Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307496 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Steel Pipe Assembly (Part No. 318307496): A Clear Advantage Compared to Competitors

In the field of construction machinery, the performance of key components directly affects the overall operating efficiency and stability of the machine. The XCMG XE2000 excavator’s steel pipe assembly (part no. 318307496) demonstrates unparalleled advantages compared to numerous competing products.

I. Materials and Craftsmanship – Building a Robust and Durable Foundation

Strict Material Selection: The XCMG XE2000’s steel pipe assembly uses specially formulated high-strength steel, whose yield strength far exceeds that of ordinary steel pipe materials. This means that under the same pressure and load, XCMG’s steel pipe assembly has a lower risk of deformation. Compared to some competitors using conventional materials, XCMG steel pipes exhibit stronger fatigue resistance when facing high pressure and strong impacts under complex working conditions. For example, during high-intensity operations at a large open-pit mine, XCMG XE2000 excavators operated continuously for months without damage to their steel pipe components. In contrast, a competing excavator operating concurrently experienced frequent problems such as thinning pipe walls and leaks due to insufficient steel pipe strength, severely impacting construction progress.

Precision Manufacturing Support: XCMG strives for excellence in steel pipe manufacturing, employing advanced cold drawing processes and precision machining technologies. The most automated and longest-stroke cold drawing machine in Asia is used by XCMG, ensuring high precision and excellent surface quality of the steel pipes. Regarding dimensional accuracy, XCMG steel pipe components are strictly controlled within extremely small tolerances, achieving perfect matching with other excavator parts and reducing the risk of leakage and energy loss due to assembly gaps. Conversely, some competing products, due to limited manufacturing capabilities, have unstable dimensional accuracy in their steel pipes, affecting not only the overall performance of the equipment but also increasing maintenance frequency.

Strict Quality Control: XCMG has established a comprehensive and rigorous quality control system. From raw material procurement to finished product delivery, every step undergoes multiple inspection processes. Each steel pipe undergoes rigorous pressure testing and non-destructive testing to ensure reliable quality. In contrast, some competitors simplify their quality inspection processes to reduce costs, resulting in inconsistent product quality and posing numerous risks to users.

II. Performance – A Powerful Guarantee of High Efficiency and Stability

Highly Efficient Hydraulic Transmission: The XCMG XE2000’s steel pipe assembly features an optimized internal structure design, allowing for smoother hydraulic oil flow and less pressure loss. This enables the hydraulic system to respond quickly to operating commands during excavator operation, achieving precise and efficient motion control. For example, in excavation operations, the XCMG XE2000 can rapidly transfer digging force to the bucket, resulting in agile and powerful digging movements. Compared to competing excavators, it can complete more digging tasks in the same amount of time, significantly improving construction efficiency.

Adaptable to Complex Working Conditions: Whether in the scorching desert environment, the cold and snowy northern mines, or the damp and dusty construction sites, the XCMG XE2000’s steel pipe assembly operates stably. It possesses excellent corrosion resistance and freeze resistance, enabling it to adapt to various climatic conditions and harsh working environments. In contrast, some competing products’ steel pipe components are prone to corrosion and cracking in extreme environments, limiting the equipment’s application range. For example, in a port construction project in a coastal area of southern China, where humidity and air salt content are high, the steel pipe components of some competing excavators showed severe corrosion after a period of use, while the XCMG XE2000’s steel pipe components maintained stable operation thanks to their superior corrosion resistance.

Long lifespan and reduced costs: Thanks to high-quality materials and sophisticated craftsmanship, the XCMG XE2000’s steel pipe components boast an exceptionally long service life. During long-term, high-intensity operation, its wear and tear is far lower than competing products. This not only reduces downtime due to component replacement and lowers maintenance costs but also increases equipment uptime, creating greater economic benefits for users. According to actual usage data, under normal maintenance conditions, the XCMG XE2000’s steel pipe components have a service life 30%-50% longer than some competing products.

III. Adaptability and Compatibility – Perfect Fit to the Whole Machine System

Customized Design: The XCMG XE2000’s steel pipe assembly is customized based on the excavator’s hydraulic system and structural layout, achieving a high degree of compatibility with the entire machine. The routing and connection method of each steel pipe are meticulously planned to ensure that within a limited space, the hydraulic system’s operational needs are met while maintaining a compact and aesthetically pleasing structure. This customized design allows the steel pipe assembly to work more smoothly with other parts of the excavator, avoiding vibration and noise problems caused by incompatibility. In contrast, some competing products use a universal steel pipe assembly design, which may lead to compatibility issues when adapting to different excavator models, affecting equipment performance.

Strong System Compatibility: XCMG emphasizes the compatibility of the steel pipe assembly with the machine’s electrical and control systems. In today’s era of intelligent development, the excavator’s electrical and control systems play a crucial role in the equipment’s operational accuracy and fault diagnosis. The steel pipe assembly of the XCMG XE2000 excavator is perfectly integrated with the machine’s electrical and control systems, accurately transmitting various signals to ensure stable operation under complex working conditions. For example, when the hydraulic system pressure of the excavator changes, the steel pipe assembly can promptly transmit the signal to the control system, which then makes precise adjustments according to preset programs, ensuring the safety and reliability of the equipment. In contrast, some competing products, due to poor component compatibility, may experience signal transmission delays and misjudgments, affecting normal operation.

In summary, the steel pipe assembly (part number 318307496) for the XCMG XE2000 excavator surpasses competing products in all aspects, including materials, workmanship, performance, and compatibility. Choosing XCMG means choosing efficient, stable, and durable construction machinery solutions to safeguard your projects and create greater value.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

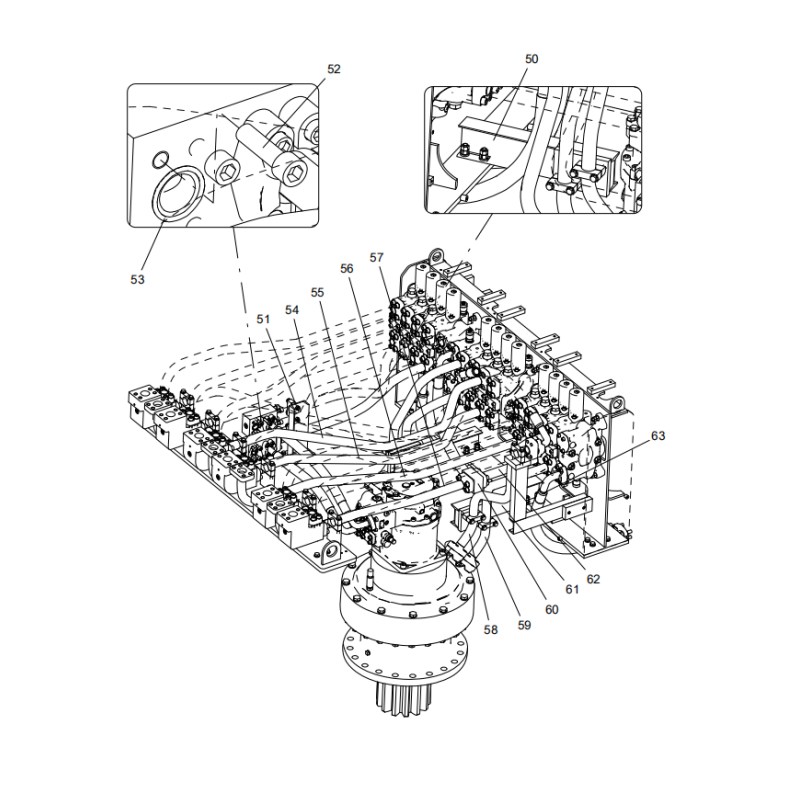

318307498 TURNTABLE MAIN OIL PIPELINE

50 318307500 1 BRACKET

51 318307521 1 BRACKET

52 805046396 8 SCREW M14×50 GB/T70.1-2008

53 803130023 2 ORING 37.69×3.53 AS568

54 318307476 1 STEEL PIPE ASSEMBLY

55 318307496 1 STEEL PIPE ASSEMBLY

56 318307485 1 STEEL PIPE ASSEMBLY

57 318307482 1 STEEL PIPE ASSEMBLY

58 318307514 1 STEEL PIPE ASSEMBLY

59 318307513 1 STEEL PIPE ASSEMBLY

60 318307473 1 BLOCK

61 318307501 1 BRACKET

62 318307487 1 STEEL PIPE ASSEMBLY

63 804414168 1 HOSE ASS’Y

##