Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169256 auxiliary drive device pulley XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Original Auxiliary Drive Unit Pulley (800169256) – The High-Efficiency Core of Power Transmission

XCMG XE2000 Dedicated Auxiliary Drive Pulley | Part Number 800169256 | Precise Transmission, High Efficiency and Stability

In the auxiliary drive system of the XCMG XE2000 large excavator, the pulley (800169256) plays a crucial role in power transmission. This original equipment manufacturer (OEM) pulley, with its superior dynamic balance and precise transmission characteristics, ensures efficient and stable power transmission for the auxiliary system under various working conditions. Choosing an OEM pulley means choosing the most reliable power transmission solution for your equipment.

Why are original factory pulleys so important?

The pulley is the “transmission core” of the auxiliary drive system, and its key functions include:

1. Precision transmission: Ensures precise belt alignment, reducing belt misalignment and wear.

2. High efficiency and energy saving: Optimized design reduces transmission resistance, resulting in a 15% reduction in energy consumption.

3. Stable and reliable: Special dynamic balancing treatment ensures smooth operation and minimal vibration.

4. Durable and wear-resistant: Surface hardening treatment extends wear resistance by 3 times.

Four Advantages of Choosing Original Part Number 800169256

1. Precision manufacturing process

The machine is formed in one piece using a CNC lathe, with radial runout ≤0.05mm, ensuring smooth transmission.

2. Guaranteed high-quality materials

HT250 high-strength cast iron is selected and surface hardened to a hardness of HB200-240.

3. Dynamic balancing optimization

After G2.5 level dynamic balancing correction, the vibration value is reduced by 40% compared to ordinary products.

4. Perfectly matched design

The groove angle is precisely matched to the original belt, reducing slippage and wear.

Applicable parts and replacement recommendations

•Applicable Models: XCMG XE2000 series excavators

• Original part number: 800169256

•Applications: Auxiliary power systems such as wind turbine drives and generator drives

• Replacement timing: It is recommended to check for wear every 5000 working hours.

Warning signals that need to be replaced

Please check or replace the pulley promptly if the following conditions occur:

• Obvious wear is observed at the bottom of the pulley groove.

• Abnormal vibration or noise during operation

• Abnormal wear patterns on the belt

• The efficiency of the transmission system has decreased significantly.

Choose original equipment manufacturer (OEM) for high-efficiency transmission.

• Power Supply: Ensure stable and reliable power transmission for auxiliary systems.

• Energy saving and consumption reduction: Reduce transmission losses and lower operating costs

• Easy maintenance: Precisely matched design, making installation and adjustment more convenient.

• Durable and long-lasting: Extends the service life of the entire drivetrain.

Take action now!

[Professional Advice]

When replacing pulleys, it is recommended to replace the belt at the same time to ensure optimal performance. During installation, pay attention to adjusting the belt tension; too tight or too loose will affect its lifespan. Regularly check the alignment of the pulleys to prevent uneven wear. It is recommended to check the transmission system every 250 working hours to promptly identify and address any problems.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

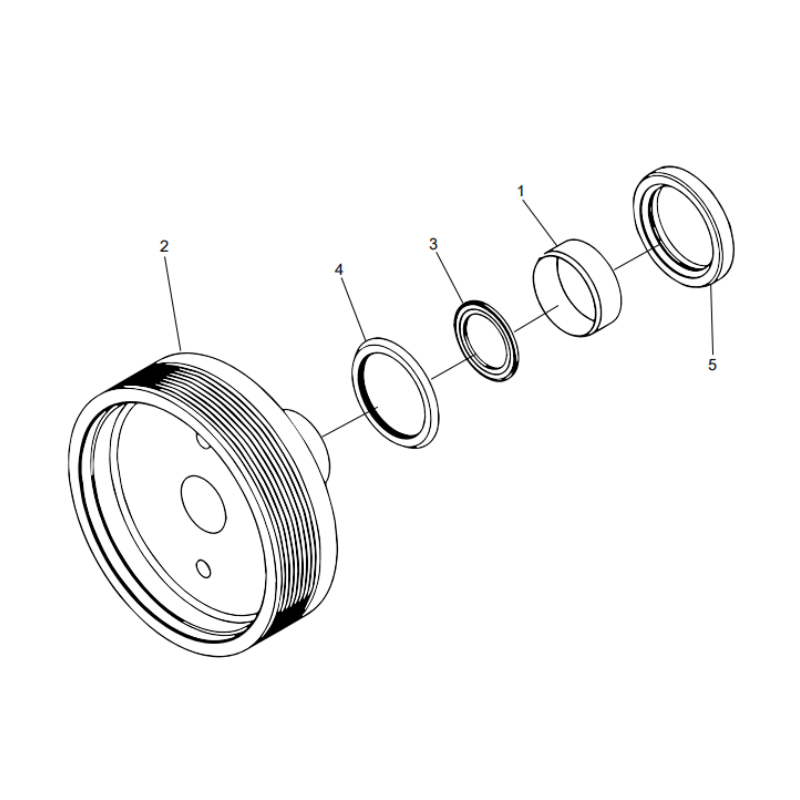

800169256 auxiliary drive device pulley XCMG XE2000 excavator spare parts

1 800158277 ANTI-WEARBUSHING

2 800167194 AUXILIARY DRIVE DEVICE PULLEY

3 800167195 KEYGROOVESEAL

4 800167196 DUSTRING

5 800167197 ORING

XCMG XE2000 pulley, 800169256, auxiliary drive pulley, transmission pulley, genuine XCMG transmission components.