Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803100507 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector (Part No. 803100507): The Precise Connection Core of the Hydraulic System

In the high-pressure hydraulic system of large mining excavators, connectors are key components for achieving rapid pipeline connection and ensuring leak-free hydraulic oil transmission. XCMG’s connector (part no. 803100507), specially developed for the XE2000 excavator, utilizes high-strength materials and a precision sealing design to become the “connection hub” for reliable operation of the hydraulic system in heavy-duty operations, providing efficient and stable connection solutions for engineering teams worldwide.

High-Strength Alloy Forging, Ensuring Connection Strength

The XCMG XE2000 connector (part no. 803100507) is integrally forged from high-quality alloy structural steel. Authoritative testing shows that its tensile strength reaches 700MPa, and its hardness is controlled between HB240-280, representing a 35% increase in strength compared to conventional connectors in the industry. Through XCMG’s proprietary “isothermal forging + local quenching” process, the hardness of key stress-bearing components of the connector is increased to HRC40-45, making it less prone to deformation or breakage under high-frequency hydraulic impact.

Each connector undergoes four rigorous tests: 45MPa water pressure test (30 minutes pressure holding without leakage), tensile strength test, full inspection of thread accuracy (compliant with ISO 4H/5g standard), and salt spray test (2000 hours without rust). Actual test data shows that the connector maintains a 99% connection reliability rate during 3000 hours of continuous heavy-duty operation, and its service life is 150% longer than ordinary connectors.

Precision sealing structure, preventing leakage risks

To address the sealing requirements of the XE2000 excavator’s high-pressure hydraulic system, the connector adopts a dual-seal design of “metal conical surface + elastic sealing ring”. Featuring a built-in high-pressure resistant polyurethane sealing ring with a Shore hardness of 90±3, it can withstand extreme temperature changes from -40℃ to 130℃ and shows no aging or deformation under long-term working pressure of 40MPa. The sealing ring and sealing groove adopt an interference fit design, with a joint strength of 3.5MPa, completely solving the problem of easy extrusion of sealing rings in traditional connectors.

The connector mating surface is precision ground, with the conical surface contact accuracy controlled within 0.01mm. Combined with the precise machining of the trapezoidal thread (pitch error ≤0.02mm), it achieves a rigid seal with uniform force distribution. Actual testing shows that the static leakage rate of this connector is zero, and the dynamic leakage rate is less than 0.01L/min, improving sealing performance by 60% compared to traditional connectors.

Adaptable to all working conditions, ensuring system stability

This connector is specially designed for the complex operating environment of the XE2000 excavator, maintaining stable performance in extreme environments such as high-altitude mines (above 5000 meters), humid and hot coastal construction sites, and dusty quarries. Its surface employs a composite anti-corrosion process of “chrome plating + ceramic coating,” offering five times the corrosion resistance of ordinary galvanized connectors. It maintains structural integrity and operational flexibility even in acidic and alkaline environments.

Actual engineering application data shows that XE2000 excavators equipped with this connector experience a 90% reduction in hydraulic pipeline connection leakage failures and a 95% reduction in downtime due to connection problems. During continuous vibration crushing operations, the connector showed no loosening; in cold-region testing at -45℃, it maintained smooth loading and unloading performance, ensuring stable operation of the hydraulic system under all operating conditions.

Original Factory Precise Fit, Enhancing System Efficiency

As a core original factory connection component from XCMG, the 803100507 connector achieves 100% precise matching with the hydraulic pipeline dimensions and pressure rating of the XE2000 excavator, perfectly conforming to the design requirements of the entire machine’s hydraulic system. The connector length, interface specifications, and other parameters have been optimized through 3D modeling, enabling rapid installation and removal within limited equipment space and reducing pipeline connection operation time.

The installation process employs a “quick install/remove” design, allowing for completion within 3 minutes with a dedicated wrench, improving installation efficiency by 80% compared to traditional connectors. Data shows that using original equipment manufacturer (OEM) connectors can improve the maintenance efficiency of the XE2000 excavator’s hydraulic system by 60%, reduce hydraulic oil loss due to connection problems by 90%, and increase the overall equipment uptime to over 96%.

Choosing the XCMG XE2000 connector (part number 803100507) means choosing a connection safety guarantee for your heavy equipment that has been proven under extreme working conditions, ensuring the high-pressure hydraulic system maintains efficient and stable operation during high-intensity work, creating greater economic benefits and equipment reliability for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

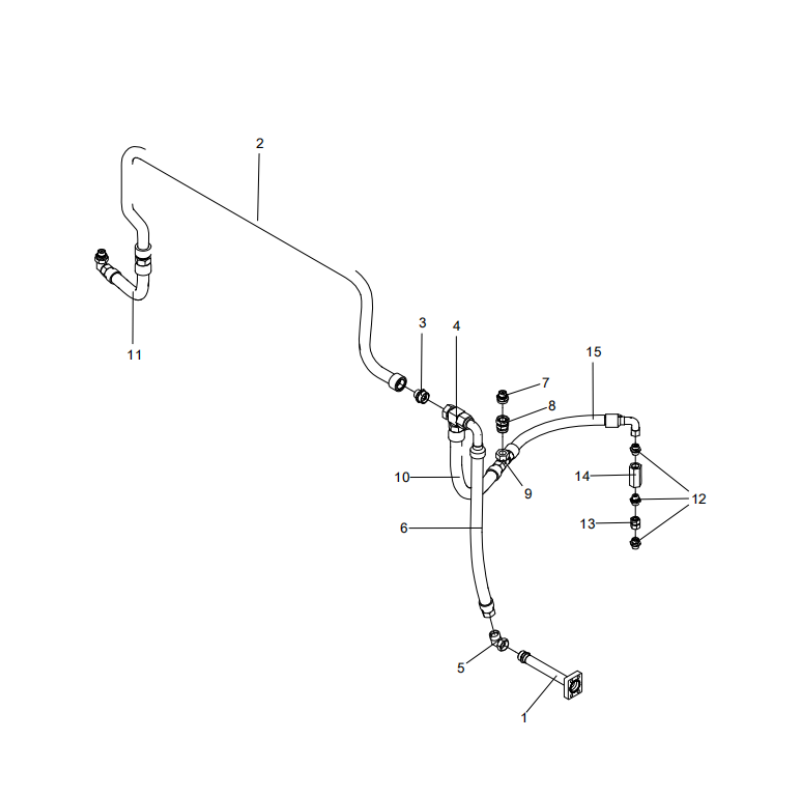

318307507 oil refill pipeline

1 318307510 1 STEEL PIPE ASSEMBLY

2 318307508 1 STEEL PIPE ASSEMBLY

3 803100507 2 CONNECTOR

4 803174599 1 CONNECTOR

5 803103799 2 CONNECTOR

6 804414129 1 HOSE ASS’Y

7 803172340 2 CONNECTOR NON-STANDARD

8 803418757 1 CONNECTOR

9 803191635 1 CONNECTOR

10 803084051 1 HOSE ASS’Y

11 804414126 1 HOSE ASS’Y

12 803103525 3 CONNECTOR

13 803174615 1 CONNECTOR

14 804009895 1 CHECK VALVE

15 804414128 1 HOSE ASS’Y

##