Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800167225 water delivering pipe XCMG XE2000 excavator spare parts

Share:

Product Details:

【XCMG XE2000 Dedicated Water Pipe | Original Part Number 800167225 | High-Efficiency Flow Diversion, Pressure Resistant, and Leak-Proof】

As the XCMG XE2000 excavator continuously faces the harsh challenges of heavy-duty and extreme high-temperature environments in mining, the reliability of the cooling system directly determines the overall operational stability and lifespan of the machine. As the core channel for coolant circulation, the water pipes’ pressure resistance, aging resistance, and sealing performance directly affect the heat dissipation efficiency of the engine and hydraulic system. Original equipment manufacturer (OEM) quality is the fundamental guarantee for the efficient operation of the equipment’s thermal management system.

Introducing the XCMG XE2000 original water supply pipe (part number: 800167225) – specially designed for the high temperature and high pressure conditions of ultra-large excavators, it provides smooth flow and leak-proof sealing to ensure efficient coolant delivery and prevent system failures caused by pipeline problems.

Core advantages

1. Original factory precision matching

Manufactured strictly according to the XCMG XE2000 cooling system piping standards, the pipe diameter, bending radius, interface size and material hardness are fully compatible with the original vehicle, and can be installed directly without adjustment, eliminating insufficient flow, leakage or localized high temperature caused by size deviation.

2. High voltage resistance and pulse protection for long-term reliability

It adopts a high-strength rubber composite layer and Kevlar reinforcing fiber, which increases the pressure resistance by 50%, resists pulse impact and high-frequency vibration, and maintains structural stability for a long time in high-temperature coolant circulation, with no risk of cracking or deformation.

3. Sealed, leak-proof, corrosion-resistant, and aging-resistant

The original multi-layer sealing interface and chemical corrosion resistant materials effectively prevent coolant leakage and scale buildup, adapt to high temperature, high humidity and multi-additive working environments, and extend service life.

4. Ensure efficient heat dissipation and reduce system risks

Original factory coolant hoses ensure lossless coolant delivery, preventing engine overheating and hydraulic system performance degradation caused by leaks or blockages, and reducing unplanned downtime and maintenance costs.

Applicable Information

• Applicable Models: XCMG XE2000 Series Extra-Large Excavators

• Installation location: Coolant delivery lines between the engine, hydraulic oil cooler, and water pump.

• Typical operating conditions: mining, continuous heavy-load operation, high-temperature and high-pressure cooling environment.

Choose genuine water hoses to build an efficient and reliable cooling lifeline for your XE2000!

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169247 water manifold XCMG XE2000 excavator spare parts

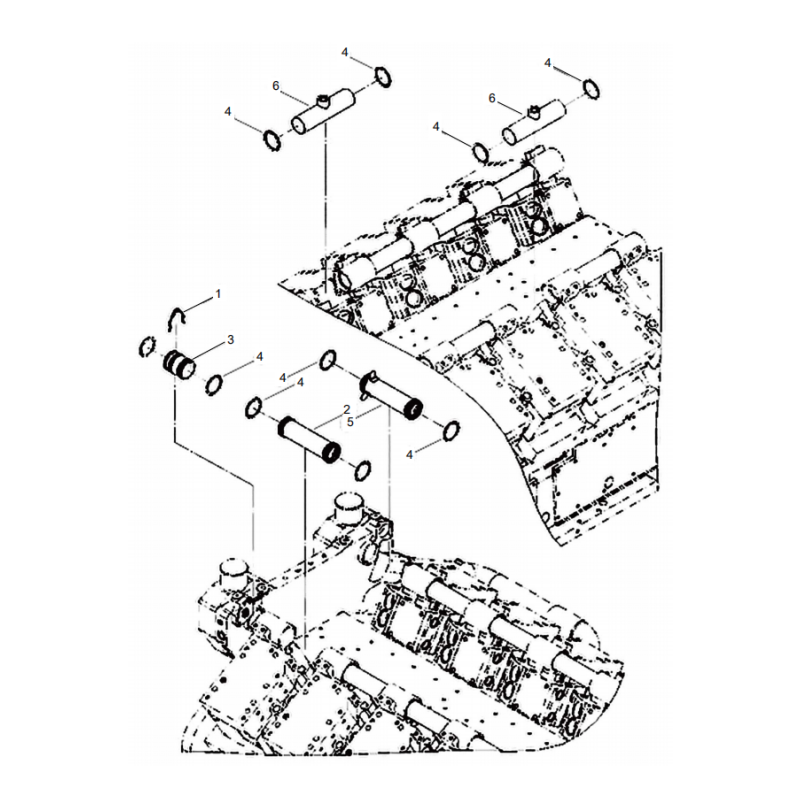

1 860149593 LOCATINGRING

2 800167222 Water Delivery Pipe

3 800167223 Water Delivery Pipe

4 800161829 O-RING3

5 800167224 Water Delivery Pipe

6 800167225 Water Delivery Pipe