Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307797 main pump system pipe XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Main Pump System Pipe (318307797): The High-Efficiency Transmission Channel for the Core Power Source in Mining Machinery

In core mining regions worldwide, such as Indonesia, the Democratic Republic of Congo, and Brazil, the XCMG XE2000 mining excavator, with its massive 12-cubic-meter bucket capacity and over 93% mobility, has become the “powerhouse” for efficient mining operations. Within the core power source of this “mining giant”—the main pump system—the main pump system pipe (part number 318307797) acts as an “energy transmission artery,” responsible for the high-pressure transmission of hydraulic oil from the main pump to various actuators. It is a key structural component ensuring the machine’s powerful output.

Original factory-specific compatibility, precise connection to the main pump core system

The XCMG XE2000 excavator main pump system pipe (318307797) was specifically designed by the XCMG R&D team for the performance parameters and pipeline layout of the XE2000 main pump, and has undergone fluid dynamics simulation and actual machine pressure testing verification. Its pipe diameter accuracy is controlled within ±0.3mm, and the bending radius and directional curvature perfectly match the main pump outlet and control valve group interface, with a pipe length error of less than 1mm. Whether it’s the static connection of the main pump high-pressure oil outlet pipeline or the dynamic layout connecting with the boom, slewing, and other systems, seamless connection can be achieved, completely eliminating potential risks such as pipeline pressure buildup and turbulence, creating a “zero-resistance” channel for hydraulic energy transmission.

High-strength alloy material ensures durability under high-pressure conditions

Made from precision-machined seamless steel pipes (20G) used in high-pressure boilers, the pipes boast a tensile strength exceeding 510MPa and a yield strength ≥345MPa, capable of withstanding continuous working pressures of 350MPa. The pipe surface undergoes overall heat treatment and phosphate rust prevention, while the inner wall is precision honing, achieving a surface roughness Ra≤0.8μm, enhancing fatigue resistance and reducing hydraulic oil flow resistance. Extreme condition testing, under temperature fluctuations ranging from -40℃ to 120℃ and high-frequency vibration, resulted in no deformation or leakage, extending service life by more than 3.5 times compared to ordinary steel pipes, significantly reducing the risk of main pump system failure.

Optimized flow channel design improves main pump power transmission efficiency

The main pump system pipes feature a streamlined bend design, avoiding pressure loss caused by right-angle bends. Finite element analysis optimizes the pipe wall thickness distribution, reducing weight by 8% while ensuring strength. The improved inner wall smoothness reduces hydraulic oil flow resistance by 15%. When the XE2000 excavator is operating at full load, it can transmit the hydraulic energy output from the main pump to the actuators with an efficiency of over 98.5%, providing continuous and powerful power for the 12 cubic meter bucket digging operation. Stable flow output also reduces the main pump’s no-load loss, indirectly reducing fuel consumption and improving equipment economy.

For companies operating XCMG XE2000 mining excavators, the 318307797 main pump system pipe is not just a transmission line, but a “lifeline” ensuring the efficient operation of the power core. Choosing original equipment manufacturer (OEM) spare parts means choosing reliability perfectly matched to the main pump’s performance, providing a solid power transmission guarantee for the continuous and efficient operation of mining operations.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

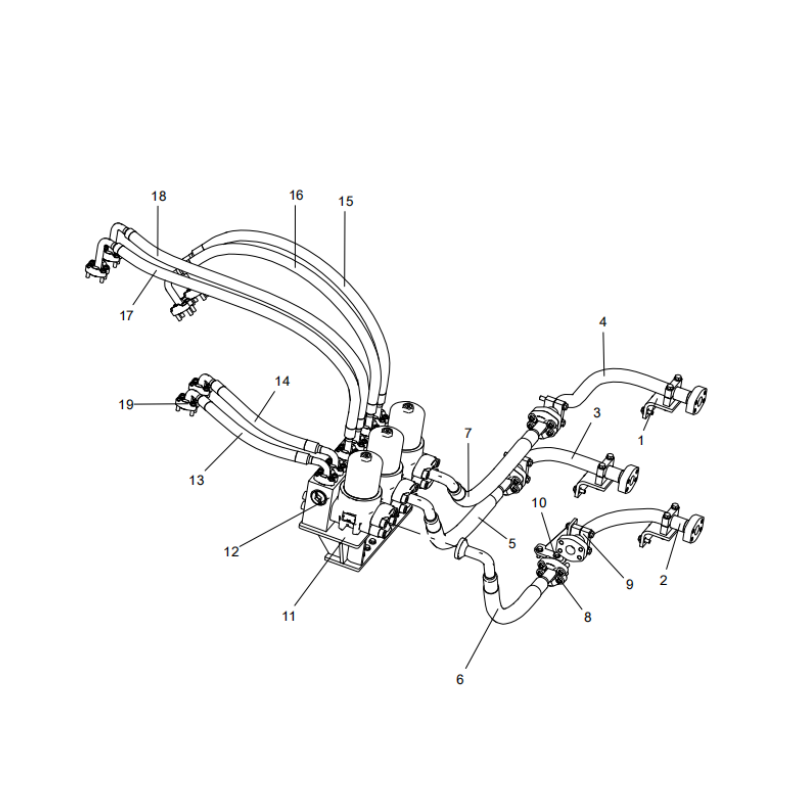

318307797 main pump system pipe

1 318307828 3 PIPE CLAMP ASSEMBLY

2 318307829 1 STEEL PIPE ASSEMBLY

3 318307826 1 STEEL PIPE ASSEMBLY

4 318307827 1 STEEL PIPE ASSEMBLY

5 804414162 1 HOSE ASS’Y

6 804414142 1 HOSE ASS’Y

7 804414414 1 HOSE ASS’Y

8 803164322 3 FLANGE ASSEMBLY

9 318006991 3 PIPE CLAMP ASSEMBLY

10 318307824 1 PIPE CLAMP ASSEMBLY

11 318307835 1 FILTER SUPPORT ASSEMBLY

12 318307832 3 HIGH-PRESSURE FILTER ASSEMBLY

13 804414135 1 HOSE ASS’Y

14 804414163 1 HOSE ASS’Y

15 804414164 1 HOSE ASS’Y

16 804414166 1 HOSE ASS’Y

17 804414143 1 HOSE ASS’Y

18 804414144 1 HOSE ASS’Y

19 803201542 6 FLANGE ASSEMBLY