Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800168925 the flywheel shell XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Dedicated Flywheel Housing: Part No. 800168925

As the “core carrier” of the XCMG XE2000 excavator’s power transmission system, the flywheel housing not only secures the flywheel and connects the engine and gearbox, but also withstands high-frequency vibrations and torque impacts during power transmission. Its structural stability and fitting precision directly determine the equipment’s power output efficiency. Our 800168925 flywheel housing is a custom-designed original equipment manufacturer (OEM) part specifically for the XE2000 model. Manufactured strictly according to XCMG’s original technical drawings and casting standards, every aspect, from the housing’s dimensions and bearing hole positions to the mounting flange surface, has undergone precision milling on a five-axis machining center—with overall dimensional errors controlled within ±0.05mm, bearing hole coaxiality reaching 0.03mm, and flange surface flatness ≤0.02mm/100mm. It can perfectly align with the XE2000 engine block and gearbox input end, requiring no additional modifications for direct assembly. This completely eliminates potential problems such as power transmission jamming and bearing wear caused by housing misalignment, laying the foundation for stable operation of the power system.

The dual upgrades in materials and manufacturing processes give this flywheel housing superior impact resistance and durability. It is integrally cast from QT450-10 ductile iron, undergoing high-temperature aging treatment to eliminate internal stress, achieving a tensile strength exceeding 450MPa and a yield strength exceeding 310MPa. This allows it to easily withstand the torque impacts and vibration loads generated during high-load engine operation. The housing surface is treated with an 80μm thick electrophoretic anti-rust coating, effectively resisting mud and water immersion and dust corrosion in mining and construction environments, preventing rust and cracking. Compared to ordinary gray cast iron flywheel housings, its fatigue resistance is improved by more than 5 times, maintaining structural stability even under long-term heavy-load conditions. This significantly reduces the need for major power system overhauls due to housing damage, lowering equipment maintenance costs.

Whether you’re the maintenance manager of an engineering team needing to replace a damaged flywheel housing during powertrain system maintenance, or a parts distributor looking to stock highly compatible and reliable core transmission system spare parts for your customers, the 800168925 flywheel housing is the preferred solution. We have a standardized, intelligent warehousing center with ample regular inventory, ensuring timely parts supply and uninterrupted maintenance schedules. Contact us now for tiered pricing on bulk purchases, making procurement costs more controllable and ensuring a more worry-free partnership!

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

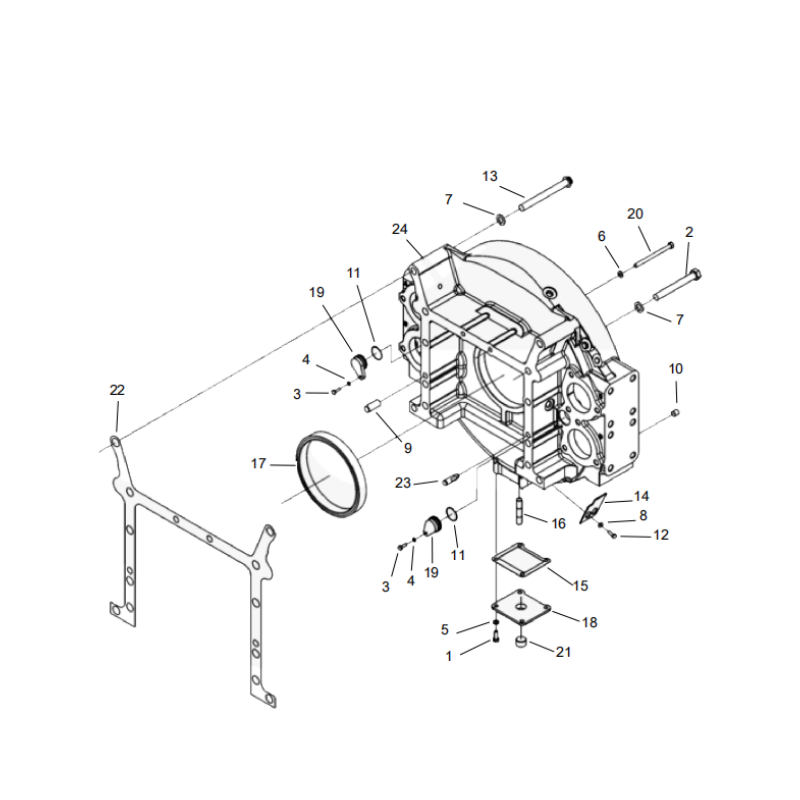

800169234 the flywheel shell XCMG XE2000 excavator spare parts

1 860135156 BOLT

2 800168895 BOLT

3 800169073 BOLT

4 800167675 CHECKNUT

5 800138362 MAT

6 800138361 LOCKINGPLATE

7 860530224 LOCKWASHER

8 800167678 CHECKNUT

9 800167011 SETPIN

10 800168942 SOCKETHEADSCREW

11 800169025 O-RING

12 800169028 BOLT

13 800169163 BOLT

14 800169092 OILBAFFLE

15 819902884 OILDRAINGASKET

16 800169038 DOUBLE-ENDFLATSTUD

17 800169102 OILSEAL

18 819902892 FLYWHEELBOTTOMCOVER

19 800168891 ACCESSHOLECOVER

20 800169001 BOLT

21 800162089 PLUG

22 800158298 FLYWHEELHOUSINGGASKET

23 800167077 DIAMOND-SHAPEDPIN

24 800168925 THEFLYWHEELSHELL

XCMG XE2000 flywheel housing, 800168925 parts, XE2000 excavator spare parts, XCMG 800168925 flywheel housing, XE2000 special flywheel housing, impact-resistant excavator flywheel housing