Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307815 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Steel Pipe Assembly (318307815): The Backbone of High-Pressure Transmission in the Hydraulic System

In the hydraulic power transmission network of the XE2000 large mining excavator, the steel pipe assembly is the “rigid artery” that carries the stable delivery of high-pressure hydraulic oil. Its structural strength and flow performance directly determine the overall hydraulic efficiency and operational safety of the machine. XCMG’s original steel pipe assembly (part number: 318307815) is specially customized and developed for the complex piping layout of this model. With its superior pressure resistance, precise manufacturing process, and deep original factory compatibility, it becomes the core support for the efficient transmission of high-pressure hydraulic oil.

High-strength pipe forging ensures ultimate pressure resistance

The XE2000 excavator’s hydraulic system operates at pressures up to 35MPa, with instantaneous impact pressures reaching 45MPa, placing stringent requirements on the structural strength of the steel pipes. This steel pipe assembly is manufactured using high-pressure seamless alloy steel pipe (material 20# steel). After cold rolling strengthening treatment, the pipe wall’s tensile strength is increased to ≥570MPa, yield strength to ≥360MPa, and burst pressure to over 112MPa, far exceeding the actual working pressure requirements of the system. A differentiated wall thickness design (3.3-5.8mm wall thickness corresponding to pipe diameters of Φ19-Φ58) is adopted to address the pressure distribution characteristics of different pipeline locations. This ensures pressure resistance and safety while achieving lightweight optimization, reducing the weight of a single assembly by 10% compared to traditional steel pipes, effectively reducing vibration load and energy loss during pipeline operation.

Precision forming process significantly reduces flow resistance

The smooth transmission of hydraulic oil directly affects the system’s response speed, placing extremely high demands on the dimensional accuracy and inner wall quality of the steel pipe. The 318307815 steel pipe assembly adopts a cold-drawn precision forming process, with the outer diameter tolerance strictly controlled within ±0.08mm and the wall thickness uniformity error ≤4%, ensuring precise pipeline connection sealing. The inner wall undergoes precision honing, achieving a surface roughness ≤Ra0.6μm, effectively reducing hydraulic oil flow resistance and pressure loss by over 19% compared to ordinary steel pipes. The bends are formed using a five-axis CNC hydraulic pipe bending machine, with a bending radius error ≤0.8mm and an inner wall thickness reduction ≤8%, avoiding localized turbulence caused by bend deformation and ensuring stable hydraulic oil flow in complex pipeline layouts, improving system response speed by over 13%.

Precise factory layout adaptation, seamless pipeline integration

As a core transmission component of the XE2000 excavator’s hydraulic system, the routing and connection of this steel pipe assembly have been fully optimized by the factory. Based on the machine’s three-dimensional pipeline simulation design, the bending angle and installation points of the steel pipe perfectly match the hydraulic system layout requirements, achieving precise interface docking with core components such as the main pump (adapter part number 804001727), main valve, and cylinder. The pipe clamp fixing spacing has been calibrated through vibration testing and perfectly matches the pipe clamp assembly (adapter number 318307802). It maintains pipeline stability even under high-frequency vibration conditions, avoiding frictional interference with other components. The steel pipes in the assembly are rigidly connected via transition joints, with an overall pipeline coaxiality error ≤0.16mm/m. This ensures leak-free transmission of high-pressure hydraulic oil in complex pipelines, eliminating pressure loss and pipeline wear caused by improper layout.

Multi-layer anti-corrosion protection, excellent weather resistance in extreme environments

Dust, moisture, oil, and chemical corrosion in mining environments pose severe challenges to the weather resistance of steel pipes. This steel pipe assembly employs a multi-layer anti-corrosion treatment process: the inner wall undergoes phosphating for rust prevention, forming a uniform protective film to isolate hydraulic oil corrosion; the outer wall is sandblasted and rust-removed, then coated with an epoxy primer (thickness ≥70μm), followed by an oil-resistant and wear-resistant topcoat (thickness ≥90μm), achieving an overall salt spray resistance of over 1250 hours. Within a temperature range of -35℃ to 85℃, the physical properties of the pipe and the stability of the anti-corrosion coating remain unchanged, and there will be no coating cracking or corrosion due to alternating hot and cold temperatures. Field verification in mines has shown that after long-term use in dusty and high-humidity environments, there is no scaling on the inner wall of the pipe and no rust on the outer wall, ensuring the cleanliness of the hydraulic oil and the stability of the pipe flow performance.

Full-process quality control, multiple guarantees of safety performance

XCMG implements stringent full-lifecycle quality control for the 318307815 steel pipe assembly. From raw material intake to finished product delivery, it undergoes 19 professional tests. Each steel pipe passes a 100% hydrostatic test (52MPa pressure holding for 5 minutes without leakage), eddy current testing, and dimensional accuracy inspection to ensure the absence of quality defects such as sand holes and cracks. After assembly, the assembly undergoes an overall sealing test and a pressure pulse test (160,000 cycles) to ensure reliable sealing even under high-frequency pressure fluctuations. The product complies with ISO 4019 hydraulic steel pipe standards and mining equipment safety specifications, providing multiple safety redundancies for high-pressure operation of the hydraulic system.

XCMG XE2000 excavator steel pipe assembly (part number 318307815) – Utilizing high-strength pipes to withstand extreme high pressure, precision manufacturing processes to ensure efficient flow, and original equipment manufacturer (OEM) compatibility for system synergy, it is an indispensable high-pressure transmission backbone for the hydraulic system of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

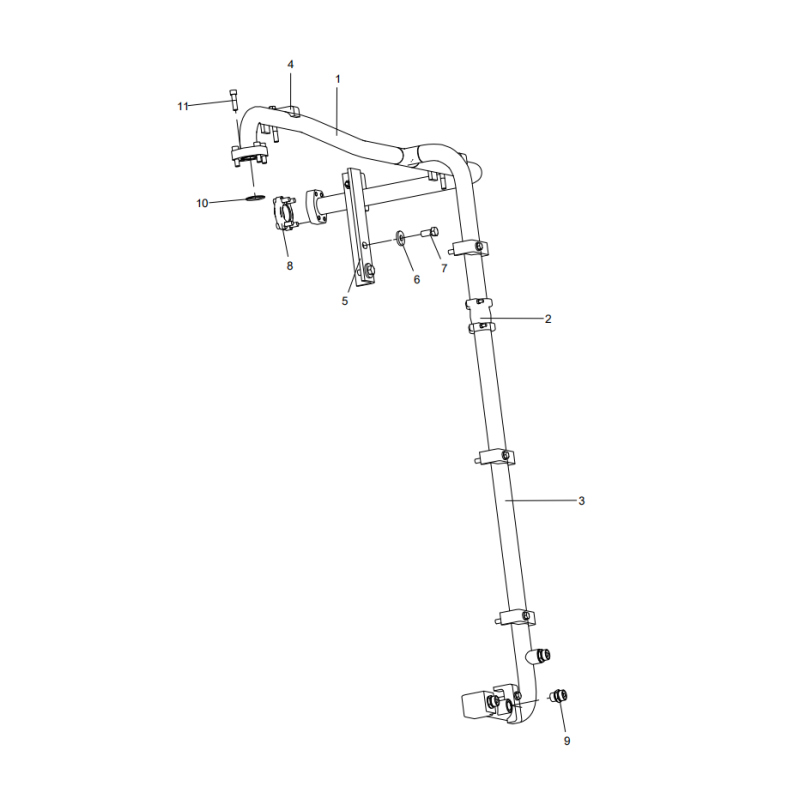

318307815 steel pipe assembly

1 318811022 1 TRANSIT JOINT

2 803012821 1 CONNECTOR

3 803107270 1 CONNECTOR

4 803172186 2 PLUG

5 803103340 1 CONNECTOR

##