Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800168884 turbocharger plumbing XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator turbocharger pipe (part number 800168884): High temperature and high pressure resistant, empowering the engine with strong power.

The turbocharger in the XCMG XE2000 excavator is a core component for enhancing engine power and optimizing fuel efficiency. The turbocharger piping, acting as the “transmission channel” between high-temperature exhaust gas and compressed air, directly determines the turbocharger’s performance through its sealing and temperature resistance. Leaks or deformation in the piping can lead to power loss, increased fuel consumption, and even damage to the turbocharger and engine. This article focuses on the original XCMG XE2000 turbocharger piping (part number 800168884), a high-temperature turbocharger piping for excavators that uses precision manufacturing and reliable performance to ensure stable operation of the turbocharger system.

Precisely compatible with XE2000: Seamless integration with original factory systems

This pipe (part number 800168884) is custom-made strictly according to the interface specifications, engine compartment layout, and piping routing of the XCMG XE2000 excavator turbocharger. The pipe length, diameter variations, and flange dimensions are completely consistent with the original factory specifications. Whether it is the “high-temperature exhaust gas end” connecting the turbocharger and the exhaust manifold, or the “compressed air end” connecting the turbocharger and the intercooler, no cutting, welding, or modification of the joints is required. It can be directly and precisely connected, and the flange sealing surface fits tightly, eliminating airflow leakage caused by dimensional deviations. Ensuring the coordinated operation of the turbocharger and engine from the source is the core advantage of the XE2000 dedicated turbocharger pipe.

Special material: Resistant to high temperature of 1000℃ and high pressure impact.

Made of high-temperature resistant stainless steel (304/316L, according to original factory specifications) using precision bending and welding processes, it possesses excellent high-temperature and high-pressure resistance: It remains undeformed and unoxidized even when exposed to exhaust gases exceeding 1000℃ from turbochargers; under 1.5MPa compressed air pressure, the pipe wall shows no bulging or leakage, and it can withstand high-frequency pressure fluctuations. The high-temperature resistant coating reduces heat loss at the exhaust end and prevents external heat intrusion at the compression end, ensuring efficient energy utilization of the exhaust gas while preventing compressed air temperature rise from affecting the intercooling effect. Its service life is more than three times longer than ordinary carbon steel pipes.

Low-drag, smooth design: improving turbocharger efficiency

The pipe body features a streamlined structure with finely polished inner walls (roughness Ra≤1.6μm), eliminating weld seam protrusions or abrupt diameter changes to minimize airflow resistance. During heavy-duty operation of the XE2000, high-temperature exhaust gas can quickly drive the turbine to rotate, ensuring smooth delivery of compressed air to the intercooler and reducing energy loss. Compared to non-original piping, the turbocharger’s response speed is improved by 10%, resulting in stronger and smoother engine power output, fully adapting to the high-load operation requirements of excavators. It is a typical low-resistance turbocharger piping system.

Key role: Safeguarding power and safety

Exhaust gas transport: efficiently transports high-temperature exhaust gas to drive the turbine rotation and ensure the turbocharger starts normally;

Air delivery: Smoothly delivers compressed air to the intercooler, providing high-density intake air to the engine and improving combustion efficiency;

Safety protection: Prevents high-temperature exhaust gas from leaking out, avoids scalding surrounding parts, prevents impurities from entering the turbocharger, and reduces internal wear.

As a core component of turbochargers for construction machinery, the turbocharger piping (part number 800168884) for XCMG XE2000 excavators is an essential part for maintaining original power performance and extending the life of the engine and turbocharger. Choosing original piping means choosing stable power and long-term operational safety.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169245 turbo charger plum bing XCMG XE2000 excavator spare parts

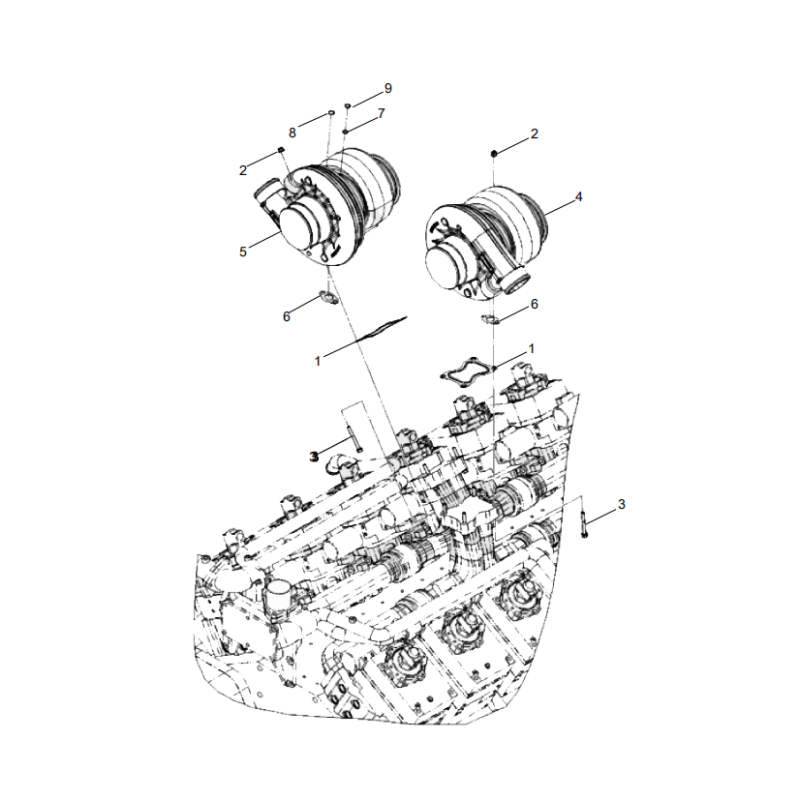

1 800167647 SUPERCHARGERGASKET

2 800168962 CHECKNUT

3 800169147 BOLT

4 800168884 TURBOCHARGERPLUMBING

5 800169199 TURBOCHARGERPLUMBING

6 800169058 CONNECTINGGASKET

7 860149567 ORING

8 800143977 ORING

9 800158307 ORING

XCMG XE2000 turbocharger piping

800168884 Genuine parts

Excavator high temperature booster pipe

XE2000 Dedicated Pressure Boosting Pipeline

Low-resistance booster pipeline

Core components of turbochargers for construction machinery