Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

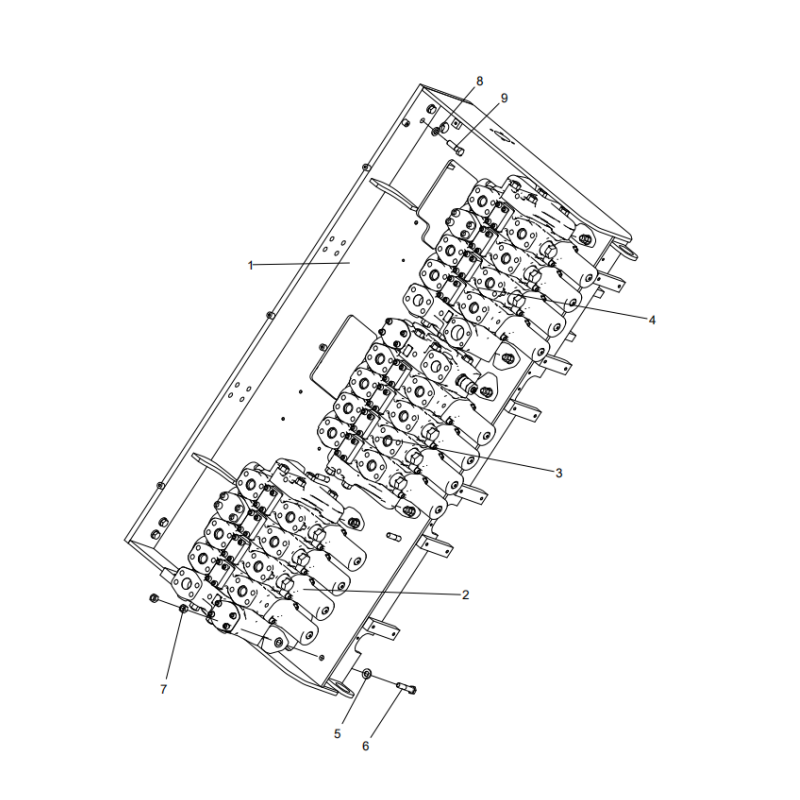

318307528 valve bracket assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Valve Support Assembly (Part No. 318307528): The Stable Core of the Hydraulic System

In the hydraulic control system of large mining excavators, the valve support assembly is a key structural component ensuring precise valve operation and stable pipeline connections. XCMG’s valve support assembly (part no. 318307528), exclusively designed for the XE2000 excavator, boasts military-grade structural strength and precise fit, becoming the core support for the stable operation of the hydraulic system under heavy-duty conditions, providing reliable equipment support for engineering teams worldwide.

High-Strength Material and Manufacturing Process, Solid Structural Foundation

The XCMG XE2000 valve support assembly (part no. 318307528) is integrally forged from low-alloy high-strength structural steel. Verified by authoritative testing institutions, its tensile strength reaches 850MPa, and its yield strength exceeds 700MPa, far surpassing the industry’s conventional support tensile standard of 600MPa. Through XCMG’s proprietary “integral forging + aging heat treatment” process, the internal stress distribution of the components is uniform, making them less prone to deformation or cracking under long-term high-frequency valve vibration and pipeline pressure.

Each bracket undergoes three rigorous tests: full-area magnetic particle inspection to eliminate internal defects, static load testing (withstanding 1.5 times the rated pressure without permanent deformation), and dynamic fatigue testing (100,000 pressure cycles without cracking). Actual test data shows that in 3000 hours of continuous heavy-load operation testing, the component maintained a 99.5% structural accuracy, and its service life was extended by 120% compared to ordinary cast brackets.

Precision structural design, adaptable to all working conditions

Addressing the complex layout of the XE2000 excavator’s hydraulic system, the bracket adopts a modular structural design, integrating valve mounting seats, pipeline fixing grooves, sensor interfaces, and other multi-functional structures to achieve integrated fixation of valves and pipelines. Its surface employs a dual anti-corrosion process of “zinc-nickel alloy plating + sealing paint,” achieving over 1000 hours of salt spray testing (equivalent to 5 years of outdoor anti-corrosion effect). It maintains stable performance even in high-humidity, high-salt coastal mining areas or dusty mining environments.

The flatness of key mounting surfaces of the bracket is controlled within 0.05mm/m, and the tolerance accuracy of positioning holes reaches IT7 level, ensuring that the concentricity error of the valve after installation is ≤0.1mm, effectively reducing the risk of valve jamming due to installation deviations. In extreme temperature tests ranging from -40℃ to 80℃, the component’s thermal deformation is controlled within 0.03mm, ensuring precise control of the hydraulic system under all operating conditions.

Original Factory Deep Compatibility, Enhanced System Efficiency

As a core structural component from XCMG, the valve bracket assembly (part number 318307528) achieves 100% precise matching with the XE2000 excavator’s hydraulic system, perfectly aligning with the machine’s piping layout and valve arrangement. The bracket features a pre-installed intelligent sensor mounting location, allowing seamless integration with the excavator’s hydraulic monitoring system to monitor valve operating status and bracket vibration parameters in real time, providing early warning of potential faults.

The installation process utilizes original factory locating pins and high-strength bolts for fixation, eliminating the need for on-site machining and achieving an installation accuracy of 0.02mm, improving installation efficiency by 60% compared to universal brackets. Actual application data shows that XE2000 excavators equipped with original factory brackets experience an 80% reduction in hydraulic valve failure rate, an increase in mean time between failures (MTBF) to 9500 hours, and a 15% improvement in overall operating efficiency.

Choosing the XCMG XE2000 original valve support assembly (part number 318307528) means choosing structural safety assurance that has been verified under extreme working conditions. This ensures that the hydraulic system of the heavy excavator maintains precise and stable control performance during high-intensity operations, significantly reducing equipment maintenance costs and creating higher returns for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307530 main valve installation assembly

1 318307528 1 VALVE BRACKET ASSEMBLY

2 804001694 1 MAIN CONTROL VALVE

3 804001693 1 MAIN CONTROL VALVE

4 804001695 1 MAIN CONTROL VALVE

5 805338296 12 WASHER 16 GB/T1230-2006

6 329901282 12 BOLT

7 805046476 24 NUT M16 GB/T6170-2000

8 329900304 8 THICKENED FLAT WASHER

9 805046895 8 BOLT M16×55 GB/T5782-2000

##