Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800152621 fuel radiator XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Fuel Radiator (Part No. 800152621): High-Efficiency Heat Dissipation Ensures Stable Fuel System Operation

In the fuel supply system of the XCMG XE2000 excavator, the fuel radiator is a key heat dissipation component for maintaining stable fuel temperature and ensuring combustion efficiency. The fuel radiator, part number 800152621, is specifically designed for the fuel cooling needs of the XE2000 excavator, providing a solid guarantee for the efficient operation of the fuel system during high-intensity operation with its superior heat dissipation performance and structural reliability.

This fuel radiator is precision-machined from high-quality aluminum alloy. The core heat dissipation core adopts a multi-channel flat tube and corrugated fin combination structure, increasing the heat dissipation area by more than 30% compared to traditional structures. To address the continuous rise in fuel temperature during heavy-load operation of the XE2000 excavator, the 800152621 fuel radiator quickly dissipates excess heat from the fuel, stabilizing the fuel temperature within the optimal operating range. This prevents problems such as poor atomization and incomplete combustion caused by overheating, ensuring stable engine power output and reducing fuel consumption and emissions.

In terms of heat dissipation efficiency, the internal flow channel design of the 800152621 fuel radiator has been optimized through fluid dynamics simulation. The fuel flows along a reasonable path within the radiator, with uniform flow velocity and no dead zones, allowing for full contact and heat exchange with the cooling fins. Simultaneously, the fin spacing has been precisely calculated, ensuring smooth airflow while maximizing the heat dissipation area, significantly improving heat dissipation efficiency. Even in high-temperature environments or during prolonged full-load operation, it can quickly reduce fuel temperature, ensuring the fuel system remains in optimal operating condition.

Regarding structural reliability, the core components of this fuel radiator are made of high-strength aluminum alloy, undergoing corrosion-resistant treatment and pressure testing, exhibiting excellent impact resistance and sealing performance. The connection between the radiator core and the oil inlet/outlet ports is achieved through precision welding, resulting in smooth, tight welds with no leakage risks. This allows for long-term resistance to fuel corrosion and system pressure shocks. The outer shell is manufactured using a stamping process, ensuring a robust structure that effectively protects the internal radiator core from external impacts and dust erosion, extending the radiator’s lifespan.

Regarding compatibility, the fuel radiator with part number 800152621 is an original accessory for the XCMG XE2000 excavator, perfectly matching the equipment’s fuel lines and mounting bracket interface specifications. The radiator’s dimensions, inlet/outlet port positions, and other parameters strictly adhere to the original factory design standards. No modifications to the equipment structure are required during installation. It precisely connects to the fuel system lines and mounting brackets, ensuring a stable installation and reducing the risk of decreased cooling efficiency or leakage due to poor compatibility. Whether assembling a new machine or replacing an old part, installation can be completed quickly, significantly reducing equipment downtime for maintenance.

The 800152621 fuel radiator demonstrates excellent durability and environmental adaptability. The radiator core undergoes anodizing, forming a dense oxide film that significantly enhances corrosion resistance and oxidation resistance, effectively resisting the erosion of impurities and moisture in the fuel. The outer shell uses an electrophoretic coating process, achieving a salt spray resistance of over 1000 hours. Even in harsh environments such as high-dust mines and high-humidity wetlands, it maintains excellent heat dissipation performance and a pristine appearance, minimizing heat dissipation efficiency loss due to corrosion.

In terms of safety design, this fuel radiator is equipped with a precise temperature control device that monitors fuel temperature in real time and feeds feedback to the control system. When the fuel temperature rises abnormally, a protection mechanism is triggered promptly to prevent system overheating and damage. Simultaneously, filters are installed at the radiator’s inlet and outlet to effectively filter impurities in the fuel, preventing blockage of the heat dissipation channels and ensuring long-term stable heat dissipation.

When you need to replace the fuel radiator on your XCMG XE2000 excavator, choosing the original product with part number 800152621 ensures efficient heat dissipation for your fuel system. With its superior heat dissipation efficiency, reliable structural performance, and precise adaptability, it safeguards the stable operation of the excavator’s fuel system, reduces equipment failures caused by poor heat dissipation, and allows you to work with peace of mind in various complex construction scenarios, fully accelerating project progress.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318306873 Engine mounting assembly XCMG XE2000 excavator spare parts

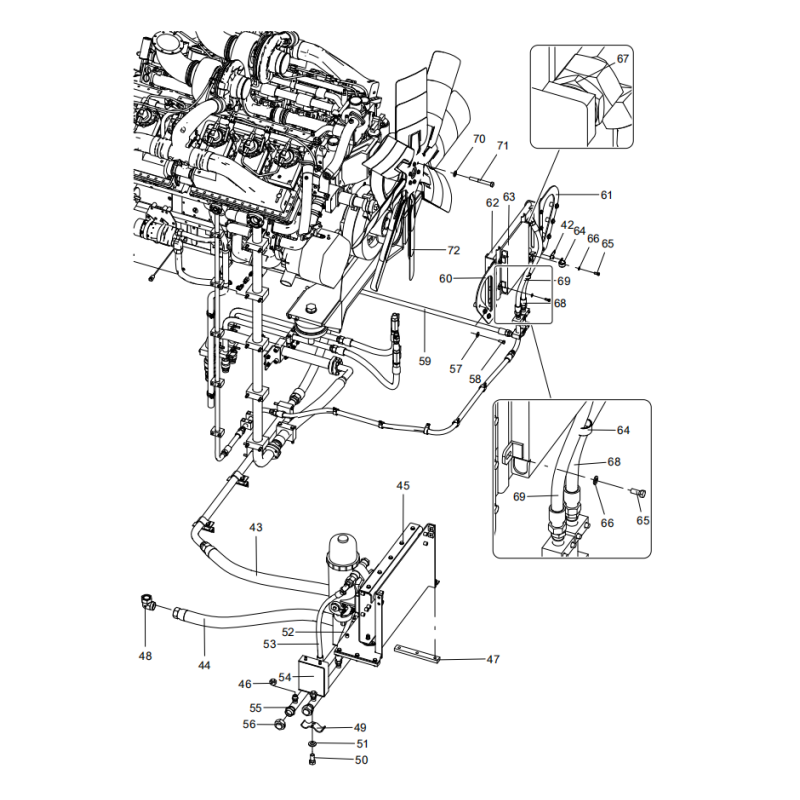

42 318306805 1 BRACKET

43 800171719 1 DIESEL PIPE

44 800166878 1 DIESEL PIPE

45 318300827 1 FUEL FILTER INSTALLATION

46 803177599 4 PLUG

47 318307383 2 PAD

48 803301445 2 CONNECTOR

49 329900503 2 PIPE CLIP

50 805046469 28 BOLT M12×25 GB/T5783-2000

51 805338281 28 WASHER 12 GB/T97.1-2002

52 800175192 1 DIESEL PIPE

53 803419817 1 HOSE ASS’Y

54 318800855 2 STEEL PIPE BRACKET A

55 318800843 2 OIL INLET STEEL PIPE A

56 803173882 2 PLUG

57 329900298 6 THICKENED LARGE WASHER

58 329901414 6 BOLT

59 803419820 1 HOSE ASS’Y

60 318306785 1 BRACKET

61 318306786 1 BRACKET

62 318300819 1 BRACKET

63 800152621 1 FUEL RADIATOR

64 803697900 8 IMPREGNATED HOOP

65 805011330 4 BOLT M10×25 GB/T5783-2000

66 805338279 4 WASHER 10 GB/T97.1-2002

67 800151146 2 CONNECTOR

68 800175156 1 DIESEL PIPE

69 800175154 1 DIESEL PIPE

70 318300796 6 WASHER

71 318300795 6 BOLT

72 800157257 1 FANS