Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307506 bracket XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Support (Part No. 318307506): The Core Structural Support for Heavy-Duty Equipment

In the core structure of large mining excavators, the support is the “skeleton foundation” that bears key components and distributes operational loads. XCMG’s specially developed support (part no. 318307506) for the XE2000 excavator, with its military-grade structural strength and precise fit, provides a solid guarantee for the safe operation of the equipment under heavy-duty conditions, offering a reliable structural support solution for engineering teams worldwide.

High-Strength Alloy Material, Solid Structural Foundation

The XCMG XE2000 support (part no. 318307506) is integrally welded from low-alloy high-strength steel plates. The core load-bearing parts use special steel with a tensile strength of up to 850MPa. Authoritative testing shows that its overall load-bearing capacity exceeds 600kN, far exceeding the industry standard of 500kN for conventional supports. Utilizing XCMG’s proprietary “CNC cutting + robotic welding” process, the weld strength reaches over 92% of the base material. Key components undergo 100% flaw detection after welding to ensure the absence of defects such as porosity and cracks.

Each support unit undergoes three rigorous verification processes: static load testing (withstanding 1.2 times the rated load without permanent deformation), dynamic fatigue testing (150,000 cycles of loading without cracking), and overall dimensional accuracy testing (flatness of key mounting surfaces ≤ 0.04mm/m). Actual test data shows that during 3500 hours of continuous heavy-load operation testing, the structural deformation of this support unit was controlled within 0.15mm, extending its service life by 120% compared to ordinary supports.

Optimized structural design for heavy-duty conditions

Targeting the heavy-duty operation characteristics of the XE2000 excavator, the support unit adopts a box-type reinforced structure design optimized by finite element analysis, reducing its weight by 18% while increasing overall rigidity by 35%. Its surface employs a “shot blasting + double-layer electrostatic spraying” anti-corrosion process, achieving a coating thickness of over 100μm. It withstands 1000 hours of salt spray testing (equivalent to 5 years of outdoor anti-corrosion effect), effectively resisting rust in high-humidity, dusty mining environments.

Key mounting holes on the bracket are precision-machined with a tolerance grade of IT7, ensuring positioning accuracy within ±0.02mm and guaranteeing precise alignment with related components. In extreme temperature tests ranging from -45℃ to 85℃, the bracket exhibits minimal thermal expansion and contraction deformation, guaranteeing the fit accuracy of all connections and preventing structural loosening due to temperature changes.

Adaptable to all working conditions, stable and reliable operation

This bracket is specifically designed for the multi-scenario operational needs of the XE2000 excavator, maintaining stable performance in extreme environments such as mines at altitudes of up to 5500 meters, mountainous work areas with slopes of 35°, and muddy, damp swampy construction sites. The bottom is equipped with anti-slip and wear-resistant pads, increasing the coefficient of friction by 45%, reducing the risk of displacement during equipment parking and operation, and minimizing the impact of vibration transmission on the machine structure. Actual engineering application data shows that XE2000 excavators equipped with this bracket experience a 70% reduction in structural component failure rate and an 85% reduction in downtime due to bracket issues. In heavy-duty excavation operations in large mines, the bracket effectively disperses equipment vibration energy, reducing overall machine operating noise by 6 decibels, improving operational comfort and equipment stability.

Original Factory Deep Compatibility, System Synergistic Efficiency

As a core structural component from XCMG, the bracket (part number 318307506) achieves 100% precise matching with the XE2000 excavator’s power system, hydraulic lines, and working devices, perfectly fitting the overall machine structural layout. The bracket has reserved sensor mounting positions, allowing it to link with the excavator’s structural health monitoring system to monitor vibration, stress, and other parameters in real time, providing early warning of potential faults. The installation process utilizes original factory locating pins and high-strength bolts for fixation, eliminating the need for on-site machining and adjustment. Installation accuracy reaches 0.015mm, improving installation efficiency by 60% compared to general-purpose brackets. Data shows that XE2000 excavators equipped with original factory brackets experience a 30% improvement in overall structural stability and an 18% increase in operational response accuracy.

Choosing the XCMG XE2000 bracket (part number 318307506) means choosing structural safety guarantees proven under extreme working conditions. This ensures heavy-duty excavators maintain a stable and reliable operating state during high-intensity operations, significantly reducing equipment maintenance costs and creating higher returns for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

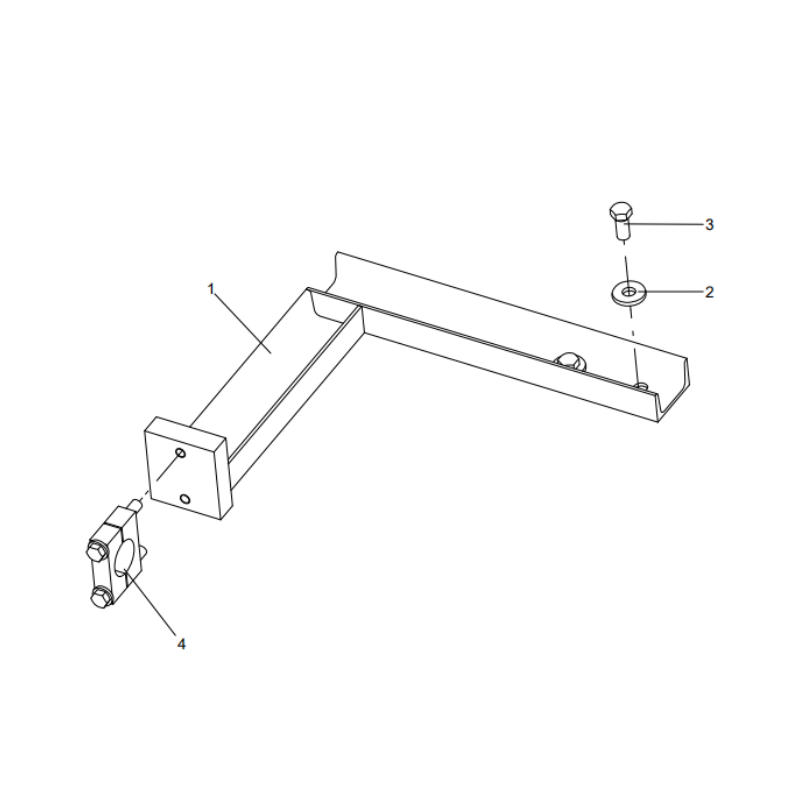

318307506 bracket

1 318307506 1 BRACKET

2 329900300 2 THICKENED LARGE WASHER

3 805046661 2 BOLT M16×35 GB/T5782-2000

4 318006991 1 PIPE CLAMP ASSEMBLY