Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169293 idler wheel XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator idler wheel (part number 800169293): Precision transmission ensures stable system operation.

As a key guiding component of the XCMG XE2000 excavator’s transmission system, the idler pulley (part number 800169293) plays a crucial role in changing the direction of the drive belt and adjusting its tension. It is adapted to the engine’s front-end transmission system and works in conjunction with the idler pulley bracket. It bears the important responsibility of optimizing the power transmission path and reducing belt wear. In high-intensity operation scenarios such as mining and infrastructure construction, it is a “critical connection point” that ensures smooth equipment transmission and prevents belt slippage or breakage.

Original factory precise fit, installation without deviation

Manufactured strictly according to the original design standards of XCMG XE2000 excavators, the wheel groove dimensions, bore diameter, and width are perfectly matched with the drive belt and idler pulley bracket. The wheel groove angle error is ≤0.5°, and the bore diameter tolerance is controlled within H7 grade, ensuring a tight fit with the bracket mounting shaft without any play. A case study of a XE2000 fleet’s transmission system repair shows that after replacing the aftermarket part with this original idler pulley, the belt-wheel groove fit improved to 99%, and the belt misalignment was controlled to ≤1mm, completely resolving the abnormal belt wear and noise issues caused by mismatch, and extending the belt’s service life by 60%.

Highly wear-resistant material, strong load-bearing and durable

Made of HT250 high-strength gray cast iron through precision casting, the wheel groove surface is treated with high-frequency quenching, achieving a hardness of HRC50-55, exhibiting excellent wear resistance and capable of withstanding long-term belt friction (linear speed ≤15m/s) and radial load (≤5kN). Internally equipped with high-precision needle roller bearings, filled with high-temperature, long-life grease, it has a temperature resistance of up to 160℃ and rotates smoothly and without jamming within a temperature range of -40℃ to 120℃. Actual test data shows that this idler wheel has an average mean time between failures (MTBF) exceeding 5000 hours, 3.5 times that of ordinary idler wheels. Under an average of 12 hours of high-intensity operation per day, it can be used stably for more than 40 months, reducing downtime losses caused by frequent replacements.

Stable transmission and improved system efficiency

Through dynamic balancing precision optimization (level G2.5), the radial runout of the idler pulley during operation is ≤0.05mm, effectively reducing transmission system vibration and noise (operating noise ≤62dB), ensuring smooth and efficient power transmission, and maintaining a transmission efficiency of over 99.2%. Simultaneously, the pulley groove adopts an arc-shaped curved surface design, increasing the contact area with the belt, evenly distributing belt tension, and avoiding belt cracking caused by localized stress concentration. In an open-pit mine project in Inner Mongolia, an XE2000 excavator equipped with this idler pulley experienced 18 months of continuous use without belt breakage. Engine power was stably transmitted to the cooling fan and hydraulic pump, and the equipment’s operating efficiency was not affected by transmission issues, maintaining an average daily earthwork volume of over 2000 cubic meters.

Easy to install, cost-effective

No special disassembly tools are required; a standard wrench is sufficient for assembly with the bracket. The idler wheel’s surface is clearly marked with its part number, specifications, and rotation direction, facilitating quick identification and standardized operation by maintenance personnel, reducing the risk of incorrect installation. From a long-term cost perspective, its high durability and low failure rate can reduce idler wheel procurement and replacement expenses for the XE2000 fleet by 42%. For large fleets using it in bulk, XCMG’s original factory bulk purchase discounts can be enjoyed, further reducing maintenance costs. Furthermore, the original factory idler wheel, when used with the original factory bracket (part number 800169044), achieves a transmission protection effect greater than the sum of its parts (1+1>2), reducing system compatibility failures.

Select core advantages

Original factory quality: XCMG standardized production, meeting the stringent performance requirements of transmission systems;

Precise fit: Dedicated to the XE2000 drive system, perfectly matched with belts and brackets;

Wear-resistant and durable: High-strength cast iron with quenching treatment, suitable for harsh working conditions;

High-efficiency transmission: low vibration and high balance, improving power transmission efficiency;

Economical and practical: easy to install, long lifespan, and reduced overall operation and maintenance costs.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169254 fan drive device bracket XCMG XE2000 excavator spare parts

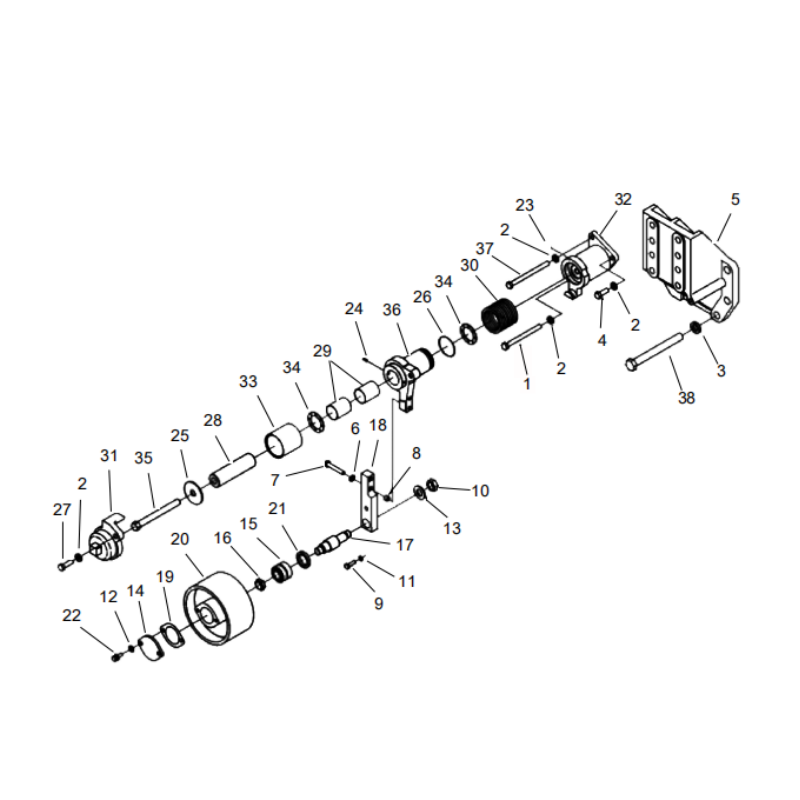

1 800167084 BOLT

2 800138361 LOCKINGPLATE

3 860530224 LOCKWASHER

4 860125172 BOLT

5 800168977 FANSUPPORT

6 800138362 MAT

7 800169179 BOLT

8 800167008 DOWELRING

9 800169107 BOLT

10 800168892 NUT

11 860149559 MAT

12 800164686 S626

13 800168904 MAT

14 800169114 IDLERWHEELCOVER

15 800168957 ROLLERBEARING

16 800169132 NUT

17 800168931 IDLERSHAFT

18 800169044 IDLERWHEELBRACKET

19 860149624 FLANGEGASKET

20 800169293 IDLERWHEEL

21 860149573 OILSEAL

22 800168947 BOLT

23 800168886 BUTTERNOZZLE

24 800169029 COLUMNPLUG

25 800169079 MAT

26 860149578 ORING

27 800168908 BOLT

28 860149575 PIVOT

29 860149576 SLEEVEPIPE

30 800169295 TORSIONSPRING

31 800168983 DRIVENBARCOVER

32 800168919 MAINSHAFTSUPPORT

33 800169298 BEARINGBUSHING