Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307802 pipe clamp assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Pipe Clamp Assembly (318307802): The Core of Stable Piping System Fixation

In the complex piping system of the XE2000 large mining excavator, the pipe clamp assembly is a key component ensuring the stable fixation of hydraulic and air lines. Its performance directly affects the operational safety and service life of the piping system. XCMG’s original pipe clamp assembly (part number: 318307802) is specially customized and developed for the piping layout of this model. With its strong clamping ability, precise positioning performance, and excellent weather resistance, it provides a solid guarantee for the stable operation of the piping system.

High-strength structural design ensures reliable and secure clamping

The high-frequency vibrations generated by the XE2000 excavator during heavy-duty operations place stringent requirements on the stability of the piping fixation. This pipe clamp assembly is integrally stamped from high-strength alloy steel plate (Q345B), with a tensile strength ≥520MPa and a yield strength ≥345MPa. The clamping parts are reinforced, with a surface hardness of HB180-220. The rated clamping force of a single pipe clamp can reach over 8kN. The contact area between the pipe clamp and the pipeline adopts an arc-shaped design, achieving a fit of over 95%. Combined with high-strength bolts for fastening (pre-tightening torque error ≤5%), it effectively prevents pipeline loosening and displacement under high-frequency vibration. In whole-machine vibration testing (10-2000Hz), the pipe clamp assembly showed no deformation or loosening, ensuring the pipeline remains in the preset installation position and avoiding friction wear and interface leakage caused by pipeline shaking.

Precise Dimension Control, Adapting to Pipeline Layout Requirements

The complex layout of pipeline systems requires pipe clamps with precise dimensions and positioning performance. The 318307802 pipe clamp assembly is manufactured using CNC stamping and laser cutting processes, with key dimensional tolerances controlled within ±0.5mm and mounting hole positional errors ≤0.3mm, perfectly matching the layout design of the XE2000 excavator’s piping system. For pipes of different diameters (Φ16-Φ60mm), the pipe clamps employ a modular design, achieving precise fit by replacing different specifications of rubber bushings. The bushing inner diameter tolerance is ≤±0.2mm, ensuring a tight fit with the pipe. The installation spacing of the pipe clamps has been optimized through dynamic simulation, creating effective damping on the vibration transmission path, reducing pipe resonance and lowering the risk of pipe fatigue damage.

Original Factory Layout Adaptation, Safe and Coordinated System Operation

As a core fixing component of the XE2000 excavator’s piping system, the installation position and clamping method of this pipe clamp assembly have been fully calibrated by the original factory. Based on three-dimensional piping simulation analysis of the entire machine, the installation points of the pipe clamps avoid high-stress areas, ensuring that no additional stress is generated on the pipes during equipment movement. The pipe clamps are fully compatible with hydraulic hose assemblies (fitter number 804414139) and steel pipe assemblies (fitter number 318307798) in terms of fit dimensions. A layered fixing design allows for the orderly arrangement of different types of pipelines, avoiding frictional interference between them. Full-machine operation testing has verified that the pipe clamp assembly can effectively control pipeline amplitude ≤0.5mm, significantly reducing fatigue damage to pipeline interfaces and ensuring the safe operation of the pipeline system.

All-environment weather resistance protection extends service life. Dust, water vapor, oil, and temperature variations in the mining environment pose a challenge to the weather resistance performance of the pipe clamp assembly. This pipe clamp assembly employs a multi-layer anti-corrosion treatment process: the metal parts undergo galvanizing and passivation (zinc layer thickness ≥8μm), followed by spraying with oil-resistant and rust-proof paint (thickness ≥60μm), achieving salt spray resistance for over 720 hours; the rubber bushing is made of oil-resistant nitrile rubber, maintaining good elasticity with a volume change rate ≤5% and a hardness change ≤10 Shore A after immersion in hydraulic oil at 120℃ for 1000 hours. Within a temperature range of -40℃ to 80℃, the structural performance and clamping force of the pipe clamp assembly remain stable without attenuation, preventing metal corrosion or rubber aging due to temperature fluctuations, extending its service life by more than 60% compared to ordinary pipe clamps.

Rigorous quality testing ensures stable and reliable performance

XCMG implements full-process quality control for the 318307802 pipe clamp assembly, requiring 15 professional tests from raw material intake to finished product delivery. Each batch of pipe clamps undergoes rigorous testing, including clamping force testing (8kN pressure holding for 1 hour without deformation), vibration testing (10-3000Hz, 20G acceleration), and salt spray testing, ensuring no structural defects or performance degradation. The rubber bushings undergo specialized tests such as oil aging resistance and high/low temperature cycling to ensure stable performance under harsh working conditions. The products comply with ISO 1436 pipe fixing standards and mining equipment safety regulations, providing multiple layers of protection for the stable operation of the pipeline system.

The XCMG XE2000 excavator pipe clamp assembly (part number 318307802) – with its high-strength structure ensuring secure clamping, precise dimensions adapting to pipeline layouts, and comprehensive protection extending service life, it is an indispensable and stable fixing core for the pipeline system of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

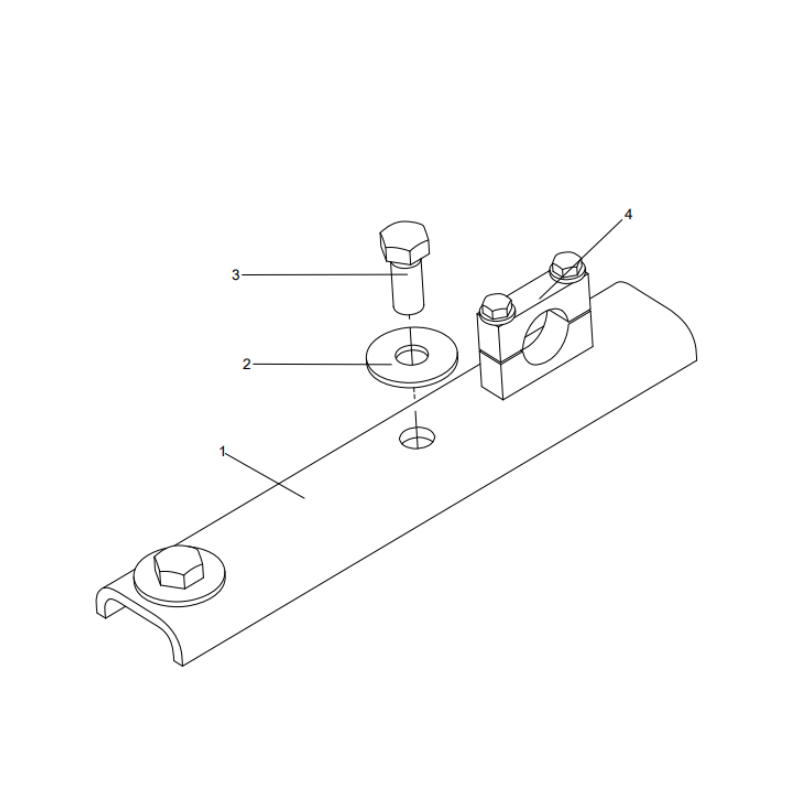

318307802 pipe clamp assembly

1 318307801 1 BRACKET

2 805338318 2 WASHER 24 GB/T96.1-2002

3 805046595 2 BOLT M24×55 GB/T5783-2000

4 318006991 1 PIPE CLAMP ASSEMBLY

##