Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800158171 tube XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Pipe (Part No. 800158171): The Artery of Medium Transmission in Heavy-Duty Systems

In the global heavy-duty construction field of mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and large bucket capacity of 10-14m³, has become a “pillar of efficiency” in mining operations. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, it consistently conquers extreme working conditions with its stable and efficient performance. Within its complex fluid transmission system, the pipe (part no. 800158171), acting as the “artery of medium transmission,” is a core component ensuring the precise delivery of critical media such as hydraulic oil and coolant.

I. Core Responsibility for Multi-System Media Transmission

Stable High-Pressure Media Delivery: The XE2000’s hydraulic system operates at pressures up to 35MPa. During high-intensity excavation operations, the pipe (800158171) undertakes the critical media transmission task in the oil circuit, connecting the hydraulic pump, control valves, and actuators to ensure efficient conversion of hydraulic energy into mechanical power. Its smooth inner wall design reduces media flow resistance and pressure loss. In heavy-duty breaking operations after hard rock blasting, it can stably withstand pulse pressure impacts, avoiding power interruptions due to pipeline failure and ensuring construction continuity.

Multi-Media Adaptability: In addition to hydraulic oil, this pipe can also adapt to the transmission needs of various media such as coolant and lubricating oil. In extreme temperature environments ranging from -30℃ to 50℃, its excellent high and low temperature resistance ensures that the media does not condense at low temperatures and does not leak at high temperatures, providing a reliable channel for heat dissipation and lubrication of core components such as the engine and hydraulic system. In high-humidity, high-salinity environments such as coastal mining areas, it effectively resists media corrosion and external rust, ensuring unimpeded media transmission across multiple systems.

II. Superior Performance Designed for Heavy-Duty Operations

High-Strength Materials and Precision Manufacturing: To meet the heavy-duty requirements of the XE2000, the pipe (800158171) is made of high-strength seamless alloy steel, with a tensile strength exceeding 630MPa, far surpassing the standards for ordinary engineering machinery pipelines. The inner wall of the pipe undergoes precision polishing, with a roughness Ra≤0.8μm, reducing media flow resistance and turbulence loss; the joints are precision forged to ensure that the flatness error of the sealing surface is controlled within 0.02mm, completely eliminating the risk of leakage under high pressure. After multi-layer composite anti-corrosion treatment, the surface can withstand salt spray testing for over 1100 hours, maintaining stable performance for a long time in harsh mining environments. Optimized layout for overall machine adaptation: XCMG engineers, through 3D simulation and extensive on-site testing, tailored the pipe routing and bending angles for the XE2000. The piping cleverly avoids interference areas with moving parts such as the boom and slewing mechanism, and is secured with specialized pipe clamps, reducing vibration and wear and extending pipe lifespan by over 55%. This high degree of adaptability to the overall machine structure ensures stable pipe transmission during full-range operation, preventing malfunctions caused by bending and friction.

III. Quality and Service Assurance Under Rigorous Testing

Comprehensive Performance Limit Testing: Every batch of pipes (800158171) undergoes multiple rigorous tests before leaving the factory: a water pressure burst test at 2.2 times the working pressure (50 minutes without leakage), a high and low temperature cyclic impact test from -40℃ to 120℃ (700 cycles without cracks), a vibration fatigue test of 1.3 million cycles (simulating 7 years of working conditions), and a media corrosion resistance test (immersion in hydraulic oil and coolant for 300 hours without abnormalities). This series of strict tests ensures the long-term reliability of the product under extreme working conditions.

In the mining construction industry, where “smooth flow equals efficiency,” the XCMG XE2000 excavator pipe (part number 800158171) provides superior transmission performance, ensuring the efficient operation of multiple equipment systems. Choosing this original equipment manufacturer (OEM) pipe not only reduces the risk of downtime due to pipeline failures but also improves the overall operating efficiency of the equipment, continuously creating value for mining production. Let XCMG’s original factory quality be your reliable guarantee for heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

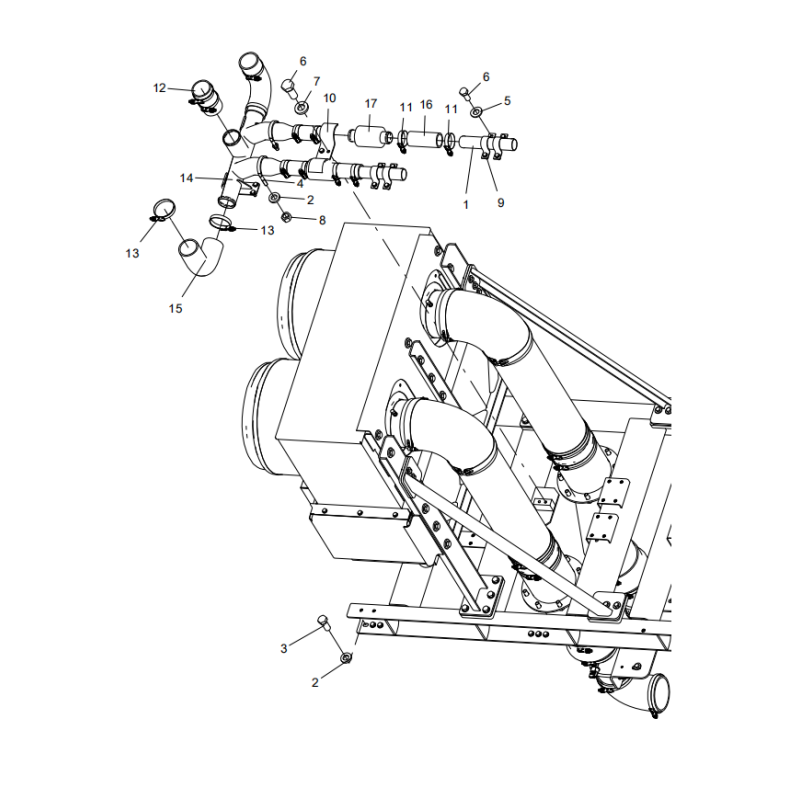

318302434 engine air intake system XCMG XE2000 excavator spare parts

1 318303104 2 STEEL PIPE

2 329900303 32 THICKENED FLAT WASHER

3 805006412 30 BOLT M12×30 GB/T5783-2000

4 329900601 2 U-SHAPED PIPE CLAMP

5 805338279 12 WASHER 10 GB/T97.1-2002

6 805011330 14 BOLT M10×25 GB/T5783-2000

7 329900302 12 THICKENED FLAT WASHER

8 805238372 12 NUT M12 GB/T6170-2000

9 318805404 4 HOOP

10 318303249 1 PRESSURE PLATE

11 800163868 8 HOOP

12 800158171 1 TUBE

13 800163863 6 HOOP

14 318303105 1 STEEL PIPE ASSEMBLY

15 800171548 2 TUBE

16 800166844 4 TUBE

17 800160501 2 CHECK VALVE