Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169113 washer XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Original Washer (800169113) – The Invisible Guardian of a Robust Connection

XCMG XE2000 Dedicated High-Strength Washer | Part Number 800169113 | Uniformly Distributes Pressure, Prevents Loosening, and Resists Vibration

Among the various connection parts of the XCMG XE2000 large excavator, the washer (800169113), though seemingly a simple component, plays a crucial role in pressure balance. This genuine factory washer, with its precise thickness control and excellent elastic recovery characteristics, ensures that the bolt connection maintains uniform preload even under severe vibration conditions. Choosing genuine factory washers means choosing the most reliable connection protection solution for your equipment.

Why are original factory washers so important?

Washers are the “pressure regulators” of fastening systems, and their core functions include:

1. Pressure distribution: Distribute the bolt preload evenly to the connection surface to avoid stress concentration.

2. Anti-loosening and shock-resistant: Special surface treatment increases friction, improving the anti-loosening effect by 45%.

3. Sealing and leak prevention: Fills in microscopic unevenness on the joint surface to prevent oil leakage.

4. Surface protection: Prevents damage to the surface of the connectors during bolt tightening.

Four Advantages of Choosing Original Part Number 800169113

1. Precision manufacturing process

The material is formed using CNC stamping, with thickness tolerance controlled within ±0.03mm and parallelism error not exceeding 0.05mm.

2. Guaranteed high-quality materials

Selected from 65Mn spring steel, heat-treated to a hardness of HRC40-45, its elastic retention force is increased by 3 times.

3. Surface treatment technology

Phosphating treatment ensures a stable coefficient of friction within the range of 0.10-0.15, providing a long-lasting and reliable anti-loosening effect.

4. Strict quality inspection

Each batch undergoes a 24-hour salt spray test and 500,000 vibration tests, meeting DIN 125 standards.

Applicable parts and replacement recommendations

•Applicable Models: XCMG XE2000 series excavators

• Original part number: 800169113

• Application areas: Key components such as engine mounts, hydraulic pump flanges, and track shoe connections.

• Replacement timing: It is recommended to replace the washer after each disassembly, and replace it immediately if deformation is found during regular inspections.

Warning signals that need to be replaced

Replace the washer immediately if the following conditions occur:

• Indentations or permanent deformation on the gasket surface

• Elasticity fails; the original thickness cannot be restored after being pressed.

• The surface anti-rust layer is damaged or rust has appeared.

• Signs of loosening at the connection points

Choose the original manufacturer for reliable connection.

• Uniform force distribution: Prevents damage to connectors due to concentrated pressure.

• Anti-loosening guarantee: Significantly reduces the risk of bolt loosening.

• Enhanced sealing performance: Improves the sealing performance of connection points.

• Extended lifespan: Protects connection surfaces and extends equipment lifespan.

Take action now!

[Professional Advice]

During installation, ensure the washers and bolts are compatible to avoid mismatch. It is recommended to replace the washers with new ones after each disassembly; do not reuse them. Store in a dry environment to prevent damage to the surface treatment layer. During regular inspections, carefully observe the condition of the washers and replace any faulty parts promptly. Use a torque wrench to tighten to the standard value, ensuring accurate preload.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169244 front-gear drive-system auxiliary drive XCMG XE2000 excavator spare parts

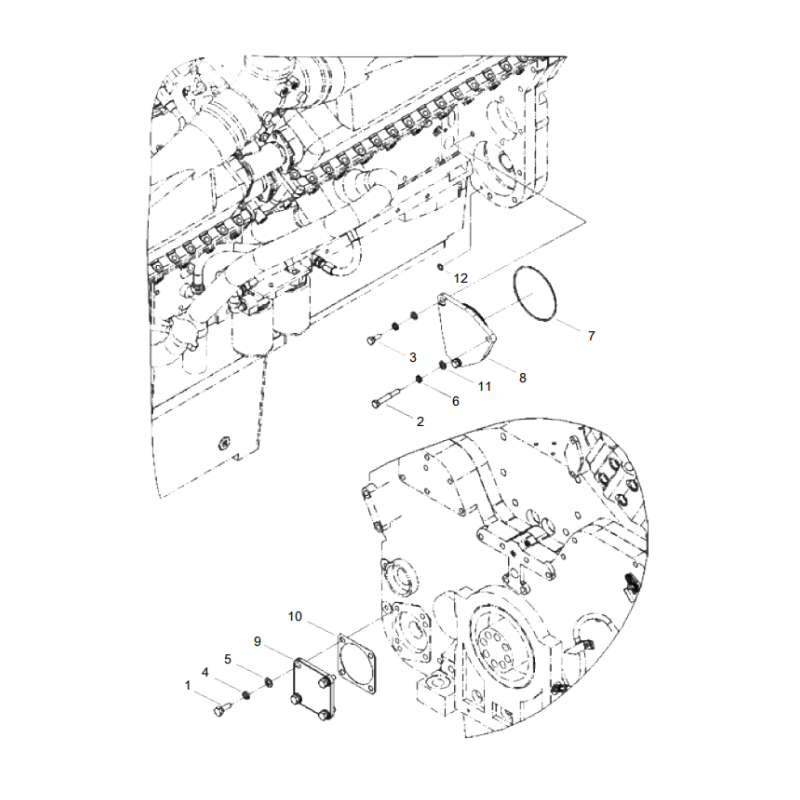

1 800168958 BOLT

2 800169101 BOLT

3 800167065 HEXAGONSCREW

4 800169113 WASHER

5 800169075 WASHER

6 800169180 WASHER

7 800158325 ORING

8 860149587 HYDRAULICPUMPBLINDFLANGE

9 800168946 BLINDFLANGE

10 800167063 GASKETFORHANDHOLE

11 800168926 WASHER

12 800142725 ORING

XCMG XE2000 washers, 800169113, high-strength washers, anti-loosening washers, genuine XCMG fasteners