Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169020 aftercooler cover gasket XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator original hose clamp (part number 800158241): Secure clamping for leak-free hose connection.

In the hydraulic, fuel, and cooling systems of the XCMG XE2000 excavator, the sealing of hose and connector connections is fundamental to the machine’s stable operation. Loose connections and leaks can lead to decreased hydraulic pressure, fuel waste, and even engine overheating. Hose clamps, as the “key locking mechanism” for securing hoses, directly determine the safety of the connection. This article focuses on the XCMG XE2000 original hose clamp (part number 800158241), a high-pressure hose clamp specifically designed for this model. It provides strong clamping force to protect hose connections and eliminate the risk of leakage.

Precisely compatible with XE2000: Seamlessly matches original hose specifications

This hose clamp (part number 800158241) is custom-designed to precisely match the outer diameter, wall thickness, and connection space parameters of the hoses in various systems of the XCMG XE2000 excavator. Its clamping range accurately covers the corresponding hose sizes (such as hydraulic hoses and cooling water pipes), and the opening width perfectly matches the original factory design. No grinding, adjustment, or connector replacement is required; it can be directly fitted onto the connection between the hose and connector, providing a tight fit to the hose’s outer wall—avoiding displacement due to excessive looseness or damage to the hose wall due to excessive tightness. As a dedicated hose clamp for the XE2000, it forms a “three-in-one” compatible combination with original factory hoses and connectors, ensuring connection stability from the source.

High-strength material: corrosion-resistant and rust-resistant, suitable for harsh working conditions.

Made from high-quality stainless steel or hot-dip galvanized steel sheet through precision stamping, with an additional anti-corrosion coating, these hose clamps possess excellent corrosion and rust resistance. Even in humid and rainy environments with hydraulic oil/coolant splashes, they can resist rust for extended periods without structural deformation. Facing extreme temperature fluctuations from -40℃ to 120℃, the material’s mechanical strength remains stable, preventing a decrease in clamping force due to low-temperature brittleness or high-temperature softening. Compared to ordinary carbon steel hose clamps, their service life is extended by more than three times, enabling them to withstand the high-frequency vibrations and environmental corrosion of excavator operations for extended periods.

Strong anti-loosening clamping: Prevents leakage and ensures system stability

The hose clamp uses a worm gear drive or bolt fastening structure (as per original factory configuration). Once tightened, it generates a uniform and durable clamping force, firmly “locking” the hose to the connector and forming a tight seal. Even when the XCMG XE2000 experiences continuous vibration during heavy-duty operation, the hose clamp can resist the hose’s tendency to shift, preventing the formation of tiny gaps at the connection point due to vibration—a loosening-proof sealing effect that ordinary hose clamps cannot achieve. In practical applications, it effectively prevents hydraulic oil and coolant leakage, ensuring stable hydraulic system pressure and efficient cooling system heat dissipation, reducing downtime for maintenance due to leakage.

Each 800158241 hose clamp must pass three core tests conducted by XCMG:

Dimensional accuracy inspection: The clamping diameter, steel plate thickness, and bolt hole positions are calibrated using a laser measuring instrument, with the error controlled within ±0.02mm to ensure complete matching with the XE2000 hose;

Clamping force test: Using professional equipment to simulate long-term vibration and pressure, the clamping force attenuation rate is verified, and unqualified products are directly eliminated;

Corrosion resistance test: A 48-hour salt spray test is conducted to ensure that the coating does not peel off and the substrate does not rust, meeting the requirements of harsh outdoor working conditions.

Only products that pass all tests will be marked with part number 800158241 before leaving the factory, ensuring that every product received by the user is a reliable original part.

Key role: Safeguarding the core systems of excavators

Hydraulic system: Secure the connection between the hydraulic hoses and the cylinders/valve assemblies to prevent high-pressure oil leakage and ensure precise and powerful boom and bucket movements;

Cooling system: Tighten the connections between the coolant hoses and the radiator to prevent coolant loss and overheating of the engine and hydraulic oil;

Fuel system: Stabilizes the connection between the fuel line and the filter, prevents fuel leaks, reduces waste, and avoids safety hazards.

As a core hose fixing component for construction machinery, the XCMG XE2000 excavator hose clamp (part number 800158241) is an essential accessory for maintaining original factory quality and ensuring efficient excavator operation. Choosing the original factory hose clamp means choosing a leak-free connection, safety, and long-term stable operation.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169252 rear cooler XCMG XE2000 excavator spare parts

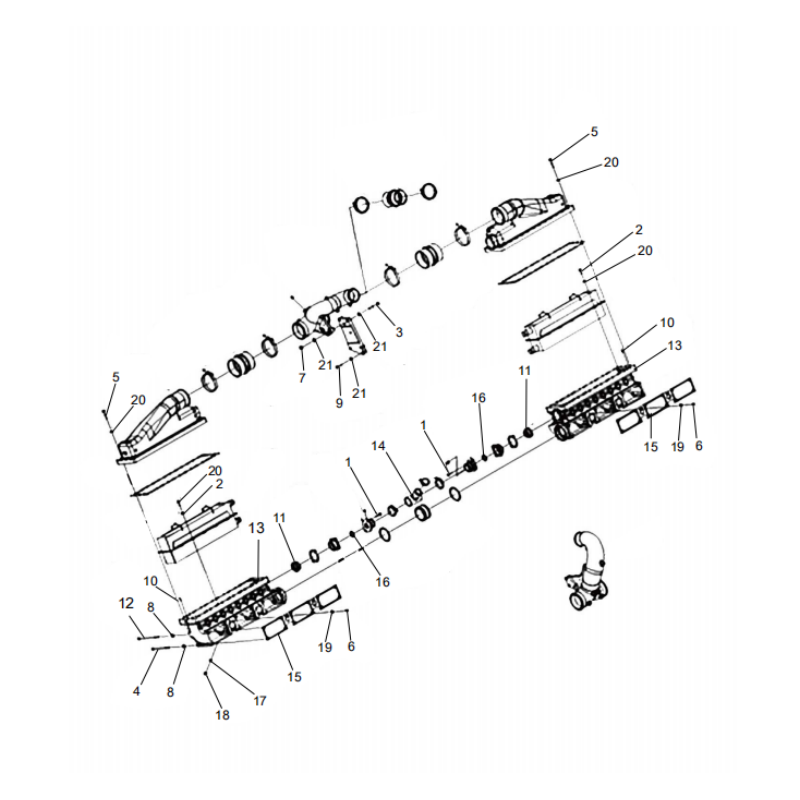

22 800167212 SEALRETAINER

23 800161836 O-RING6

24 800161657 COUPLINGGASKET

25 800167120 PIPEPLUG

26 800167007 PIPEPLUG

27 800158237 FLANGEHOSE

28 800169184 AIRCROSSCONNECTIONPIPE

29 800169133 AIRCROSSCONNECTIONPIPE

30 800169154 SUPPORTCONNECTION

31 800169060 DRAINVALVE

32 800169014 AFTERCOOLERCORE

33 800169105 AFTERCOOLERCOVER

34 800158238 TTYPECLAMP

35 800158239 FLANGEHOSE

36 800158240 HOSECLAMP

37 800158241 HOSECLAMP

38 800169139 AFTERCOOLERCOVER

39 800169020 AFTERCOOLERCOVER GASKET

40 800158242 TTYPECLAMP

41 800168973 CONNECTINGFLANGE

42 800169188 AIRBALANCEPIPE

XCMG XE2000 hose clamp

800158241 Genuine parts

Excavator high-pressure hose fixing clamp

XE2000 Dedicated Hose Clamp

Anti-loosening hose clamp

Construction machinery hose fixing components