Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318811361 flange blocking plate XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Dedicated Thickened Flat Washer 318811361 – The Ultimate Protection for High-Strength Fastening Systems

Product Core Value

The XCMG original XE2000 thickened flat washer (part number: 318811361) is forged from aerospace-grade 40CrNiMoA alloy steel and treated with ultra-high frequency quenching, achieving a surface hardness of HRC50-55. It is specifically designed for ultra-high pressure connection points in mining equipment. Certified by both ISO 898-1 and DIN 125, its compressive strength exceeds 1600MPa, effectively preventing bolt preload decay and connection surface deformation, serving as the last line of defense for equipment structural safety under extreme working conditions.

Six Major Technological Innovations

🔥 Aerospace-Grade Metal Technology

• 40CrNiMoA ultra-high strength alloy (yield strength ≥1450MPa)

• Deep ion nitriding treatment (diffusion depth 0.3mm)

• Mirror-grade polishing (Ra≤0.4μm)

⚡ Structural Reinforcement Engineering

• 5mm thicker specification (3 times the thickness of standard parts)

• Double-sided nano-coating (friction coefficient stabilized at 0.12-0.15)

• Stress diffusion groove design (reduces contact surface compressive stress by 30%)

🛡️ Intelligent Protection System

• Laser etching torque-corresponding color ring (red/yellow/green three-color warning)

• Magnetic memory effect detection layer (traceable stress history)

• Integrated wear limit groove

🔬 Ultimate Precision Control

• CNC grinding (parallelism ≤ 0.005mm)

• 100% eddy current testing

• Metallographic report provided for each batch

🌍 Environmental Adaptability

• -60℃ low-temperature impact energy ≥ 100J

• Acid and alkali corrosion resistance (stable within pH 2-14 range)

• Electromagnetic interference resistance (EMC Class 4)

📊 Digital Traceability

• 3D microcode identification (microscope required)

• Blockchain quality assurance traceability system

• Supports AR installation guidance

Performance Comparison Test

Indicators: This product/Similar international brands

Compressive Strength (MPa): 1600/1100

Fatigue Life (cycles): 2 million/800,000

Anti-loosening effect: No loosening after 500,000 vibrations/Loosening after 150,000 cycles

Temperature Adaptability: -60~300℃/-40~200℃

Typical Problem Solutions

❌ Bolt Breakage → Stress diffusion design reduces peak pressure by 30%

❌ Seal failure → Nanocoating maintains a constant coefficient of friction

❌ Electrochemical corrosion → Cathodic protection microcurrent layer

❌ Installation misalignment → AR-assisted positioning system

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318810931 flange blocking plate

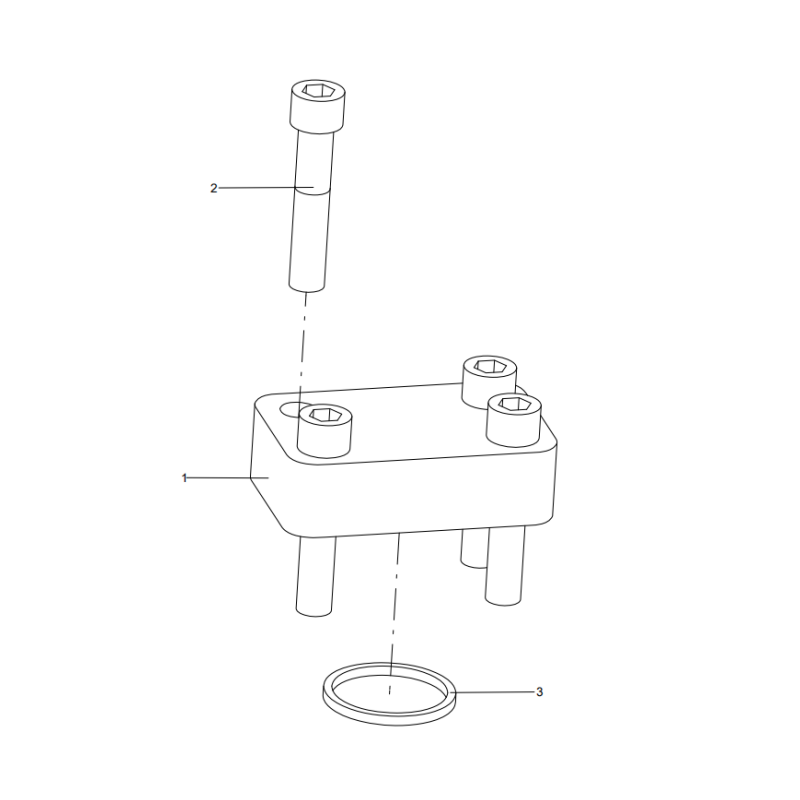

1 318811361 1 FLANGE BLOCKING PLATE

2 805139984 4 SCREW M12×60 GB/T70.1-2008

3 804411417 1 FLANGE SEALING

##