Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169034 plug XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Plug 800169034 | Original factory fit, leak-proof, corrosion-resistant and durable, ensuring cleanliness of the fluid system.

The hydraulic lines, engine oil passages, and coolant chambers of the XCMG XE2000 excavator often require plugs for sealing—to prevent fluid leakage and block the intrusion of dust and impurities. The XCMG XE2000 original plug (part number 800169034), as a core sealing component, precisely matches the equipment’s opening specifications, eliminating fluid loss and system contamination caused by seal failure, thus building a solid “protective barrier” for the clean and stable operation of the XE2000 excavator’s fluid system.

800169034 End Cap: Three Core Advantages, Compatible with XE2000

Original factory precise fit: The dimensions strictly follow the XCMG XE2000 fluid system opening design standard. The thread specifications (tooth profile and pitch accuracy up to 5g level), head structure, and sealing surface dimensions are completely matched with the equipment interface. It can be directly tightened without cutting or adjustment, avoiding sealing gaps and installation misalignment caused by adaptation deviations. It is compatible with the sealing requirements of various fluid media such as hydraulic oil and coolant, ensuring a seamless fit with pipelines and cavities.

High-efficiency sealing to prevent leakage and contamination: The sealing surface is precision machined (flatness error ≤0.02mm), and is equipped with original sealing rings (or has its own sealing texture). It can withstand a system pressure of 2.5MPa, effectively preventing hydraulic oil and coolant leakage, while preventing outdoor dust, rainwater and moisture from entering the cavity. This avoids valve assembly jamming and component wear caused by fluid contamination and maintains the cleanliness of the system.

Corrosion resistant, durable and long service life: Made of brass (or corrosion resistant alloy), with surface passivation treatment, it has passed salt spray test for over 400 hours, resisting fluid corrosion, mining dust erosion and the effects of humid construction site environments, and is not prone to rust, deformation or thread stripping; it maintains structural stability in a temperature range of -30℃ to 120℃, with a service life of over 6000 hours (70% longer than ordinary carbon steel plugs), reducing frequent maintenance and downtime costs caused by plug failure.

Suitable for multiple scenarios, with traceable quality, and safe to use.

Whether the XE2000 is operating under high-intensity mining conditions, heavy-duty infrastructure work, or in humid and rainy outdoor environments, the 800169034 plug consistently delivers a reliable seal. Each plug undergoes triple testing by XCMG (sealing performance test, dimensional accuracy calibration, and corrosion resistance test), conforming to the ISO 12151 fluid system plug standard and engineering machinery sealing component specifications. Official traceability is supported, ensuring safe and trouble-free use and preventing system failures and operational accidents caused by leaks from inferior plugs.

Select 800169034, protect XE2000 fluid seal.

If you are experiencing pipeline leaks, dust ingress into the cavity, or need to replace aging or corroded plugs on your XCMG XE2000 system, the original factory plug (800169034) is the best choice. It provides reliable sealing performance to ensure a clean and stable fluid system, reduces component wear and maintenance frequency, helps the XE2000 operate efficiently under various conditions, and facilitates the smooth progress of engineering tasks.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169250 driver’s cab heater pipe XCMG XE2000 excavator spare parts

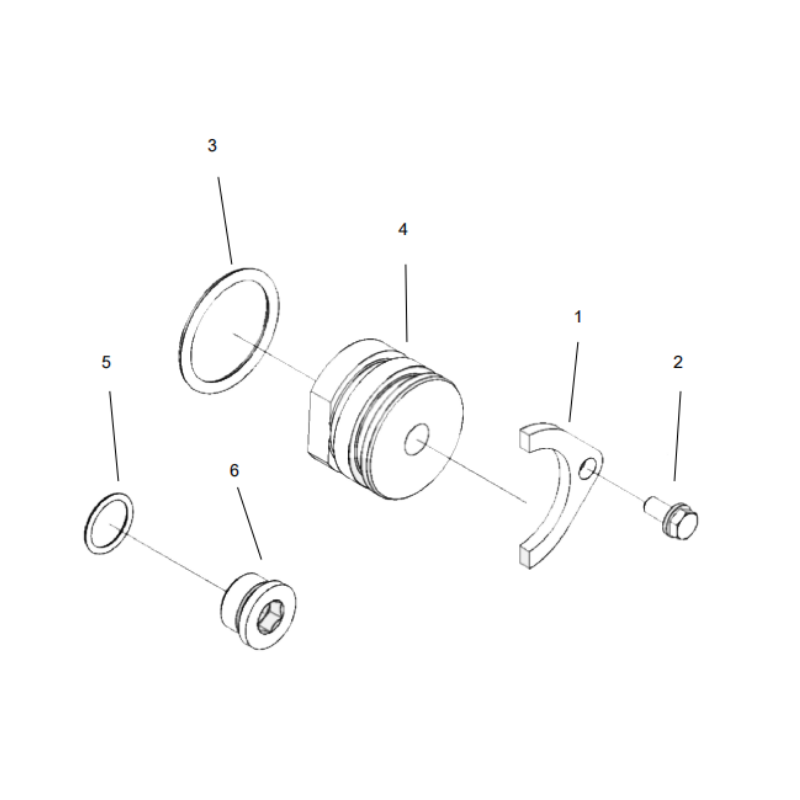

1 800169076 FIXATION CLAMP

2 800167164 BOLT

3 800166575 ORING

4 800169034 PLUG

5 800158289 ORING

6 800143054 PLUG

XCMG XE2000 excavator plug

800169034 End Cap

XCMG XE2000 Original Factory End Cap

800169034 Original factory sealing components

Excavator fluid system plug

XCMG XE2000 Pipeline Leakage Solution

Anti-corrosion and leak-proof excavator plugs

Brass plug

XE2000 Excavator Cavity Sealing Plug

800169034 Excavator parts

Mining operation sealing plug

Pipeline plugs during infrastructure construction

Engineering machinery fluid plug

XCMG XE2000 hydraulic system plug

Coolant chamber sealing plug