Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800166989 crankshaft gear XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Crankshaft Gear (Part No. 800166989): A Precision Gear for Power Transmission

In heavy-duty mining operations worldwide, the XCMG XE2000 mining excavator, with its robust configuration of a 192,000kg operating weight, an 810kW imported engine, and a large bucket capacity of 10-14m³, operates continuously and efficiently. The crankshaft gear (part no. 800166989), as a key component of the engine’s power transmission, is a crucial link connecting the crankshaft to other auxiliary systems, directly affecting the accuracy and stability of the machine’s power transmission.

This crankshaft gear is precision-machined from high-strength alloy structural steel, possessing excellent wear resistance and structural strength. Facing the continuous meshing requirements of the XE2000 engine’s high-speed operation, the gear tooth surface undergoes special hardening treatment, enabling it to withstand long-term, high-frequency power transmission friction, effectively resisting tooth surface wear and pitting, preventing power interruption due to gear failure, and providing a reliable power source for the normal operation of the engine’s auxiliary systems. In terms of design, it is based on specialized research and development of engine transmission system parameters. The gear module, number of teeth, and tooth profile accuracy have been precisely calculated and optimized. Through high-precision tooth profile machining and meshing clearance control, it ensures perfect meshing with the crankshaft and other transmission gears, achieving efficient power transmission and reducing energy loss and noise during transmission. Precise phase positioning design ensures the synchronization of the engine’s valve train, fuel injection system, and crankshaft operation, improving engine efficiency.

Relying on XCMG’s advanced manufacturing processes, this crankshaft gear undergoes rigorous precision testing and performance evaluation. It is machined using high-precision hobbing and shaving processes, with tooth pitch error controlled at the micron level to ensure smooth transmission. The surface is carburized and quenched, achieving a tooth surface hardness of HRC or higher, while the core maintains good toughness, combining high wear resistance and impact resistance. Each gear undergoes rigorous dynamic balancing testing and dimensional verification to eliminate machining defects and ensure reliable operation after installation.

The performance of the crankshaft gear directly affects the collaborative efficiency of the engine’s auxiliary systems. Through precise power transmission, it drives the valve train to open and close the valves at optimal times, ensuring complete fuel combustion and improving engine power output and fuel economy. Simultaneously, it provides stable power to key auxiliary components such as the fuel pump and water pump, ensuring the normal operation of engine cooling and lubrication systems. Stable transmission performance also reduces impact on related components, extending the overall engine lifespan.

Choosing the XCMG XE2000 excavator crankshaft gear (part number 800166989) not only provides you with high-quality gear components that are precise, durable, and reliable, but also allows you to enjoy timely parts supply and professional technical support through XCMG’s global service network. Let this precise power transmission gear safeguard the engine system of your mining equipment and contribute to efficient and stable production.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

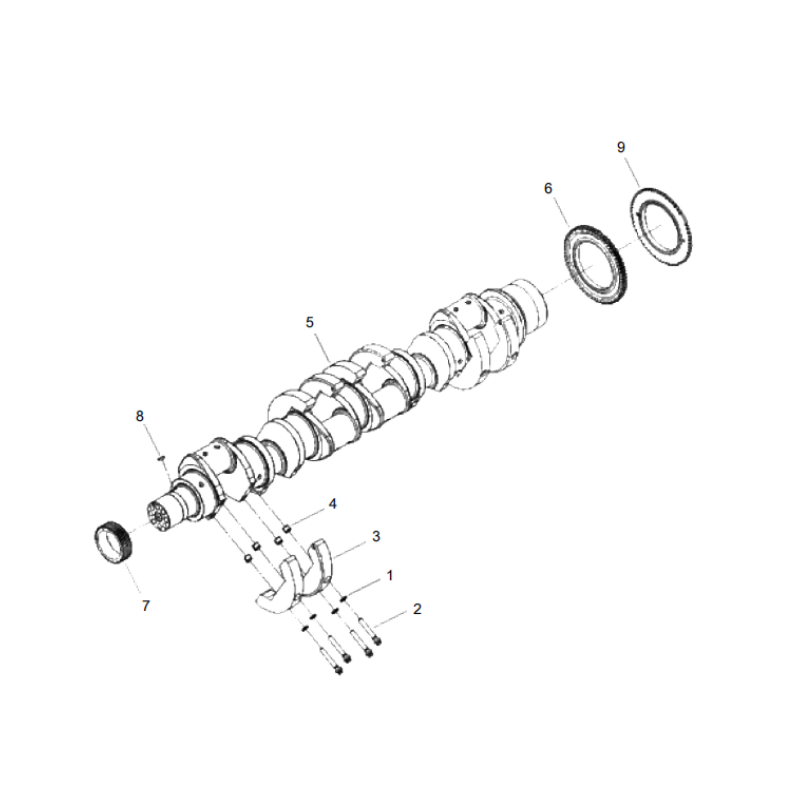

800169285 CRANKSHAFT

1 800166987 16MAT

2 800166986 16 SCREW

3 800166985 8 CRANKSHAFT COUNTER WEIGHT BLOCK

4 800169046 16 DOWEL RING

5 800169153 1 ENGINE CRANKSHAFT

6 800166988 1 CRANKSHAFT GEAR

7 800166989 1 CRANKSHAFT GEAR

8 800166983 2 SEMI-CIRCLE KEY

9 800166982 1 SPEEDOMETER RING