Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800168946 blind flange XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Blind Flange 800168946 | Original factory seal, pressure resistant and corrosion resistant

In mining and infrastructure operations, improper sealing of pre-existing pipeline ports can easily lead to leaks and dust ingress, causing pressure drops and component wear. XCMG’s original blind flange 800168946 precisely matches pipeline interfaces, providing robust protection for pipeline systems with “zero leakage sealing, pressure resistance without deformation, and corrosion resistance with a long service life.”

Three core advantages to solve the pain points of blocking

1. Original factory precise fit, no dead corners in sealing

The dimensions fully comply with the XE2000 design, with an outer diameter tolerance of ±0.08mm and a bolt hole position error of ≤0.05mm. Direct assembly is possible without machining.

With a sealing surface flatness of ≤0.02mm, and when paired with original gaskets (recommended 800169076), it achieves zero leakage under 35MPa high pressure, eliminating the oil leakage problem of ordinary flanges.

2. High-strength resistance to extreme working conditions

The base material is Q345B steel, integrally forged and quenched and tempered, with a tensile strength ≥510MPa and a deformation resistance exceeding that of ordinary carbon steel by 40%.

The edges are rounded with R3 to relieve stress, and the material does not deform or crack in environments ranging from -40℃ to 150℃, making it suitable for mining impacts and high and low temperatures.

3. Double corrosion resistance, lifespan over 1.8 times longer.

Sandblasting (Sa2.5 grade) + epoxy resin coating (≥60μm), no rust after 600 hours of salt spray test (ordinary flanges only 330 hours);

With a lifespan exceeding 15,000 hours in dusty and muddy mining environments, it reduces replacement frequency by more than 3 times, lowering maintenance costs.

Stable performance in multiple scenarios, with traceable quality.

Mining/Infrastructure: Corrosion and impact resistant, ensuring the safety of hydraulic and fuel pipeline sealing;

Inspection and maintenance: Easy to disassemble and assemble, reducing maintenance time by 50%;

Original factory triple testing (pressure resistance 40MPa, sealing for 72 hours, corrosion resistance for 600 hours), supports QR code traceability, eliminating the risk of counterfeit products.

Why choose 800168946?

Compared to aftermarket products: no leakage, lifespan increased by 80%;

Compared to ordinary carbon steel: corrosion resistance is increased by 70%;

Compared to general-purpose flanges: no modification required, saving labor time.

For XE2000 pipeline leaks and flange corrosion, choose the original factory blind flange 800168946 to protect pipeline safety and reduce operating costs.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

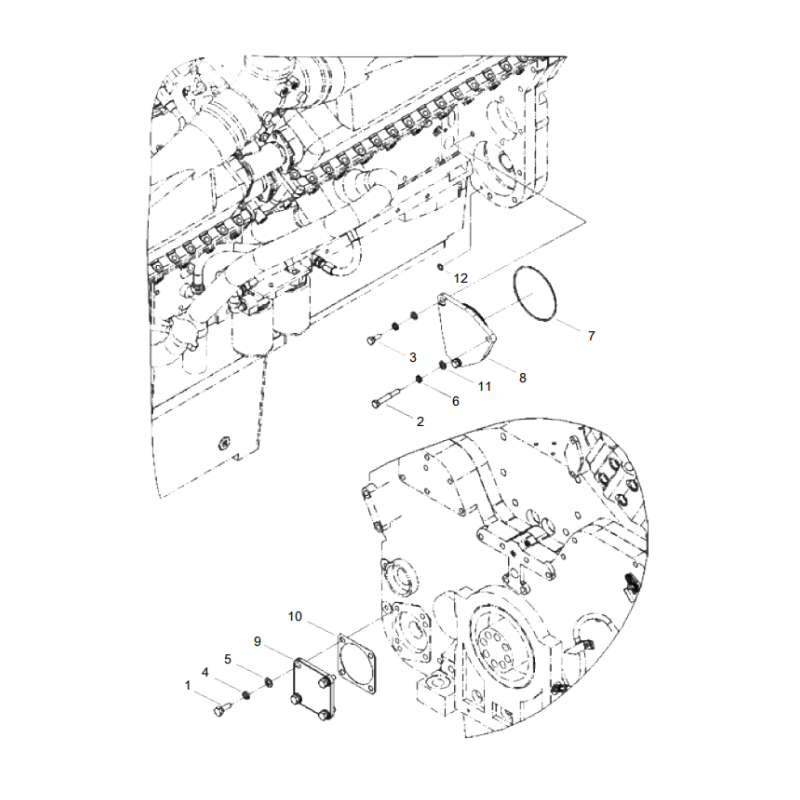

800169244 front-gear drive-system auxiliary drive XCMG XE2000 excavator spare parts

1 800168958 BOLT

2 800169101 BOLT

3 800167065 HEXAGONSCREW

4 800169113 WASHER

5 800169075 WASHER

6 800169180 WASHER

7 800158325 ORING

8 860149587 HYDRAULICPUMPBLINDFLANGE

9 800168946 BLINDFLANGE

10 800167063 GASKETFORHANDHOLE

11 800168926 WASHER

12 800142725 ORING

XCMG XE2000 excavator blind flange 800168946

800168946 Original blind flange

XCMG XE2000 Pipeline Sealing Fittings

Excavator hydraulic pipeline blind flange

Corrosion Resistance of Blind Flanges in Mining Operations

800168946 Sealing Flange

High-strength excavator blind flange 35MPa

800168946 Excavator Parts

Infrastructure construction blind flange leak prevention

Salt spray resistant excavator blind flange 600 hours