets, prolonged oil immersion, and high-concentration dust intrusion. Extreme environment testing has verified stable performance within an ultra-wide temperature range of -45℃ to 130℃, with no rust after 500 hours of salt spray testing. In humid and dusty mining environments, its service life is extended by 75% compared to ordinary connectors, significantly reducing the risk of unplanned downtime.

Fully compatible with original factory parameters, seamless system integration

As a core electrical connection component of the XE2000 excavator, the electrical parameters and mechanical dimensions of this connector have undergone full-process calibration by the original factory. Designed for the 12V/24V hybrid circuit architecture of the entire machine, its rated current reaches 25A, and its insulation withstand voltage is ≥1500V, perfectly matching the power supply and signal transmission requirements of key equipment such as the main controller, sensor clusters, and hydraulic actuators. The connector pin definitions strictly adhere to the SAE J1939 industrial bus standard, with a fitting error between the mounting positioning hole and the device interface ≤0.03mm, enabling rapid and precise assembly without any modifications. Compatibility testing with the entire machine’s circuit system completely avoids signal interference and component burnout caused by parameter mismatches, ensuring efficient and coordinated operation of the circuit system.

Full Lifecycle Quality Control, Multiple Redundancy for Safety Performance

XCMG implements stringent full lifecycle quality control for the 803103777 connector, requiring 22 professional tests from raw material selection to finished product delivery. Each batch of products undergoes vibration testing (10-3000Hz), shock testing (1500G acceleration), and damp heat cycling testing (-40℃ to 85℃, 95% humidity) to ensure structural stability and electrical performance under extreme operating conditions. The products comply with IEC 60529 protection standards and ISO 13407 mining safety specifications, featuring a built-in anti-misconnection mechanical coding structure and overcurrent protection device to effectively prevent short-circuit faults caused by incorrect connections, providing multiple redundancy guarantees for operator and equipment safety.

XCMG XE2000 excavator connector (part number 803103777) – Utilizing micro-precision manufacturing processes to ensure smooth signal transmission, military-grade protection to withstand environmental challenges, and original equipment manufacturer (OEM) compatibility to ensure system compatibility, it is an indispensable and precise connection hub for the electrical systems of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

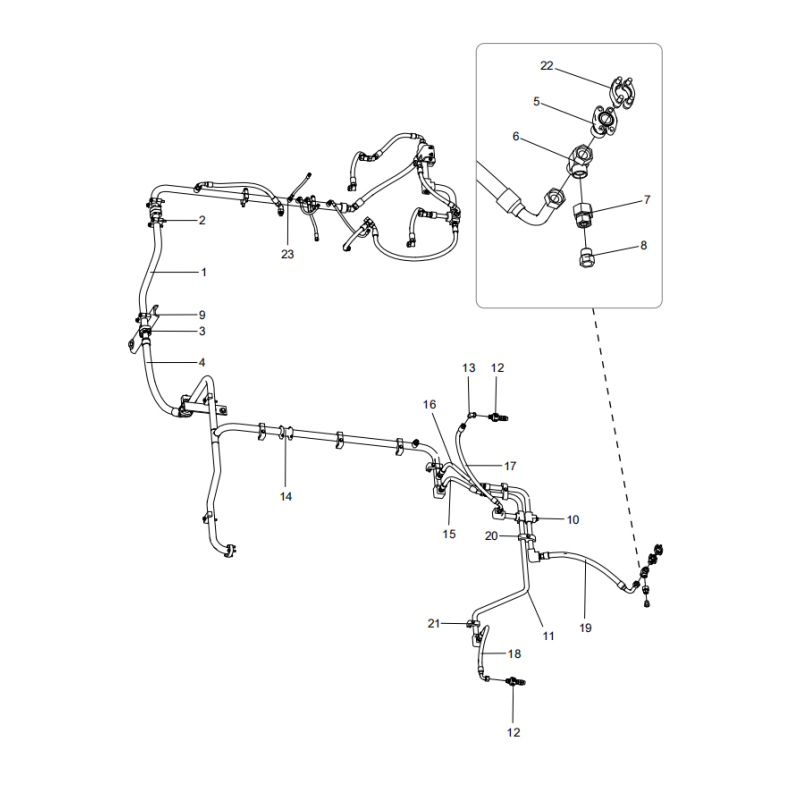

318307823 drain oil pipeline

1 318307798 1 STEEL PIPE ASSEMBLY

2 318006991 1 PIPE CLAMP ASSEMBLY

3 803164240 1 FLANGE ASSEMBLY

4 804414138 1 HOSE ASS’Y

5 803164697 1 BLIND FLANGE

6 803103777 1 CONNECTOR

7 803131927 1 CONNECTOR

8 803150690 1 CONNECTOR

9 318307802 1 PIPE CLAMP ASSEMBLY

10 318307822 1 STEEL PIPE ASSEMBLY

11 318307821 1 STEEL PIPE ASSEMBLY

12 318307819 2 CONNECTOR ASSEMBLY

13 803100741 1 CONNECTOR

14 318307815 1 STEEL PIPE ASSEMBLY

15 803382159 1 HOSE ASS’Y

16 803194411 1 HOSE ASS’Y

17 804414141 1 HOSE ASS’Y

18 803281494 1 HOSE ASS’Y

19 804414139 1 HOSE ASS’Y

20 318307812 2 CLAMP ASSEMBLY

21 318307811 1 PIPE CLAMP ASSEMBLY

22 803164234 1 FLANGE ASSEMBLY

23 318307808 1 MAIN PUMP OIL DRAIN PIPELINE

##