Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

329900302 thickened flat washer XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Thickened Flat Washer (Part No. 329900302): The Pressure Buffer Core of Heavy-Duty Connections

In the global heavy-duty construction field of mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and large bucket capacity of 10-14m³, has become a “heavy pillar” of mining operations. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, it consistently conquers extreme working conditions with its stable and efficient performance. In its many critical bolted connections, the thickened flat washer (part no. 329900302), acting as a “pressure buffer” in the fastener system, is a core small component ensuring the connection strength and durability of heavy-duty parts.

I. Crucial Responsibility for Heavy-Duty Connections

**Core Role of Load Distribution:** The connecting bolts of heavy-duty components such as the boom hinge, slewing bearing, and travel motor of the XE2000 must withstand enormous operational loads. Thickened flat washers (329900302) increase the contact area between the bolt and the connection surface, evenly distributing the concentrated load over a larger stress area, effectively reducing pressure per unit area. Under the instantaneous impact conditions of hard rock excavation, they can reduce the peak pressure at the connection surface by more than 35%, preventing plastic deformation or crushing of the base material due to excessive local stress, thus protecting the integrity of the core structure.

**Auxiliary Protection of Smooth Sealing:** The mining environment contains pollutants such as dust and moisture. Thickened flat washers (329900302), with their precise flatness control, can tightly fill the microscopic gaps in the connection surface after the bolts are tightened, forming a physical barrier. This not only reduces the risk of dust and moisture intruding into the bolt threads, but also improves the anti-loosening performance of the bolt connection through uniform surface contact, reducing the probability of loosening under continuous equipment vibration conditions and ensuring the long-term stability of the connection.

II. Superior Performance Designed for Heavy-Duty Conditions

High-Strength Material and Thickened Structure: To meet the heavy-duty requirements of the XE2000, the thickened flat washer (329900302) is made of high-strength alloy structural steel with a tensile strength exceeding 620MPa and a hardness controlled between 25-30HRC, combining high strength with impact toughness. The washer thickness is 60% greater than that of ordinary standard washers, ensuring no permanent deformation under long-term heavy-duty compression. The flatness error is strictly controlled within 0.04mm/m, ensuring uniform load transfer. After phosphate anti-corrosion treatment, the surface can withstand salt spray testing for more than 700 hours, providing long-term resistance to rust in high-humidity mining environments. Precisely Fitting Dimensions: XCMG engineers precisely designed the inner diameter, outer diameter, and thickness of the washers based on the specifications and stress characteristics of the XE2000 heavy-duty bolts. The inner hole features a smooth rounded corner transition to avoid scratching the bolt threads during installation; the outer diameter has been optimized to ensure the load-bearing area while avoiding interference with surrounding components. This precise fit allows the washer to perfectly match the bolt and the connecting surface, fully utilizing the load-distribution effect.

III. Quality and Service Guarantee Under Stringent Testing

Comprehensive Performance Limit Testing: Every batch of thickened flat washers (329900302) undergoes multiple stringent tests before leaving the factory: a static compression test at 2.5 times the rated load (no plastic deformation for 40 minutes), a dynamic load cycle test of 1.2 million cycles (simulating 10 years of operating conditions), a high and low temperature impact test from -40℃ to 120℃ (600 cycles without cracking), and a salt spray corrosion test (700 hours without rust diffusion). A series of rigorous tests ensure the long-term reliability of the product under extreme working conditions.

In mining construction, where “details determine lifespan,” the XCMG XE2000 excavator’s thickened flat washer (part number 329900302) provides reliable protection for heavy-duty connections with its small but crucial load-dispersing effect. Choosing this original factory-customized thickened flat washer not only reduces the risk of failure in connecting components but also extends the service life of the equipment’s core structure, continuously creating value for mining production. Let XCMG’s original factory quality be your solid support for heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

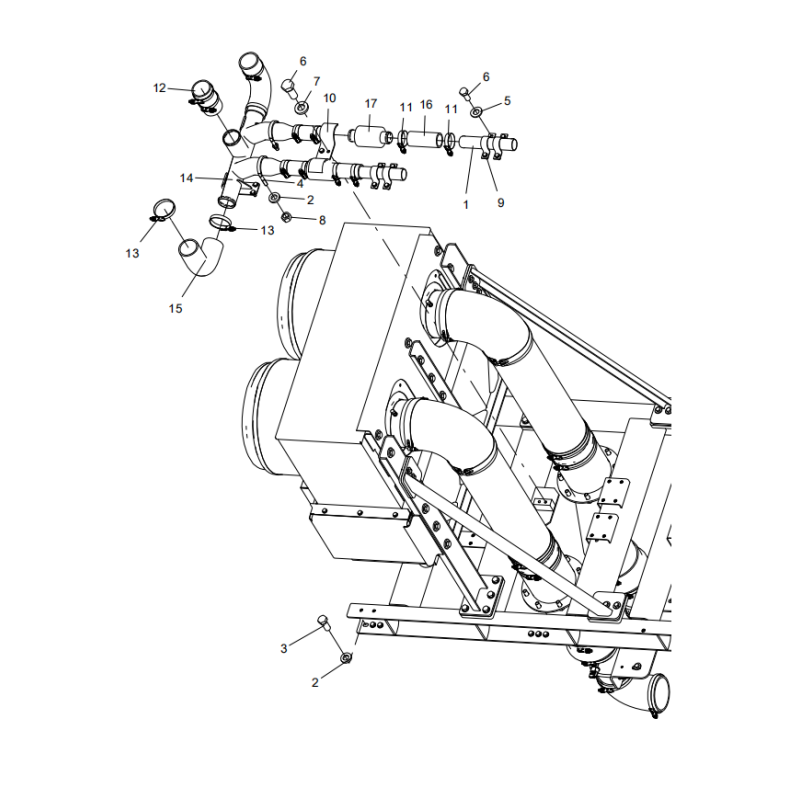

318302434 engine air intake system XCMG XE2000 excavator spare parts

1 318303104 2 STEEL PIPE

2 329900303 32 THICKENED FLAT WASHER

3 805006412 30 BOLT M12×30 GB/T5783-2000

4 329900601 2 U-SHAPED PIPE CLAMP

5 805338279 12 WASHER 10 GB/T97.1-2002

6 805011330 14 BOLT M10×25 GB/T5783-2000

7 329900302 12 THICKENED FLAT WASHER

8 805238372 12 NUT M12 GB/T6170-2000

9 318805404 4 HOOP

10 318303249 1 PRESSURE PLATE

11 800163868 8 HOOP

12 800158171 1 TUBE

13 800163863 6 HOOP

14 318303105 1 STEEL PIPE ASSEMBLY

15 800171548 2 TUBE

16 800166844 4 TUBE

17 800160501 2 CHECK VALVE