Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169023 o-ring XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator O-ring (part number 800169023): Seal and prevent leakage, protect the hydraulic system.

As a core sealing component of the hydraulic system of XCMG XE2000 excavator, the O-ring with part number 800169023 focuses on sealing and protecting the hydraulic interface. It can effectively prevent hydraulic oil leakage and the intrusion of contaminants such as dust and moisture. It is a key component to ensure the stable operation of the equipment’s hydraulic system in harsh working environments such as mines and infrastructure.

Original factory precise fit, seamless installation

Manufactured strictly according to the original design parameters of XCMG XE2000 excavators, the inner diameter, outer diameter, and cross-sectional dimensions are perfectly matched with the hydraulic interface, with a fit error of ≤0.03mm. There is no looseness or leakage after installation. A hydraulic maintenance case of an XE2000 fleet shows that after replacing the generic parts with this original O-ring, the interface leakage failure rate decreased by 80%, allowing for immediate operation without repeated adjustments and significantly shortening maintenance time.

Highly elastic and durable material, resistant to damage and corrosion.

Made from imported oil-resistant nitrile rubber, it combines high elasticity and anti-aging properties, allowing it to withstand the corrosion of hydraulic oil and diesel fuel for extended periods, and maintaining a stable sealing effect within a temperature range of -25℃ to 110℃. Actual test data shows that its tensile strength reaches 18MPa, and its service life is three times that of ordinary O-rings. Under an average of 10 hours of high-intensity operation per day, it can be used stably for more than 20 months, reducing frequent replacement costs.

High-efficiency sealing and protection, reducing costs and increasing efficiency

Through precision molding, the O-ring has a smooth, burr-free surface. When fitted to the interface, it forms a tight seal, preventing resource waste and environmental pollution caused by hydraulic oil leaks, while also blocking contaminants from entering the hydraulic system and preventing wear on core components such as pumps and valves. In a mining project in Inner Mongolia, XE2000 excavators equipped with these O-rings experienced a 65% reduction in hydraulic system failure frequency and annual maintenance cost savings exceeding 20,000 yuan.

Easy to install, cost-effective

Installation requires no special tools and can be completed using standard assembly procedures. The part numbers are clearly marked, facilitating quick identification and accurate matching by maintenance personnel, reducing the risk of incorrect installation. From a long-term cost perspective, its high durability and low failure rate can reduce the procurement and replacement costs of seals for the XE2000 fleet by 30%, making it particularly suitable for large fleet applications.

Select core advantages

Original factory quality: XCMG standardized production, meeting the stringent sealing requirements of equipment;

Precise fit: Dedicated XE2000 hydraulic interface, leak-proof and sealed;

Oil and corrosion resistant: Made of imported materials, suitable for harsh working conditions;

Highly protective: leak-proof and contamination-proof, safeguarding the hydraulic system;

Economical and practical: easy to install, long lifespan, and reduced overall operation and maintenance costs.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

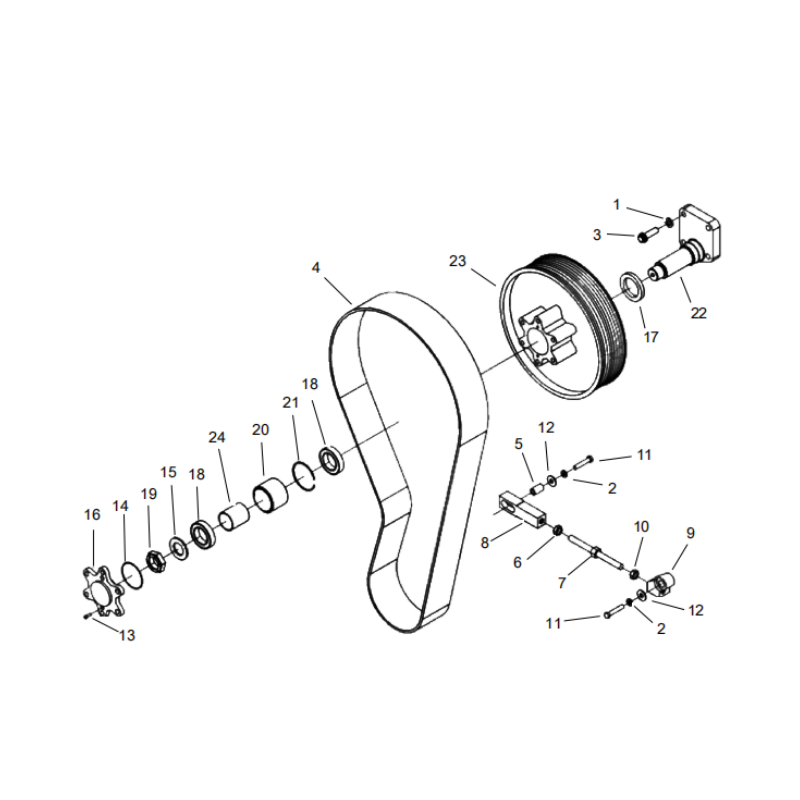

800169253 fan drive XCMG XE2000 excavator spare parts

1 805300217 LOCKNUT

2 800138361 LOCKINGPLATE

3 800168902 BOLT

4 860149534 HOOP

5 860149603 MOUNTINGGASKET

6 800169185 NUT

7 800169174 CONTROLLEVER

8 800169161 CONTROLRODEND

9 800169088 CONTROLRODEND

10 800169015 NUT

11 800169170 BOLT

12 860149604 MAT

13 800168917 BOLT

14 800169023 ORING

15 800169065 MAT

16 800169171 FANHUB

17 800169095 OILSEAL

18 800168882 ROLLERBEARING

19 800168981 CHECKNUT

20 800169176 BEARINGSPACER

21 800169019 LOCATINGRING

22 800169052 FANCENTERSHAFT

23 800169296 FANPULLEY

24 800169090 BEARINGSPACER