Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

801102881 o-ring 42.5×3.55 XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator O-ring (801102881): A Hydraulic Seal Core with Dimensions of 42.5×3.55

In the complex hydraulic system of the XE2000 large mining excavator, small sealing components often determine the overall operational efficiency of the equipment. XCMG has specially developed an O-ring (specification: 42.5×3.55, part number: 801102881) for this model, which, with its extremely precise manufacturing process and weather resistance, provides a reliable guarantee for the sealing of hydraulic pipelines and components.

Ultra-precise dimensional tolerances create a gapless sealing interface

The leak-proof effect of the hydraulic system begins with precise dimensional matching. This O-ring is machined using imported German precision molds, and the dimensional tolerance of the 42.5mm outer diameter and 3.55mm wire diameter is strictly controlled within ±0.02mm, far exceeding the industry standard. After installation, it achieves a micron-level fit with the sealing groove. Under hydraulic pressure, it forms a complete sealing ring through uniform elastic deformation, effectively preventing hydraulic oil leakage in critical parts such as high-pressure pipeline joints and valve components. This avoids power loss, oil contamination, and premature wear of components caused by leakage at the source.

Oil- and temperature-resistant material, resisting harsh operating conditions

The high temperatures, oil contamination, and continuous vibrations in mining environments place extremely high demands on the material stability of seals. The 801102881 O-ring uses high-purity oil-resistant nitrile rubber as its base material, treated with XCMG’s patented vulcanization process to form a dense and stable molecular structure. It maintains excellent elasticity in an extreme temperature range of -40℃ to 130℃ and has superior resistance to swelling from media such as mineral hydraulic oil and gear oil. Actual test data shows that under the high-intensity operating conditions of the XE2000 (16 hours per day), the service life of this O-ring is more than 50% longer than that of ordinary seals, significantly reducing the frequency of downtime replacement.

Original factory parameter compatibility ensures coordinated system operation

As a core original XCMG component, this O-ring precisely matches the key parameters of the XE2000 hydraulic system. Designed for the machine’s 35MPa working hydraulic pressure, its rubber compound is specially reinforced, maintaining excellent elastic recovery under long-term high pressure to prevent permanent deformation and seal failure. Simultaneously, it is perfectly compatible with the sealing groove dimensions of core components such as the hydraulic pump, multi-way valve, and boom cylinder, eliminating the risk of leakage caused by dimensional deviations of non-original parts and ensuring the hydraulic system always operates at high efficiency.

XCMG XE2000 excavator O-ring (42.5×3.55, part number 801102881) – With ultra-precise dimensions to build a strong sealing defense, weather-resistant materials to withstand extreme working conditions, and original factory compatibility to ensure system safety, it is an indispensable sealing guardian for the hydraulic system of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

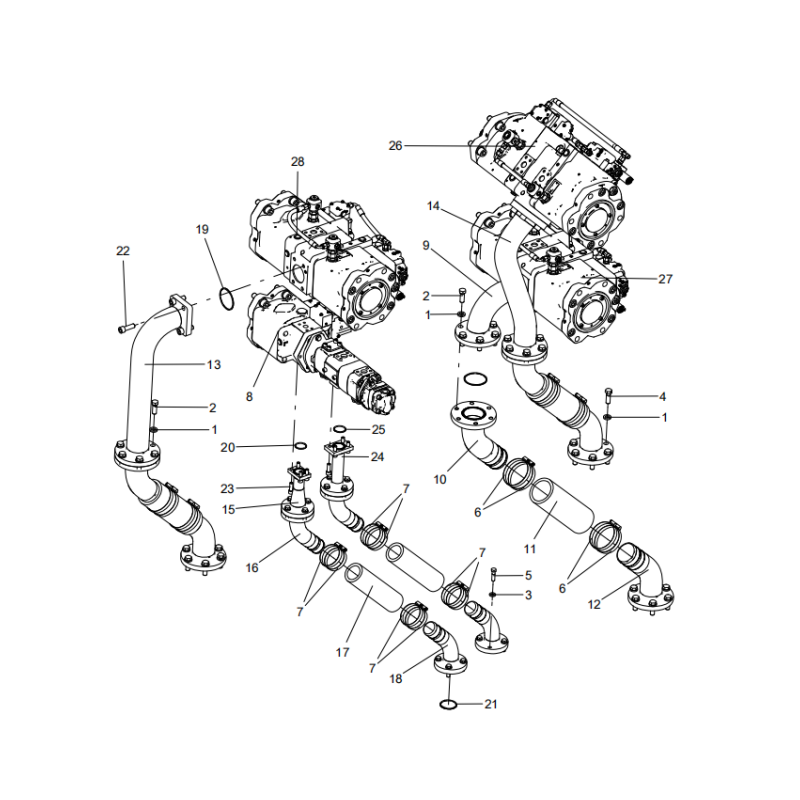

318307325 pump oil suction pipeline

1 329900304 36 THICKENED FLAT WASHER

2 805047646 18 BOLT M16×45 GB/T5782-2000

3 329900303 16 THICKENED FLAT WASHER

4 805011131 18 BOLT M16×50 GB/T5782-2000

5 805049511 16 BOLT M12×45 GB/T5782-2000

6 800161669 12 HOSE CLAMP

7 800161637 8 HOSE CLAMP

8 318307470 1 COOLING PUMP GEAR PIMP MOUNTING

9 318307317 1 STEEL PIPE ASSEMBLY

10 318307310 3 STEEL PIPE ASSEMBLY

11 318307321 3 OIL SUCTION HOSE

12 318307320 3 STEEL PIPE ASSEMBLY

13 318307316 1 STEEL PIPE ASSEMBLY

14 318307318 1 STEEL PIPE ASSEMBLY

15 318307315 1 STEEL PIPE ASSEMBLY

16 318307323 2 STEEL PIPE ASSEMBLY

17 318307313 2 OIL SUCTION HOSE

18 318307312 2 STEEL PIPE ASSEMBLY

19 801134077 9 ORING 85×3.55 GB/T3452.1-2005

20 803174967 1 ORING 40×3.55 GB/T3452.1-2005

21 803192098 4 ORING 60×3.55 GB/T3452.1-2005

22 805139896 12 SCREW M16×50 GB/T70.1-2008

23 805139869 8 SCREW M12×35 GB/T70.1-2008

24 318307311 1 STEEL PIPE ASSEMBLY

25 801102881 1 ORING 42.5×3.55 GB/T3452.1-2005

26 318307467 1 MAIN PUMP I MOUNTING

27 318307469 1 MAIN PUMP II MOUNTING

28 318307468 1 MAIN PUMP III MOUNTING

##