Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800167176 camshaft gear XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Camshaft Gear (Part No. 800167176): A Key Transmission Component for Precise Valve Timing

The XCMG XE2000 mining excavator, with its 192,000kg operating weight, 810kW imported engine, and 10-14m³ bucket capacity, consistently delivers powerful performance in heavy-duty mining operations worldwide. The camshaft gear (part no. 800167176), as a core transmission component of the engine’s valve train, is crucial for ensuring precise valve timing, directly impacting fuel combustion efficiency and power output stability.

This camshaft gear is precision forged from high-strength alloy structural steel, possessing excellent mechanical strength and wear resistance. To meet the demands of high-frequency, full-load engine operation in mining, the gear teeth undergo advanced carburizing and quenching processes, achieving a carburized layer depth of 1.0-1.3mm and a surface hardness of 58-62HRC. The tooth root fillets are strengthened through rolling, effectively resisting contact fatigue and bending stress caused by long-term meshing, preventing fatal failures such as tooth surface spalling and tooth breakage, and ensuring the long-term stable operation of the valve train.

In terms of design, supported by data from XCMG’s engine dynamics laboratory, the gear module, tooth ratio, and tooth profile curve underwent 1500 hours of bench testing. High-precision involute tooth profiles and edge-modified designs are employed, with the meshing clearance with the crankshaft gear strictly controlled within the optimal range of 0.03-0.05mm. The transmission ratio accuracy error is less than 0.01%, and the camshaft rotation angle is precisely controlled to ensure that the valves open and close at the optimal times during intake, compression, power, and exhaust strokes, achieving complete fuel combustion.

Leveraging XCMG’s intelligent manufacturing system, the entire gear manufacturing process utilizes a digital traceability system. The CNC gear hobbing machine achieves IT5 precision, with a cumulative pitch error of ≤0.02mm and a tooth direction error of ≤0.015mm, ensuring smooth transmission. The gear inner hole and locating keyway are machined using an integrated process, with a coaxiality error of less than 0.01mm, preventing eccentricity and wobbling after assembly. Each gear undergoes 100% magnetic particle testing and tooth surface hardness testing to eliminate internal cracks and machining defects.

In actual mining operations, the precise transmission of the camshaft gear directly brings multiple core benefits: First, by stably controlling valve timing, it allows for more complete fuel combustion under heavy-load climbing and full-bucket digging conditions, reducing fuel consumption by 6-9%; second, it reduces the impact load on the valve train, lowering the wear rate of components such as valves, rocker arms, and tappets, extending the overhaul cycle of the valve train by more than 40%; third, it reduces engine operating noise by 2-4 decibels, improving driving comfort while reducing mechanical fatigue damage. Facing the complex environment of mines, this gear exhibits excellent environmental adaptability. The tooth surface undergoes special phosphate treatment to enhance wear resistance and rust prevention, maintaining stable performance over long periods in dusty and high-humidity environments. The inner bore mating surfaces are precision ground and polished, with a roughness controlled within 0.8μm, ensuring a tight fit with the camshaft and reducing vibration and energy loss during operation. Choosing the XCMG XE2000 excavator camshaft gear (part number 800167176) not only provides you with a high-precision transmission component compatible with the original engine, but also allows you to benefit from XCMG’s global parts service network, including 24-hour technical consultation, fast logistics delivery, and professional installation guidance. Let this precisely controlled transmission component solidify the power output foundation of your mining equipment and continuously create production value.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

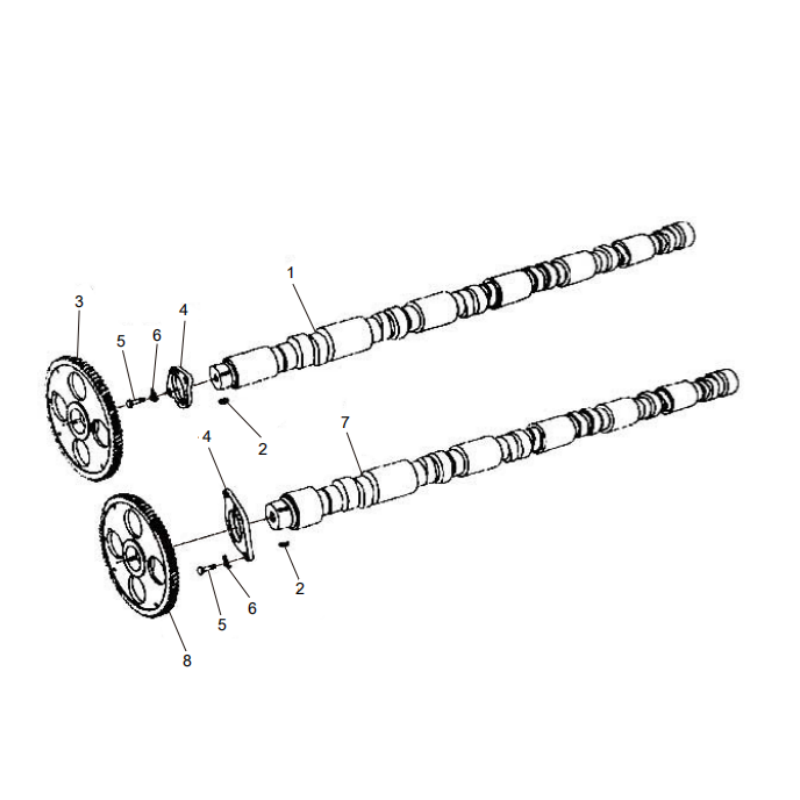

800169281 camshaft and gear XCMG XE2000 excavator spare parts

1 800169049 1 CAMSHAFT

2 800167175 2 SEMI-CIRCLE KEY

3 800167176 1 CAMSHAFT GEAR

4 800167177 2 CAMSHAFT THRUST BEARING

5 800142946 4 BOLT

6 800167179 4 LOCKING PLATE

7 800169197 1 CAMSHAFT

8 800169009 1 CAMSHAFT GEAR