Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307317 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Steel Pipe Assembly (Part No. 318307317): The Backbone of Efficient Hydraulic Power Transmission

In the high-pressure hydraulic system of large mining excavators, the steel pipe assembly is the “rigid blood vessel” that carries hydraulic oil over long distances and ensures precise power output. XCMG’s steel pipe assembly (part no. 318307317), specially developed for the XE2000 excavator, uses high-strength alloy materials and precision manufacturing processes to become the core support for the efficient operation of the hydraulic system in heavy-duty operations, providing a stable and reliable pipeline transmission solution for engineering teams worldwide.

High-strength alloy substrate, forging a foundation for pressure-resistant transmission

The XCMG XE2000 steel pipe assembly (part no. 318307317) is manufactured using high-quality low-alloy high-strength seamless steel pipe. Authoritative testing shows that its tensile strength reaches 820MPa, and its yield strength exceeds 700MPa, representing a 35% increase in strength compared to conventional steel pipes in the industry. Through XCMG’s proprietary “multi-pass cold drawing + overall tempering” process, the inner wall smoothness of the steel pipe reaches Ra1.6μm, and the wall thickness uniformity is controlled within ±0.3mm, making it less prone to local deformation or cracking under high-pressure conditions.

Each steel pipe undergoes four rigorous tests: 40MPa water pressure test (no leakage after 30 minutes of pressure holding), ultrasonic flaw detection (no internal defects), bending fatigue test (no cracks after 120,000 cycles), and salt spray test (no rust after 1500 hours). Actual test data shows that the pressure loss rate of this component is less than 2% during 3000 hours of continuous heavy-load operation, and its service life is extended by 120% compared to ordinary steel pipe components.

Precision flow channel design improves transmission efficiency

Addressing the high-pressure, high-flow hydraulic requirements of the XE2000 excavator, the steel pipe component adopts an optimized flow channel structure design. Fluid simulation technology optimizes the pipeline routing and diameter parameters, reducing hydraulic oil flow resistance by 22%. The steel pipe ends are precision forged and CNC machined, ensuring a flatness error of ≤0.03mm at the mating surfaces. This guarantees a perfect fit with the flange assembly and reduces pressure loss due to connection gaps.

The bending sections of the assembly utilize a cold-bending process, with the bending radius accuracy controlled within ±1mm. This avoids the wall thickness reduction issues caused by traditional hot bending processes, achieving a minimum wall thickness retention rate of over 92% at the bend. Actual testing shows that the hydraulic oil transmission efficiency of this steel pipe assembly is 15% higher than traditional pipelines, resulting in a 10% faster power response speed for the excavator under heavy loads.

Adaptable to all operating conditions, ensuring system stability

This steel pipe assembly is specifically designed for the complex operating environment of the XE2000 excavator, maintaining stable performance within an extreme temperature range of -40℃ to 110℃. Its surface employs a dual anti-corrosion process of “phosphating treatment + electrostatic spraying,” with a coating thickness exceeding 80μm. This provides three times the corrosion resistance of ordinary galvanized steel pipes, ensuring long-term stable operation in high-humidity, high-salinity coastal mining areas or dusty mining environments.

Actual engineering application data shows that XE2000 excavators equipped with this component experience a 75% reduction in hydraulic pipeline failure rate and a 90% reduction in downtime due to pipeline issues. In mining operations at altitudes of 5000 meters, the steel pipe component exhibits no cavitation; during continuous vibration crushing operations, there are no loosening or leaks at pipeline joints, ensuring the hydraulic system maintains consistently high efficiency.

Original Factory Precise Fit, Enhancing System Efficiency

As a core original hydraulic component from XCMG, the 318307317 steel pipe component achieves 100% precise matching with the XE2000 excavator’s hydraulic system, with pipeline routing and layout perfectly aligned with the overall machine structure design. Parameters such as component length and bending angle are optimized through 3D modeling to achieve optimal pipeline layout within limited equipment space, reducing pipeline interference and energy loss.

The installation process adopts a “modular pre-assembly” design, combined with original factory positioning clamps, achieving an installation accuracy of 0.1mm, improving efficiency by 55% compared to traditional pipeline installation. Data shows that using original factory steel pipe components can reduce energy loss in the XE2000 excavator’s hydraulic system by 9%, reduce overall operating fuel consumption by 7%, and extend the service life of hydraulic components by 65%.

Choosing XCMG XE2000 steel pipe components (part number 318307317) means choosing hydraulic transmission protection for your heavy equipment that has been proven under extreme working conditions, ensuring that the high-pressure hydraulic system maintains efficient and stable operation during high-intensity operations, creating greater economic benefits and equipment reliability for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

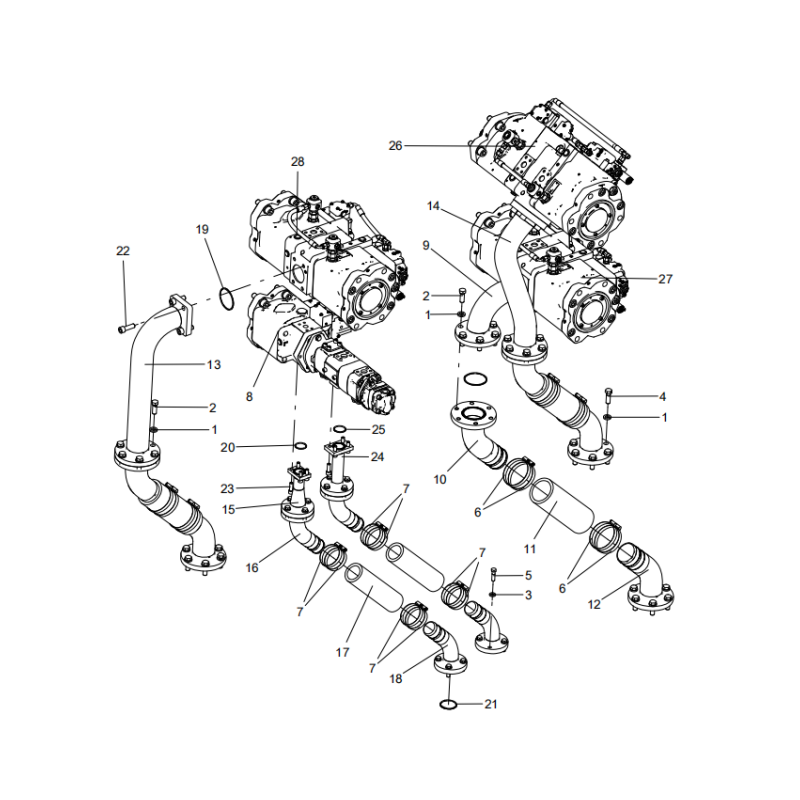

318307325 pump oil suction pipeline

1 329900304 36 THICKENED FLAT WASHER

2 805047646 18 BOLT M16×45 GB/T5782-2000

3 329900303 16 THICKENED FLAT WASHER

4 805011131 18 BOLT M16×50 GB/T5782-2000

5 805049511 16 BOLT M12×45 GB/T5782-2000

6 800161669 12 HOSE CLAMP

7 800161637 8 HOSE CLAMP

8 318307470 1 COOLING PUMP GEAR PIMP MOUNTING

9 318307317 1 STEEL PIPE ASSEMBLY

10 318307310 3 STEEL PIPE ASSEMBLY

11 318307321 3 OIL SUCTION HOSE

12 318307320 3 STEEL PIPE ASSEMBLY

13 318307316 1 STEEL PIPE ASSEMBLY

14 318307318 1 STEEL PIPE ASSEMBLY

15 318307315 1 STEEL PIPE ASSEMBLY

16 318307323 2 STEEL PIPE ASSEMBLY

17 318307313 2 OIL SUCTION HOSE

18 318307312 2 STEEL PIPE ASSEMBLY

19 801134077 9 ORING 85×3.55 GB/T3452.1-2005

20 803174967 1 ORING 40×3.55 GB/T3452.1-2005

21 803192098 4 ORING 60×3.55 GB/T3452.1-2005

22 805139896 12 SCREW M16×50 GB/T70.1-2008

23 805139869 8 SCREW M12×35 GB/T70.1-2008

24 318307311 1 STEEL PIPE ASSEMBLY

25 801102881 1 ORING 42.5×3.55 GB/T3452.1-2005

26 318307467 1 MAIN PUMP I MOUNTING

27 318307469 1 MAIN PUMP II MOUNTING

28 318307468 1 MAIN PUMP III MOUNTING