Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800168958 bolt XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Bolt 800168958 | Original factory fit, high-strength fastening, vibration and corrosion resistant, ensuring stable connection of core components

In high-intensity operations such as hard rock excavation in mining and heavy-duty construction, the XCMG XE2000 excavator relies on bolts for reliable fastening in key areas such as the connection between the boom and the frame, the fixing of hydraulic valve groups, and the assembly of engine compartment components. The original XCMG XE2000 bolts (part number 800168958), as core fastening components, can withstand high-frequency vibration, impact loads, and corrosion under complex working conditions. They prevent component displacement and functional failure caused by bolt loosening, breakage, or corrosion, thus providing a solid “connection foundation” for the overall structural safety and efficient operation of the XE2000 excavator.

800168958 Bolt: Three core advantages, compatible with XE2000

Original factory precision fit: Dimensions strictly adhere to the XCMG XE2000 key component connection design standards. Thread specifications (standard thread type, pitch accuracy up to 6g level), rod length tolerance (±0.1mm), head-to-side distance, and mounting hole and matching nut are perfectly matched, allowing for direct tightening without secondary processing. The contact surface between the bolt head and washer is precision milled (flatness error ≤0.03mm) to avoid poor fit and stress concentration caused by adaptation deviations. It is compatible with various fastening requirements such as booms, hydraulic pumps, and cab frames, ensuring gapless component connections.

High strength, load and vibration resistance: Made of high-strength alloy structural steel (35CrMoA), and heat-treated as a whole (hardness HB240-280), with a tensile strength ≥980MPa and a yield strength ≥800MPa. It can withstand 1.5 times the rated impact load generated by the lifting and rotating of the excavator boom, preventing rod breakage and thread stripping. The thread surface is phosphated and coated with anti-loosening adhesive. After tightening, the self-locking coefficient is ≥0.4, which can withstand high-frequency vibration of 1800 times/minute without loosening. It effectively prevents abnormal noise and transmission jamming caused by loose bolts, ensuring long-term stable connection of core components.

Corrosion resistant, durable, and long service life: The surface is coated with a zinc-nickel alloy (coating thickness ≥10μm), with a salt spray resistance test of over 500 hours, which can resist the corrosion of mine dust, construction site rainwater, and hydraulic oil leakage, avoiding disassembly difficulties and thread damage caused by bolt corrosion; it maintains structural stability in a temperature range of -40℃ to 180℃, with no risk of low-temperature brittleness or high-temperature softening, making it suitable for high-temperature environments in engine compartments and low-temperature operating scenarios in northern winters; its service life exceeds 12,000 hours (90% longer than ordinary galvanized bolts), reducing frequent maintenance and downtime costs caused by bolt failure.

Suitable for multiple scenarios, with traceable quality, and safe to use.

Whether the XE2000 is operating in hard rock mining (high vibration, high dust conditions), heavy-duty earthmoving operations in infrastructure (continuous high loads), or in humid, rainy, and fluctuating outdoor environments, the 800168958 bolts consistently provide stable fastening. Each bolt undergoes XCMG’s triple testing (tensile strength test, thread accuracy calibration, and salt spray resistance test), conforming to the ISO 898-1 high-strength bolt standard and engineering machinery fastening component specifications. Official traceability is supported (scanning the anti-counterfeiting code on the bolt head verifies authenticity), ensuring safe and trouble-free use and preventing equipment damage and operational accidents caused by the breakage of inferior bolts.

Select 800168958 to protect the structural safety of XE2000.

If you are facing issues such as loose or corroded bolts on key components of your XCMG XE2000 machine, or if you need to replace aged or broken bolts, the original 800168958 bolt is the best choice. Its reliable high strength and vibration resistance ensure that core component connections do not fail, reducing the risk of structural failures and helping the XE2000 maintain stable operation under various high-intensity working conditions, thus promoting the efficient execution of engineering tasks.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169244 front-gear drive-system auxiliary drive XCMG XE2000 excavator spare parts

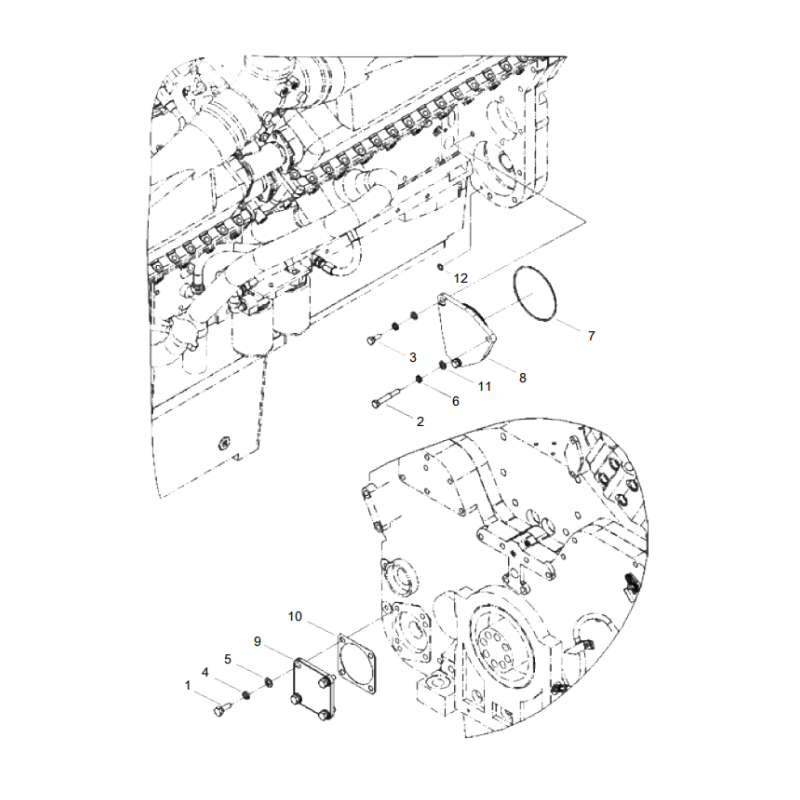

1 800168958 BOLT

2 800169101 BOLT

3 800167065 HEXAGONSCREW

4 800169113 WASHER

5 800169075 WASHER

6 800169180 WASHER

7 800158325 ORING

8 860149587 HYDRAULICPUMPBLINDFLANGE

9 800168946 BLINDFLANGE

10 800167063 GASKETFORHANDHOLE

11 800168926 WASHER

12 800142725 ORING

XCMG XE2000 excavator bolts

800168958 Bolt

XCMG XE2000 Original Bolts

800168958 Original factory fasteners

High-strength bolts for excavators

XCMG XE2000 Component Loosening Solution

Vibration-resistant and anti-loosening excavator bolts

35CrMoA alloy bolts

XE2000 Excavator Boom Connection Bolts

800168958 Excavator Parts

Mining operation fastening bolts

Construction heavy-duty excavator bolts

Anti-corrosion bolts for construction machinery

XCMG XE2000 hydraulic pump fixing bolts

High and low temperature resistant excavator bolts