Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169071 crankshaft belt pulley XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Crankshaft Pulley (Part No. 800169071): The Precision Transmission Core for Power Distribution

The XCMG XE2000 mining excavator, with an operating weight of 192,000 kg, an 810 kW imported engine, and a large bucket capacity of 10-14 m³, continuously delivers powerful output in heavy-duty mining operations worldwide. The crankshaft pulley (part no. 800169071), as a key component for engine power distribution, is a crucial transmission hub connecting the crankshaft and auxiliary systems, directly affecting the stability of the overall machine’s power distribution and the collaborative efficiency of the auxiliary systems.

This crankshaft pulley is precision-cast from high-strength gray cast iron, combined with metal strengthening technology, possessing excellent structural rigidity and fatigue resistance. Facing the centrifugal force generated by the high-speed rotation of the engine crankshaft and the radial tension of the belt drive, it maintains a stable structural shape, effectively resisting deformation or cracks caused by long-term operation, avoiding power transmission interruptions due to pulley failure, and continuously providing power support to the auxiliary systems. In terms of design, it was specifically developed based on the crankshaft parameters and transmission requirements of the XE2000 engine. The pulley groove size, diameter accuracy, and balance have been precisely calibrated. An optimized belt groove design ensures perfect meshing with the drive belt, reducing slippage and energy loss. Precise dynamic balancing reduces vibration amplitude during high-speed operation, minimizing additional impact on the crankshaft and improving engine smoothness.

Utilizing XCMG’s advanced manufacturing processes, this crankshaft pulley undergoes rigorous precision testing and performance evaluation. The surface is precision machined and balanced, with radial runout controlled within 0.05mm to ensure transmission stability. High-temperature aging treatment eliminates casting stress, improving structural stability and preventing deformation after long-term use. The pulley groove surface is hardened to enhance wear resistance and extend the service life of the belt connection.

The performance of the crankshaft pulley directly affects the operating efficiency of the engine’s auxiliary systems. It drives key auxiliary components such as generators, water pumps, and air conditioning compressors to operate synchronously through stable power transmission, ensuring the normal operation of the engine’s power generation, cooling, and air conditioning systems. The precise transmission ratio design ensures that each auxiliary system operates at optimal parameters, improving overall engine efficiency and reducing energy loss. Simultaneously, stable transmission performance reduces belt wear and loosening, lowering the risk of auxiliary system failures.

Choosing the XCMG XE2000 excavator crankshaft pulley (part number 800169071) not only provides you with a high-quality power distribution component that offers precise transmission and durability, but also allows you to leverage XCMG’s global service network for timely parts supply and professional technical support. Let this precise power distribution transmission core strengthen the power distribution defense of your mining equipment’s engine system, ensuring uninterrupted high-efficiency production.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169284 damper XCMG XE2000 excavator spare parts

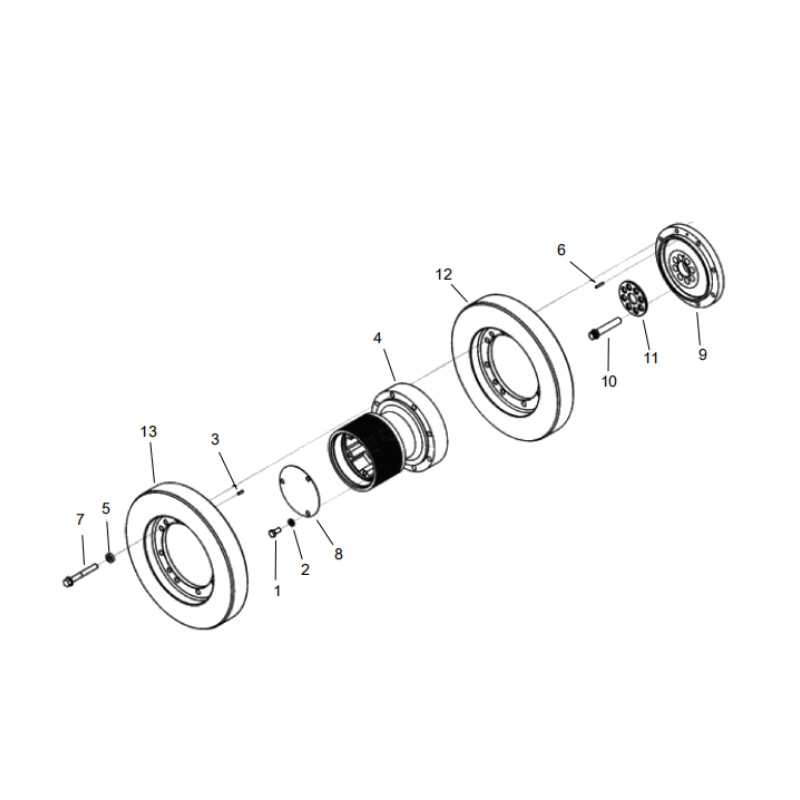

1 800168997 3 BOLT

2 800167052 3MAT

3 800144926 1 ROLLING NEEDLE

4 800169071 1 CRANKSHAFT BELT PULLEY

5 800167053 8MAT

6 800167055 1 ROLL PIN

7 800167056 8 BOLT

8 800167057 1 PROTECTION COVER

9 800167058 1 CRANKSHAFT ADAPTER

10 800167059 8 BOLT

11 800167060 1 CRANKSHAFT GASKET

12 800168975 1 VISCOUS DAMPING ABSORBER

13 800167062 1 VISCOUS DAMPING ABSORBER