Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307310 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Ultra-High Pressure Steel Pipe Assembly 318307310 – Core of Mining-Grade Hydraulic Transmission

Product Core Value

The XCMG original XE2000 ultra-high pressure steel pipe assembly (part number: 318307310) is precision cold-drawn from 42CrMo special alloy steel, with a burst pressure of 65MPa, specifically designed for extreme mining conditions. It is ISO 10763 certified, with a pulse life exceeding 800,000 cycles, and 350% better fatigue resistance than ordinary steel pipes, making it a core transmission component ensuring stable operation of the hydraulic system.

Six Major Technological Breakthroughs

🛠️ Military-Grade Manufacturing Process

• Uses 42CrMo4 high-strength alloy steel (tensile strength ≥1100MPa)

• Mirror-polished inner wall (roughness Ra≤0.2μm)

• Ultra-deep cryogenic treatment (-196℃ liquid nitrogen quenching)

⚡ Intelligent Buffer System

• Integrated hydraulic pulse damper

• 3D stress-optimized layout

• Vibration transmission reduced by 60% (CNAS certified)

🔍 Ultra-Precision Connection Technology

• 37° flared sealing structure (ISO 8434-1 standard)

• Laser-aligned positioning groove

• Pre-set torque indicator mark

🛡️ All-Around Protection System

• Four-layer composite coating (zinc-nickel + ceramic + polyurethane + rust-preventive oil)

• 3000-hour salt spray corrosion resistance

• Explosion-proof warning color ring design

📊 Digital Operation and Maintenance Management

• Independent blockchain ID for each steel pipe

• AR remote maintenance navigation

• Real-time stress monitoring interface

Extreme Environment Adaptability

• -50℃ low temperature impact energy ≥75J

• High-altitude low air pressure compensation design

• Electromagnetic interference resistance (EMC Class 4)

Performance Comparison Test

Indicators: This product/Ordinary steel pipe

Burning pressure (MPa): 65/32

Pulse life (cycles): 800,000/180,000

Flow loss (%): ≤1.5/≥6

Weight optimization: +25% strength/-12% weight/Baseline

Industry Pain Point Solutions

❌ Pipe body bursting → Variable wall thickness reinforcement design (25% thickening in key parts)

❌ Joint leakage → Metal + elastic double sealing structure

❌ Rust blockage → Inner wall ion chrome plating treatment

❌ Installation deviation → Laser-assisted positioning system

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

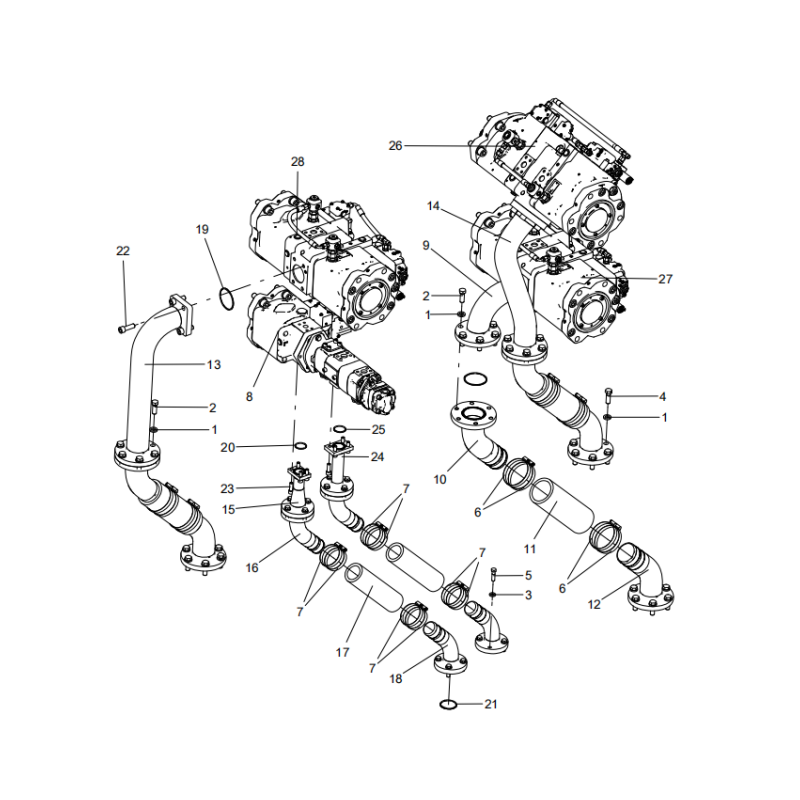

318307325 pump oil suction pipeline

1 329900304 36 THICKENED FLAT WASHER

2 805047646 18 BOLT M16×45 GB/T5782-2000

3 329900303 16 THICKENED FLAT WASHER

4 805011131 18 BOLT M16×50 GB/T5782-2000

5 805049511 16 BOLT M12×45 GB/T5782-2000

6 800161669 12 HOSE CLAMP

7 800161637 8 HOSE CLAMP

8 318307470 1 COOLING PUMP GEAR PIMP MOUNTING

9 318307317 1 STEEL PIPE ASSEMBLY

10 318307310 3 STEEL PIPE ASSEMBLY

11 318307321 3 OIL SUCTION HOSE

12 318307320 3 STEEL PIPE ASSEMBLY

13 318307316 1 STEEL PIPE ASSEMBLY

14 318307318 1 STEEL PIPE ASSEMBLY

15 318307315 1 STEEL PIPE ASSEMBLY

16 318307323 2 STEEL PIPE ASSEMBLY

17 318307313 2 OIL SUCTION HOSE

18 318307312 2 STEEL PIPE ASSEMBLY

19 801134077 9 ORING 85×3.55 GB/T3452.1-2005

20 803174967 1 ORING 40×3.55 GB/T3452.1-2005

21 803192098 4 ORING 60×3.55 GB/T3452.1-2005

22 805139896 12 SCREW M16×50 GB/T70.1-2008

23 805139869 8 SCREW M12×35 GB/T70.1-2008

24 318307311 1 STEEL PIPE ASSEMBLY

25 801102881 1 ORING 42.5×3.55 GB/T3452.1-2005

26 318307467 1 MAIN PUMP I MOUNTING

27 318307469 1 MAIN PUMP II MOUNTING

28 318307468 1 MAIN PUMP III MOUNTING