Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169075 washer XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Washer 800169075 | Original factory fit, anti-loosening and vibration damping, sealing and wear-resistant, ensuring stable bolt tightening

In high-intensity operations such as hard rock excavation in mining and heavy-duty construction, critical bolt connections on the XCMG XE2000 excavator, including the boom-to-frame connection, hydraulic valve assembly, and engine compartment component assembly, rely on washers for pressure distribution and anti-loosening sealing. If these washers fail, bolts can easily loosen, contact surfaces can wear, or fluid leakage may occur. The XCMG XE2000 original factory washer (part number 800169075), as a core auxiliary component for bolt tightening, can tightly conform to the surface of the bolt and the connected parts, preventing connection failures caused by pressure concentration and vibration, thus building a solid “buffer layer” for the stable connection of critical parts of the XE2000 excavator.

800169075 Washer: Three core advantages, compatible with XE2000

Original factory precision fit: The dimensions strictly adhere to the XCMG XE2000 bolt connection design standard. The inner and outer diameter tolerances (±0.05mm) and thickness accuracy (±0.02mm) are perfectly matched with matching bolts such as 800168958, allowing for direct assembly without cutting or grinding. The washer surface undergoes precision grinding (flatness error ≤0.01mm), perfectly fitting the bolt head and the surface of the connected part. This avoids uneven force and excessive gaps caused by misfitting the washer, making it compatible with bolt fastening needs in various scenarios such as booms, hydraulic pumps, and cab frames, ensuring a stable “three-in-one” connection between the washer, bolt, and connected part.

Strong anti-loosening, vibration damping, and sealing: Adopting a composite structure design—a metal substrate (Q235 low carbon steel) provides rigid support, with an oil-resistant rubber coating (thickness 0.1-0.2mm) on the surface; the rubber coating has a compression rebound rate of ≥90%, which can absorb residual stress and operational vibration after bolt tightening, with a vibration attenuation rate of ≥35%, and can withstand high-frequency vibration of 1800 times/minute without failure, effectively preventing bolt loosening; at the same time, the rubber coating can fill the tiny gaps on the contact surface, forming a sealing barrier at the bolt connection, blocking mine dust, construction site rainwater and hydraulic oil leakage, and preventing corrosion or fluid intrusion from the surface of the connecting parts.

Wear-resistant, corrosion-resistant, and long-lasting: The metal substrate surface adopts a hot-dip galvanizing + passivation dual protection process (coating thickness ≥8μm), with a salt spray resistance test of over 400 hours, which can resist the corrosion of moisture, dust and chemical media, and avoid contact surface jamming caused by gasket corrosion; the rubber coating adopts an oil-resistant and aging-resistant formula, maintaining elasticity in a temperature range of -40℃ to 120℃, without hardening or cracking, and is suitable for high-temperature environments in engine compartments and low-temperature operating scenarios in northern winters; the overall service life exceeds 10,000 hours (80% longer than ordinary flat washers), reducing the cost of bolt re-tightening or replacement due to gasket wear and aging.

Suitable for multiple scenarios, with traceable quality, and safe to use.

Whether the XE2000 is operating in hard rock mining (high vibration, high dust conditions), heavy-duty earthmoving operations in infrastructure (continuous high loads), or in humid, rainy, and fluctuating outdoor environments, the 800169075 washer consistently performs its auxiliary fastening function. Each washer undergoes XCMG’s triple testing (dimensional accuracy calibration, anti-loosening performance test, and salt spray resistance test), conforming to the ISO 7089 flat washer standard and engineering machinery fastening auxiliary component specifications. Official traceability is supported (authenticity can be verified by scanning the anti-counterfeiting code on the packaging), ensuring safe and trouble-free use and preventing accidents such as bolt loosening and component damage caused by the breakage or deformation of inferior washers.

Select 800169075, XE2000 bolt connection.

If you encounter issues such as loose bolt connections, worn contact surfaces, or fluid leakage on your XCMG XE2000 machine, or need to replace aged or deformed washers, the 800169075 original factory washer is the best choice. It provides reliable anti-loosening, vibration damping, and sealing performance, ensuring long-term stability of bolt connections, reducing component wear and maintenance frequency, and helping the XE2000 maintain high-efficiency operation under various high-intensity working conditions, thus facilitating the smooth progress of engineering tasks.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169244 front-gear drive-system auxiliary drive XCMG XE2000 excavator spare parts

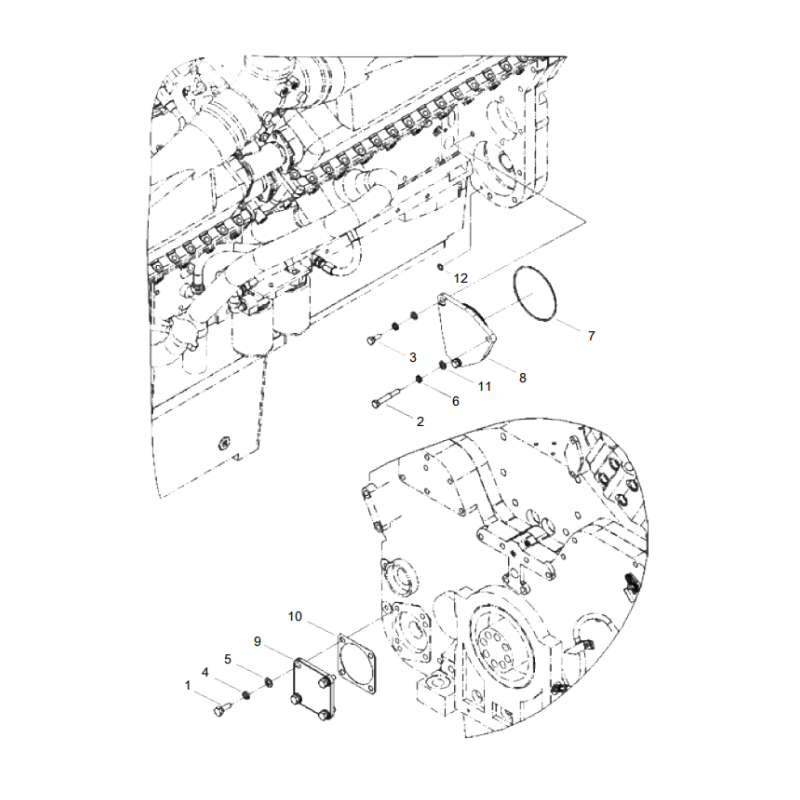

1 800168958 BOLT

2 800169101 BOLT

3 800167065 HEXAGONSCREW

4 800169113 WASHER

5 800169075 WASHER

6 800169180 WASHER

7 800158325 ORING

8 860149587 HYDRAULICPUMPBLINDFLANGE

9 800168946 BLINDFLANGE

10 800167063 GASKETFORHANDHOLE

11 800168926 WASHER

12 800142725 ORING

XCMG XE2000 excavator washers

800169075 Washer

XCMG XE2000 Original Washers

800169075 Original factory fastening auxiliary parts

Excavator anti-loosening washers

XCMG XE2000 Bolt Loosening Solution

Vibration-damping sealing excavator gaskets

Composite structure wear-resistant gasket

XE2000 Excavator Boom Connecting Washer

800169075 Excavator parts

Mining operation fastening washers

Infrastructure heavy-duty excavator washers

Anti-corrosion gaskets for construction machinery

XCMG XE2000 hydraulic pump mounting washers

High and low temperature resistant excavator gaskets