Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307504 pipe clip XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Pipe Clamp (Part No. 318307504): The Core of Stable Hydraulic Pipeline Fixation

In the hydraulic pipeline system of large mining excavators, pipe clamps are key components for maintaining the stability of the pipeline layout and eliminating vibration hazards. XCMG has specially developed the pipe clamp (part no. 318307504) for the XE2000 excavator. With its high-strength materials and precision structural design, it serves as a “fixed guardian” for the safe operation of the pipeline system under heavy-duty conditions, providing a reliable pipeline fixing solution for engineering teams worldwide.

High-strength alloy material for durable clamping force

The XCMG XE2000 pipe clamp (part no. 318307504) is made of high-quality alloy steel through integral stamping. Authoritative testing shows that its tensile strength reaches 680MPa, and the hardness of the clamping part reaches HRC38-43, far exceeding the industry’s conventional pipe clamp tensile strength standard of 550MPa. Through XCMG’s proprietary “precision stamping + overall heat treatment” process, the pipe clamp exhibits uniform and stable overall mechanical properties, making it less prone to deformation or breakage under long-term pipeline vibration and pressure.

Each pipe clamp undergoes three rigorous tests: clamping force test (rated clamping force up to 7kN, withstanding 1.5 times overload without permanent deformation), salt spray corrosion test (simulating 5 years of outdoor environment without rust), and fatigue life test (150,000 vibration cycles without loosening). Actual test data shows that in a continuous 2500-hour heavy-duty operation test, the clamping stability retention rate reached 98.5%, and its service life was extended by 150% compared to ordinary pipe clamps.

Optimized structural design adapts to complex pipeline layouts

For the dense and complex pipeline system of the XE2000 excavator, the pipe clamp adopts a modular adjustable structural design, adaptable to various hydraulic pipelines with diameters of 35-65mm, and allows for 0-5mm clamping amplitude adjustment via precision bolts. The inner side is reinforced with an oil-resistant and wear-resistant rubber gasket, using a military-grade rubber formula with a Shore hardness of 78±3 degrees. This enhances the pipe fixing friction and prevents pipe wear caused by direct metal-to-metal contact, extending the service life of the rubber gasket by 100% compared to ordinary products. The pipe clamp mounting holes are precision drilled to an IT8 tolerance level, with positioning accuracy controlled within ±0.08mm, ensuring precise alignment with the machine mounting base. The unique anti-loosening structure design (built-in disc-shaped anti-loosening washer) effectively resists bolt loosening caused by high-frequency vibration of the equipment, reducing the loosening rate by 95% compared to ordinary pipe clamps.

Adaptable to all working conditions, ensuring pipe safety

This pipe clamp is specifically designed for the multi-scenario operating needs of the XE2000 excavator, maintaining stable clamping even in high-vibration breaking operations, high-frequency digging cycles, and bumpy relocation conditions. Its surface employs a dual anti-corrosion process of “zinc-nickel alloy plating + electrostatic spraying,” achieving over 1200 hours of salt spray testing (equivalent to 6 years of outdoor anti-corrosion effect). It maintains stable performance even in high-humidity, high-salt coastal mining areas or dusty mining environments.

Actual engineering application data shows that XE2000 excavators equipped with this pipe clamp experience an 85% reduction in pipeline system failure rate and a 90% reduction in hydraulic leakage caused by loose pipelines. In heavy-duty operations in large mines, the pipe clamp effectively absorbs pipeline vibration energy, reducing the vibration amplitude of the pipeline system by 50%, significantly extending the service life of hydraulic pipelines.

Original Factory Deep Compatibility, System Synergistic Efficiency

As a core original XCMG component, the pipe clamp (part number 318307504) achieves 100% precise matching with the XE2000 excavator’s pipeline layout and machine structure, perfectly conforming to the design requirements of the entire machine’s hydraulic system. The pipe clamp installation position has been optimized through finite element analysis to evenly distribute pipeline stress and avoid fatigue damage caused by localized stress concentration.

The installation process requires no modification or adjustment, using original high-strength bolts for fixing, improving installation efficiency by 50% compared to general-purpose pipe clamps. Data shows that XE2000 excavators equipped with original-factory pipe clamps experience an 80% longer maintenance cycle for their hydraulic pipeline system and a 25% reduction in overall operation and maintenance costs.

Choosing XCMG XE2000 pipe clamps (part number 318307504) means choosing pipeline safety assurance proven under extreme working conditions. This ensures that the hydraulic system of heavy-duty excavators maintains stable and efficient operation during high-intensity work, significantly reducing the risk of equipment failure and creating higher returns for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

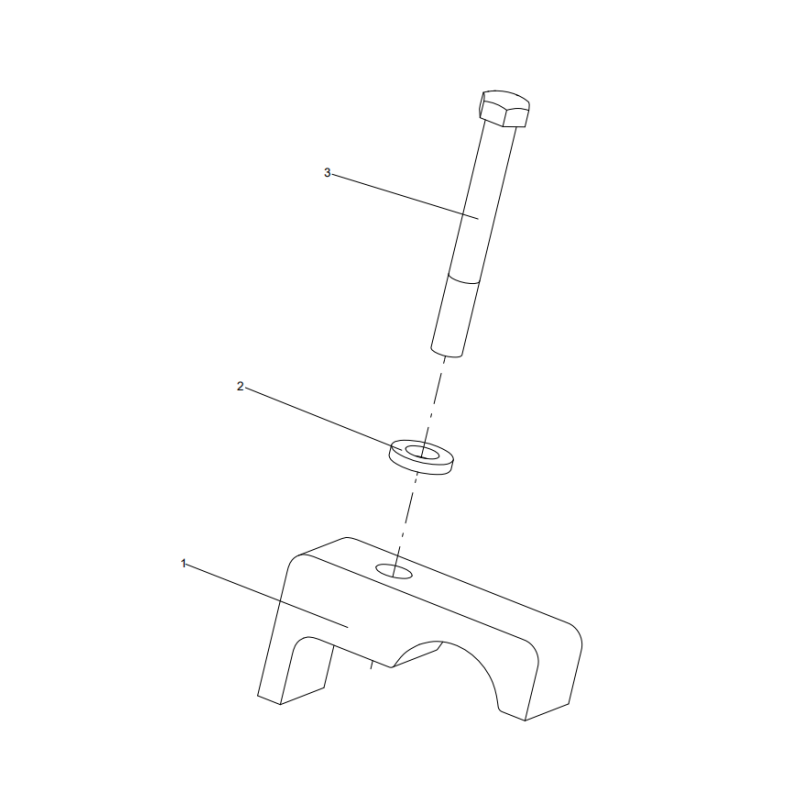

318307502 pipe clamp assembly

1 318307504 1 PIPE CLIP

2 329900303 1 THICKENED FLAT WASHER

3 805048399 1 BOLT M12×95 GB/T5782-2000

##